TemplateA4_v20130506

10

Electrical hazards:

Theprotectionclassofelectricallyoperatedcomponentspreventspersonalinjurybyelectrocution,whichcanbefatal.The

protectionclassisusuallyIP54(5:Dustprotected,protectedagainstingresswithawire;4:protectedagainstsplashingwater).

Thecontrolunitcover,thecoverofthepumpfeed,thethreadedcableglandsandthevalveconnectorplugsmustbeinspected

foreffectivenesspriortocommissioning.Theinstalledpressureandvolumesensorsareoperatedwithprotectiveextra-low

voltage.

Avoidweldingworkonadditionalequipmentwhichiselectricallyconnectedtothecontrolunit.Strayweldingcurrentoran

improperearthconnectioncouldleadtothedangerofreanddamagetopartsoftheunit(e.g.thecontrolunit).

4.15 External forces

Avoidanyadditionalforces(e.g.:forcescausedbyheatexpansion,owoscillationsordeadweightsontheowandreturn

lines).Thesecanleadtodamage/leaksinwater-bearingpipework,lossofstabilityoftheapplianceandfurthermoretofailure

connectedwithsubstantialmaterialdamageandpersonalinjury.

4.16 Inspection prior to commissioning, maintenance and re-inspection

TheyguaranteeoperationalsafetyanditsobservanceinlinewithapplicableEuropeanregulations,Europeanandharmonised

standardsandadditionalnationalregulationsoftheEUmemberstatesforthiseldofapplication.Therequiredinspectionsmust

bearrangedbytheowneroroperator;aninspectionandmaintenancelogbookforschedulingandtraceabilityofmeasurestaken

mustbekept.

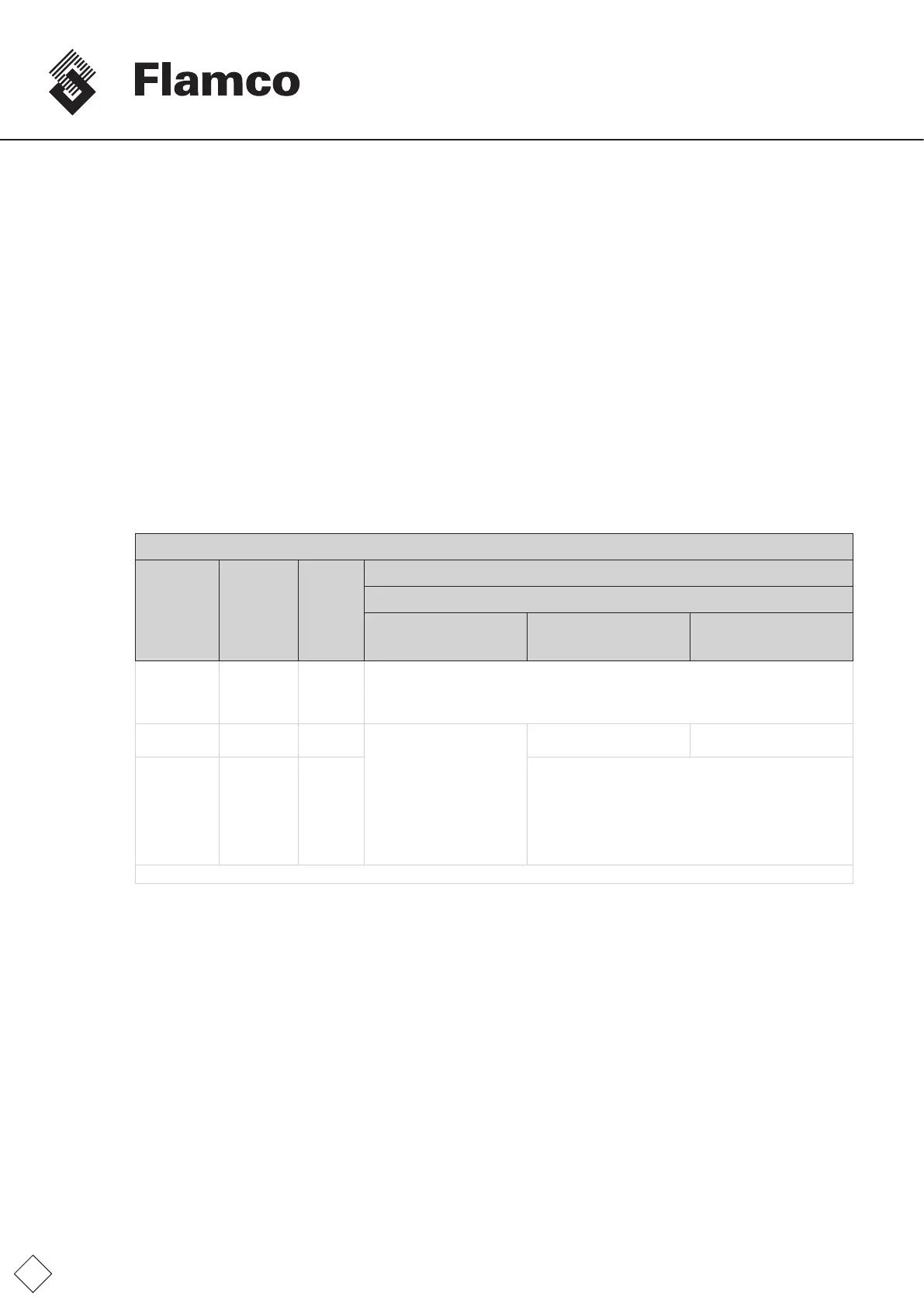

Tests in line with the German ordinance on operational safety (BetrSichV, June 2015):

Pressure equipment, vessels (§14; 15)

Category [see

appendix II

of Directive

2014/68/EU,

diagram 2)

Nominal ves-

sel capacity

[litres]

Inspection

prior to

commis-

sioning

[§14]

inspector

Re-inspection [§15 (5)]

Timeframe, maximum period [a] / inspector

External inspection Internal inspection Strength inspection

II 200- 300 /

3 bar

Qualied

Person

(QP)

Maximumperiodnotdened.Themaximumintervalmustbeestablishedbythe

Operatoronthebasisofinformationprovidedbythemanufacturercoupledwith

practicalexperienceandchamberload.Theinspectionmaybecarriedoutbya

Qualiedperson.

III 400- 10000

/ 3 bar

Nolongerapplicable

[§15(6)]

5 / QP 10 / QP

[§15(10)]Inthecaseofinternalinspectionsthevisual

inspectionmaybereplacedbysimilarproceduresand

inthecaseofstrengthteststhestaticpressuretest

maybereplacedbysimilar,non-destructiveprocedures

if said tests would not otherwise be possible due to

systemdesignornotsignicantduetothesystem

mode of operation.

Maintenanceofequipment,interiorandstrengthinspection,seemaintenance,Ch.8.

InotherMemberStatesoftheEC,therequiredtestsforthepressureequipmentinlinewithdirective2014/68/EUasdenedin

the national rules must be performed.

4.17 Electrical equipment inspections, routine inspection

Withoutprejudicetotheconsiderationsoftheinsurer/Operator,itisrecommendedthattheelectricalequipmentoftheFlamcomat

beinspectedanddocumentedtogetherwiththeheating/coolingunitnolessthanevery18months

(seealsoDINEN60204-12007).

Loading...

Loading...