TemplateA4_v20130506

27

11-1

11-2

11-4

11-5

11-6

11-7

11985432

2-2

2-2-1

4-1

4-20

9-1

9-9

9-10

10

11-8

11-3

(....)

9-5

9-6

8-5-1

8-5-2

8-5-3

8-5-4

8-5-5

8-5-6

8-5

8-4

8-4-1

8-4-17

(....)

8-3

8-3-1

8-1

8-1-1

8-2

8-2-1

8-2-2

Example:

P

SV

;Triggerpressuresafetyvalve6bar(appendix)

(Fromorderspecication<=nominalpressureunit)

P

E

;nalpressure5.4bar

Safetyvalve,codeletterDGH

P

SV

x0.9[P

SV

>=3bar];P

SV

-0.3bar[P

SV

<3bar]

Safetyvalve,codeletterH

P

SV

-0.5bar[P

SV

=3bar]

(Fromorderspecication)

P

A

;Operatingpressure1.2bar(congurablerangebyunittype)

P

A+

;Upperoperatingpressuretolerance0.2bar(default)

P

A-

;Loweroperatingpressuretolerance0.2bar(default)

(Fromorderspecication)

P

+

;Positivepressure0.3bar(default,recommended)

P

0

;Displayedvalue,message:P

A

- P

A-

- P

+

=1.2-0.2-0.3=0.7bar

(e.g.:=P

static

+ P

steam

+ P

dynamic=0.7bar

)

Main switch on;

SPC terminal with

main menuon;

Fields and messages

withbacklighting

areactive.

- Menu 2: Module

extension option

required;

- Menu 3:Check,change

date,time

- Menu 4:Check,change

language

- Menu 5: Not

possible, not necessary;

- Menu 8: Defaults

can be still changed

after start or as

required:

- Menu 8-1-1:

Application to

change P

e

, P

A

- Menu 8-2-2: Can be

switched off/on if

drainage exists;

- Menu: 8-3-1: Install

on request, then

enable;

- Menu 8-4-1...17:

Group error message

assignments; enable/

disable

on request;

- Menu 9:

-Menu9-1:Pleasenote;

-Menu9-5:Input,select

nominalcapacity;

-Menu9-6:Execute;

-Menu9-7:Execute;

-Menu9-8:Check,

change;

-Menu9-9:Operating

rangedetermined,

execute.

Example:

Actualpressure1.4bar

Duopumpunit;pumps,valvesnotON.

Vesselcontent0%,errormin.priming

waterON(errorno.:19;10).

top-upvalve230v,self-monitoring,ON;

Noimpulsewatermeter,top-uptime<1minute.

Gassensorenabled,degasicationmodenormal

(DegassingnotONduetomin.primingwater).

Example:

Summer time is ON

date:23.10.2010.

Time:

18.00hours,

12minutes,57seconds.

Linebelow:

Functionalassignmentfor

sensor buttons.

Change menu

Date,time

Werkingsindicator

Start

Pressure

settings

Turkish

Operational

calibration

Saveconguration

on SD

ID Vessel

ID Vessel

Example:

Thenominalvolume

(seesection5.2)is

shownonthevessel

labelorSPCIDsticker.

Thiscorrespondstothe

vesselcapacitywiththe

letterA,BorC.

Forexample:

A-200

B-200

C-200

(....)

Read

manual

Operating

Menu

Service

menu

Order number

Unit

information

Version

information

Start

Maintaining

Error list

Operating hours

Top-up,

overowspill

Start

menu

Conguration

menuLoginmenu

Degassing

Manufacturer,

supplier

(traceability)

Unit,vessel,

vesselcalibration

(test)

Controlunit,

software,hardware

(traceability)

Date:Startof

commissioning,

vesselcalibration

(statistics)

See:

Maintaining

Errorhistory,nolongeractive

errors,errorno.,date,time

(analysis)

(Statistics)

Quantities,

times

(statistics)

Degassing

procedure

ON,OFF

(TestcycleON,

see8-5-2)

Distribution of

sleepintervalsto

weekdays(next

page)

Gassensor,sensor

connectionarray

required(optional)

Activated

Controlled

Standby

Normal

Operating

pressure menu

Closing

times

Language

menu

Error

message

Pressure

(....)

Phase

monitor

Date/ Time

menu

Sensors

valves

Minimum

pressure limiter

Data transfer

menu

Level

Top-up

Drain

Fast

Pressure

Operating

pressure

SPC terminal

SD-kaart

German

Main menu

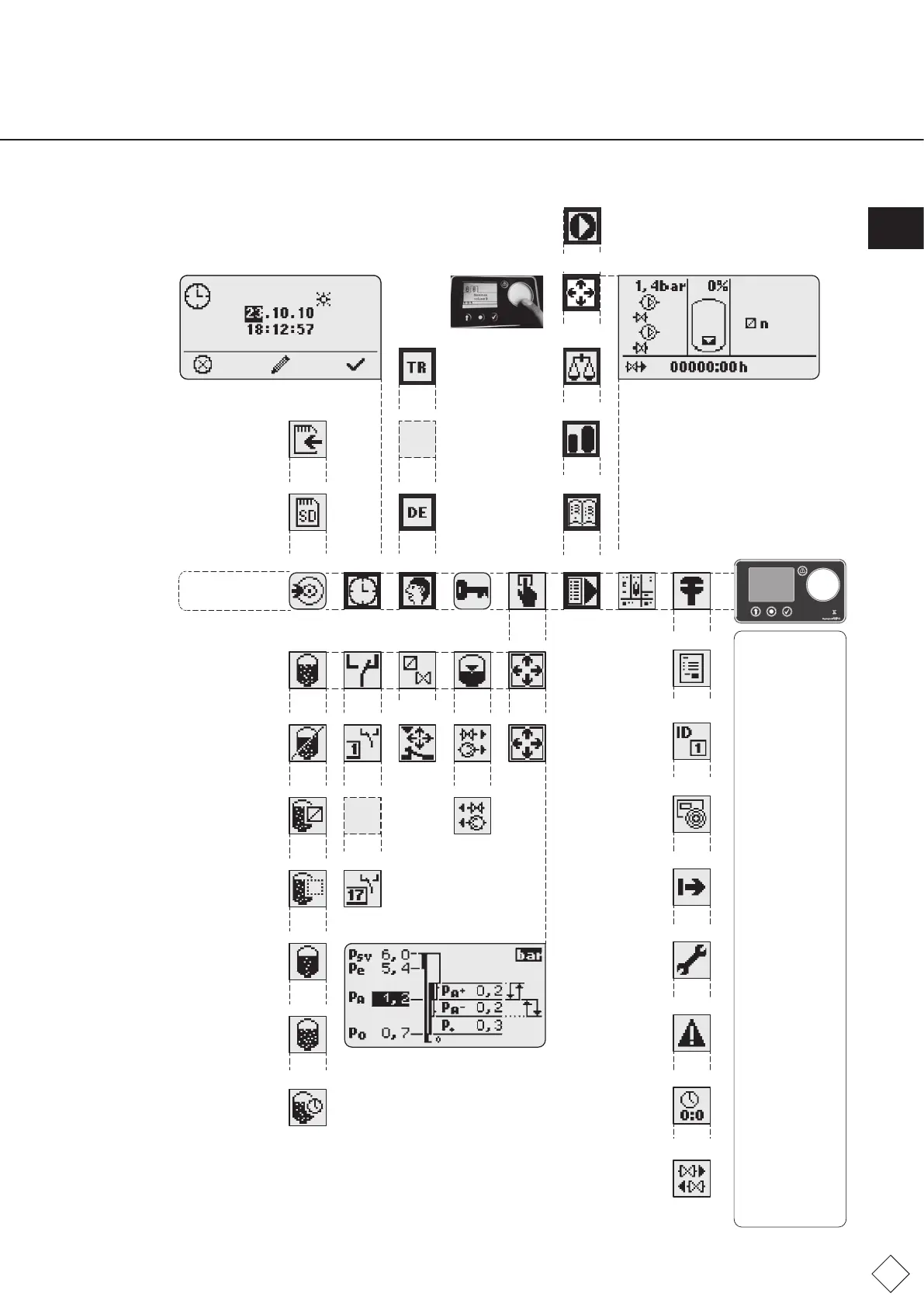

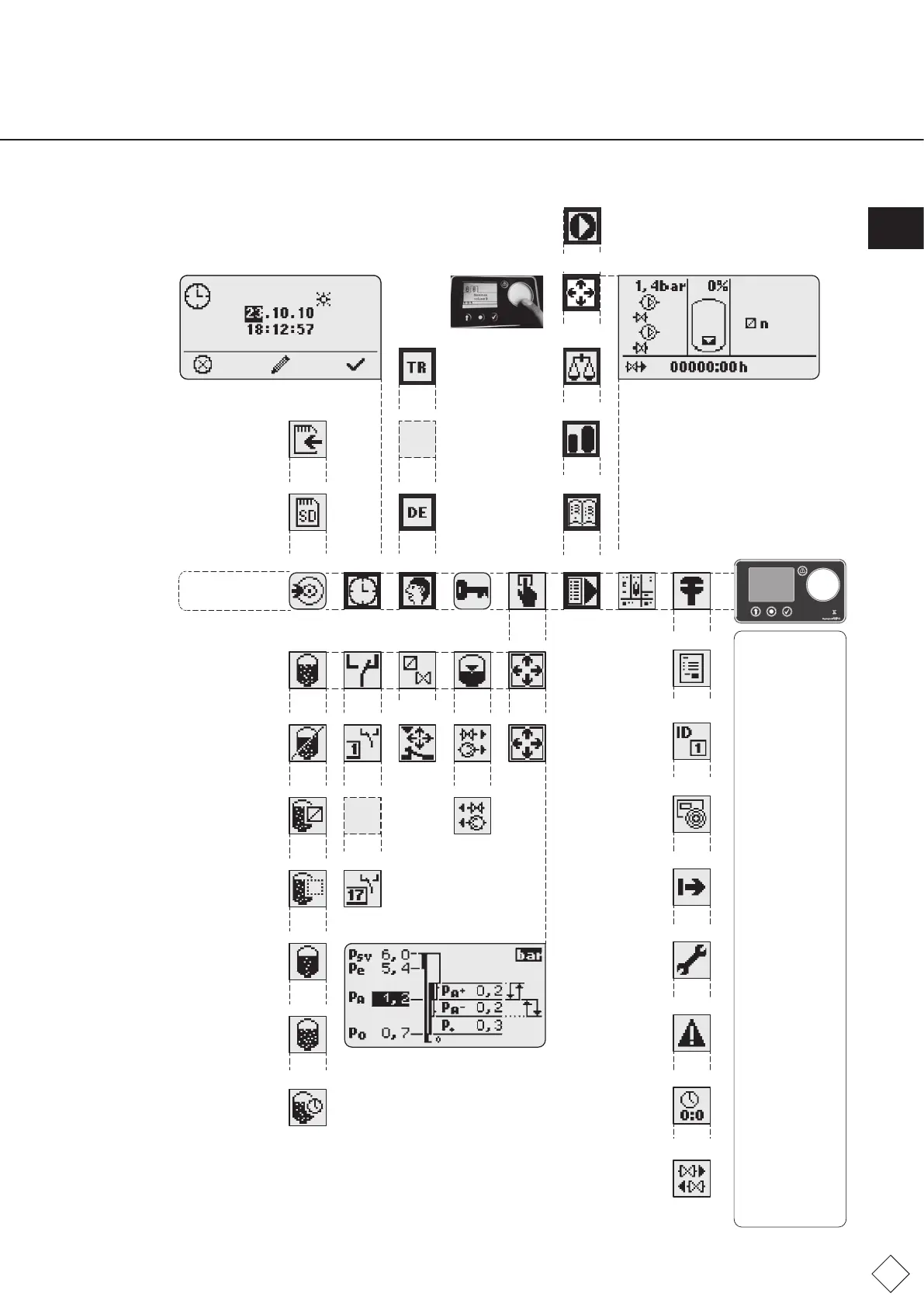

7.3 Overview menu options

Fig. FM.038.V02.15

ENG

Loading...

Loading...