TemplateA4_v20130506

35

Maintaining

Maintain. 1!

Maintain. 2!

Maintain. 3!

Maintain. 4!

Message:

Message:

Message:

Message:

Carry out

equipment service!

Inspect vessel

internally!

Consider recurring

inspections, see general

safety instructions.

Carry out strength

inspection vessel!

Carry out recurring

inspection of electrical

equipment!

After completion of

service or planned

inspection the

applicable

service has to

be confirmed.!

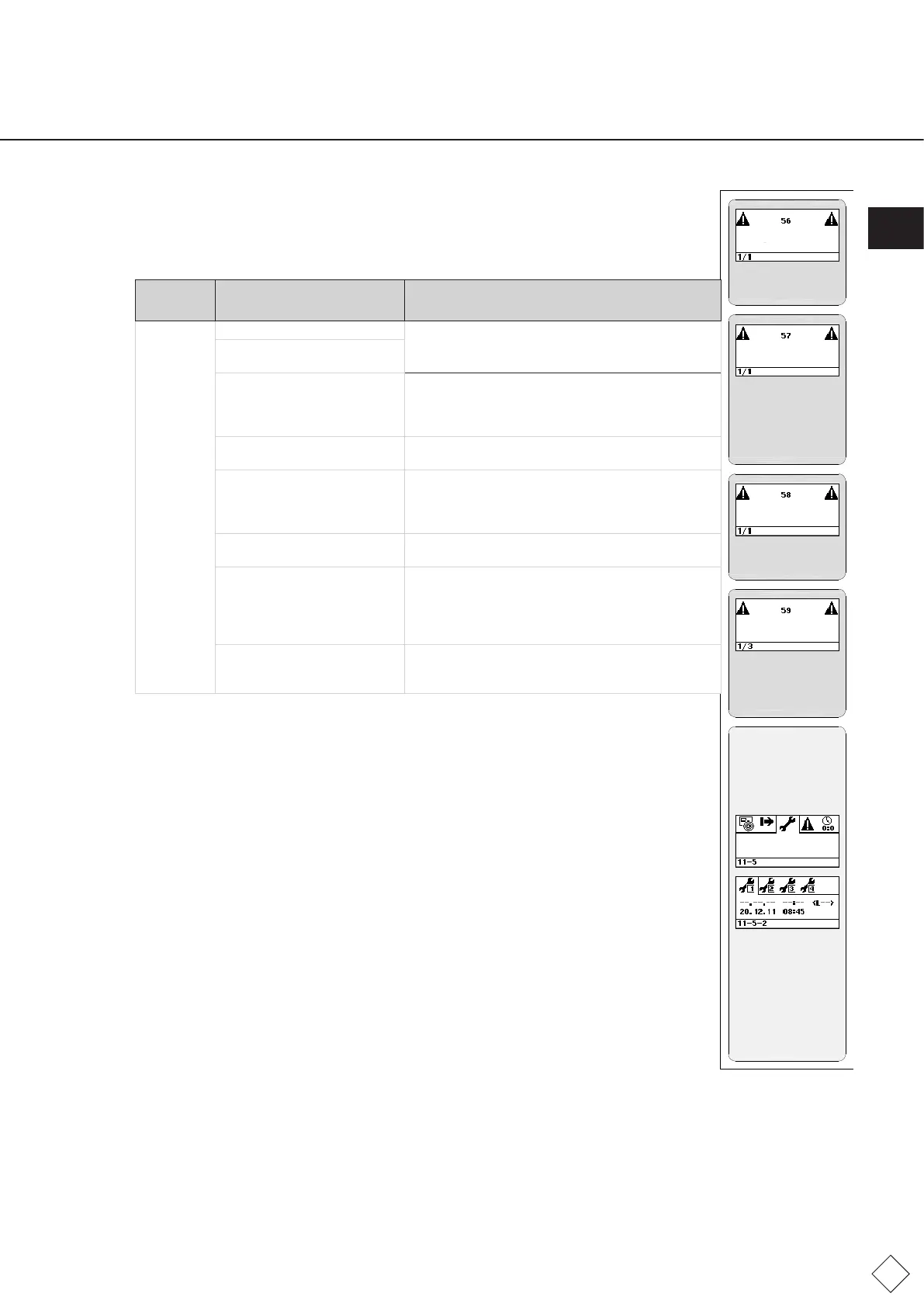

Example:

Service 1 is due at:

20.12.2011; it results

in a message at this

day. After completion

of service, it should

be confirmed with the

[enter] key (entry

of date and time

in upper blank line).

8. Maintenance

Electricalsupplymustbedisconnectedpriortoconductinganymaintenance.Electricalsupplymustbe

disconnectedpriortoconductinganymaintenance.Tosupplement,orinadditionto,thestipulations

madeintheoverallproject,performthefollowing:

Service

interval

Object, standard scope of supply Service activities, measures

Annually Particlelter3.8)* Cleanlterinsertandhousing

Particlelterback-owsecurity

(onlywheninstalled)

Air-intakepreventer,

bleedervalve1.2)*,

automaticbreather3.18)*

Cleanandcheckfunction.Unscrewthecapandtake

outtheinnerspringandball-bearingforcleaning.Re-

assembleinreverseorder.Screwthecapbackonand

open it with a single turn.

Primervalve3.10;3.11)* Checkandresetthepre-setsasindiagrams(see

appendix2;sealthevalve)

Pump3.3÷3.6)*,

valve1,2,3.12,3.13)*,

valve3)*,

watermeter3.14)*

Functioncheck.Tobecarriedoutmanuallybytrained

andcertiedpersonnel.Otherinspectionscanbe

doneduringoperationoftheFlamcomatequipment

(observe).Bleedpumps(exceptforM/D60)

Controlunit3.19;3.20)*,

conguration

Inspectandrestoretherequiredsettings(overview

menu)

Vessel1)*,

pumpmodule3)*

Inspectandrepairtheleak-tightnessofallhydraulic

connectionstothewaterareas.Checkthescrew

connectionsfortightness,checktheexteriorfor

damage,deformationorcorrosionandrestore to

operational readiness.

Safetyvalve3.16)* Functioncheck.Tobecarriedoutmanuallybytrained

andcertiedpersonnel.Thisrequiresthelockshield

valve2.1)*ontheconnectionassembly.

)*positions,page18-21.

8.1 Vessel draining/relling.

Ifdrainingofexpansionwaterinthemainvesselorauxiliaryvesselsisnecessary,pleaseconsiderthe

followingorderofactions:

• Recordtheactualvolumelevel(%)asshownonSPCcontrolunitdisplay.

• SwitchthecontrolunitOFF.

• Closethelockshieldvalvesontheexpansionpipe(systeminletandoutlet)andontheconnectingarray

(vesselinlet,outlet)

• Closetheisolatingvalveatthetop-upconnection.

• Carryouttherequiredworkonthevessel(drain,service,repairetc.).

• SwitchthecontrolunitONresettostartmenu(overviewofmenuoptions;menuline11-5-7)**andrun

startmenuprocedure(overviewmenuoptions;menu-line9...9-9)***.

• Fillthemainvesseland(ifapplicable)theauxiliaryvessels.Theself-adjustingvolumelevelcanbe

monitoredinthedisplayofthecontrolunitandthellingprocessshouldbeinterruptedatreachingthe

previouslyrecordedtargetvalue.

Note:whenarellbiggerthanthedefaultsettingforminimumvesselllingvolumeisrequired(6%),

pleaseswitchoffthede-aerationfunction(overviewmenuoptions;menu-line8-5-1).Thellingshould

preferablytakeplaceoverthevesselconnectionvalve(marking).Ifboththemainandauxiliaryvessels

needlling,openthelockshieldvalveoneachvesselconnection(owandreturn).Makesurethatthe

volumeleveldetectionismadebyusingthevolumesensorofthemainvessel.

• Disconnectthellingequipment.

• Openallpreviouslyclosedvalves(seal)andbleedthepump(s).

• Optionallythede-aerationfunctioncanbeswitchedONagain.

• The operational mode has been restored.

)** Thereare3questionsinthismenuitem.Onlywhentheseareconrmed,theresettakesplace.

)*** Atthemomentofrestartingthesystemsomelogicalerrorsmayarousethatareself-acknowledgingoracknowledged.

Fig. FM.039.V01.15

ENG

Loading...

Loading...