TemplateA4_v20130506

23

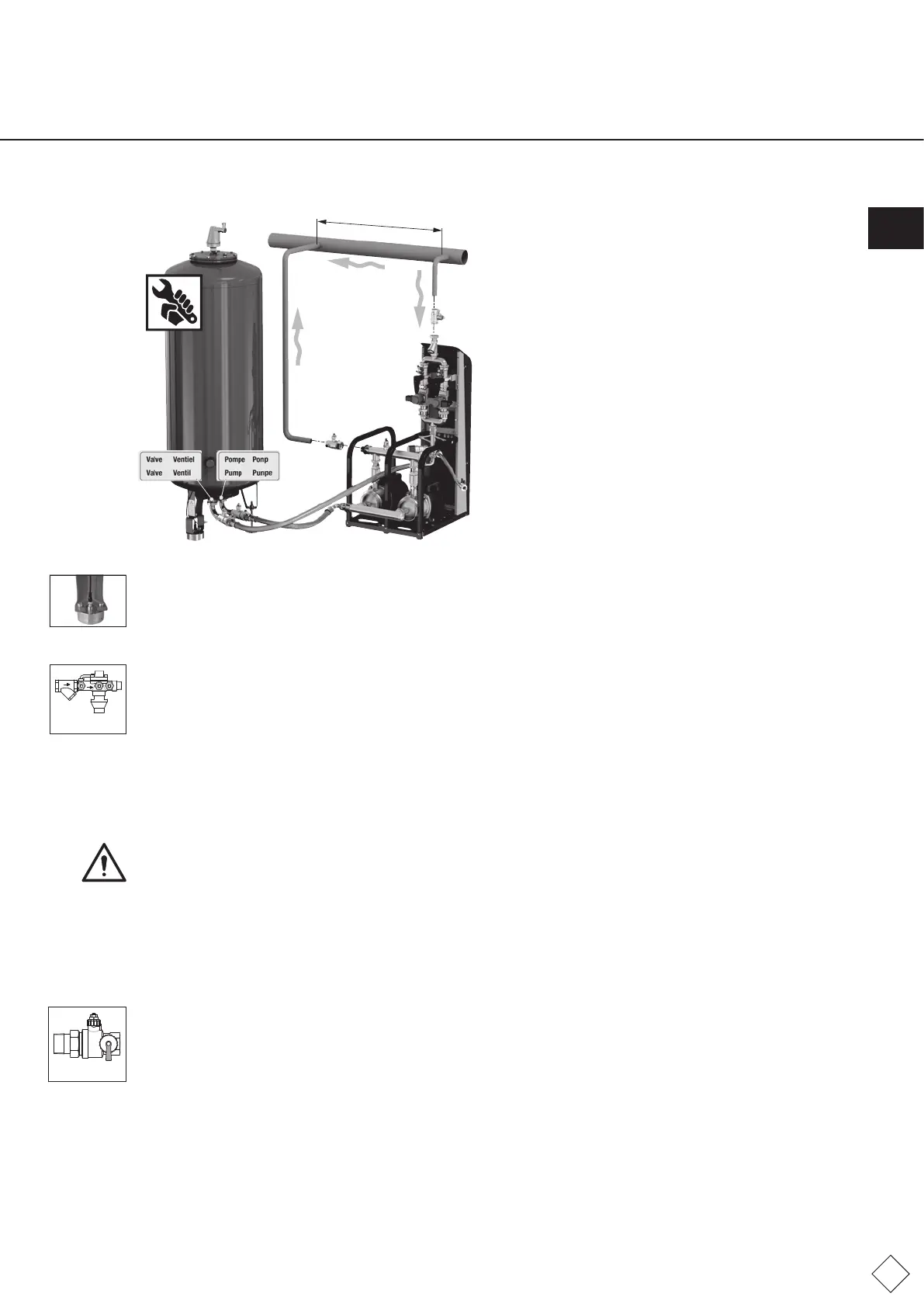

Takenoteofthelabels‘pump’and‘valve’ontheconnectionsand

connectuptheappropriateconnectionfromthepumpmodule

(valve)tothepump(valve)onthevesselconnection.

Donotcrosstheseconnectionsand,ifnecessary,mountthe

vesselconnectionangesoastoenableparallelpipetting.Use

theatsealssupplied.

• Connectthesignallineviathequick-releaseconnectiontothecapacitysensor.Screwthisconnectionentirelyintothe

connector(protectionclassIP67).

• Openthelockshieldvalveontheconnectionassemblybetweenthevessel(basicvessel,intermediatevessel)andcontrolmodule.

6.3 Top-up connection

Thetop-upconnectionshouldbeconnectedtothecontrolunit.Assuredtop-uprequiresanaveragesetfeedpressureof

approx.4-6bar(max.8bar).Highfeedpressuresmayrequiredevicestopreventwaterhammer(pressurereducingvalve).

Appendix 1 shows the installation diagram and example installation.

Pleaseobservethefollowingspecicationsbeforellingandcommissioningthepressure-expansionautomat:

• Installthefeedtothetop-uphosewithshut-offvalve(asdelivered).

• Avoidanytensileloadsonthehose,bendingradiioflessthan50mmandcontractions.

• Ifthetop-upfeedisconnectedtothewatermain,abackowpreventerwithltermustbeconnectedinseriesincompliance

withEN806-4/EN1717.Installthisaccessoryhorizontallyandtashut-offvalvebeforethisassembly(note:cleanlter

regularlyandchangeltersasandwhenrequired).

Caution:Connecttheshut-offvalvetothetop-upintake.

6.4 Drain connection

Tosafelyroutethevolumeowstobedischargedatthesafetyvalve(Pos.3.16),backowpreventer(accessory,top-up)andthe

atmosphericpressurecompensationconnection(Pos.1.3)adrainisrequiredinthevicinityoftheFlamcomatequipment.

• Installadrainfunneland,ifnecessary,adrainpipeforthebackowpreventer.

• Whenadischargepipeisconnectedtothesafetyvalve,theconnectionmustbekeptopentoatmosphericpressure.An

atmosphericfunnelfromtheFlamcoproductcataloguecanbettedforthispurpose.

6.5 System connection

Thesystemconnectionshouldbeconnectedtotheheatingorcoolingsystem.

Appendix 1 shows the installation diagram and example installation.

Pleaseobservethefollowingspecicationsbeforellingandcommissioningthepressure-expansionautomat:

• Theconnectionshouldpreferablybemadeinthereturnlineoftheheatingsystem.Pleasenotethatatemperatureatthe

systemconnection>70°C(...80°C)wouldexceedthepermissiblepump/diaphragmloadandpossiblyleadtodamage

tocomponents.(Completeinsulationoftheexpansionpipemayincreasethetemperatureloadonthecontrolunitandthe

diaphragm).

• Makesurethatthisconnectionisdirectlyconnectedtotheheatgenerator,andthattherearenoexternalhydraulicpressure

inuencespresentatthepointofentrainment(e.g.hydraulicbalancers,distributors).

• Theowdetermineshowyoushouldinstalltheexpansionlines.Whenttingexpansionlinestothereturn>5minlength,use

pipesofatleastonenominaldiameterlargerthanthatofthepumpmodule.Avoidadditionalloadstothesystemconnectionof

thecontrolunit(e.g.fromheatexpansion,owoscillations,deadweights).

• Equipmentwithowtemperatures>100°Cmusthaveaminimumpressurelimiterttedintheexpansionline(systemdrain,

valvedrainpipework).ThearrangementiscontainedinAppendix1.InapplicationsinaccordancewithDINEN12828:2003(D),

thislimiterisonlyenvisagedforuseifthepressureholdingdevicedoesnothaveanautomatictop-upsystem.

>1 m - < 2 m

Fig. FM.034.V01.15

Non-returnvalve

Fig. FM.035.V01.15

Lockshieldvalve

Fig. FM.036.V01.15

ENG

Loading...

Loading...