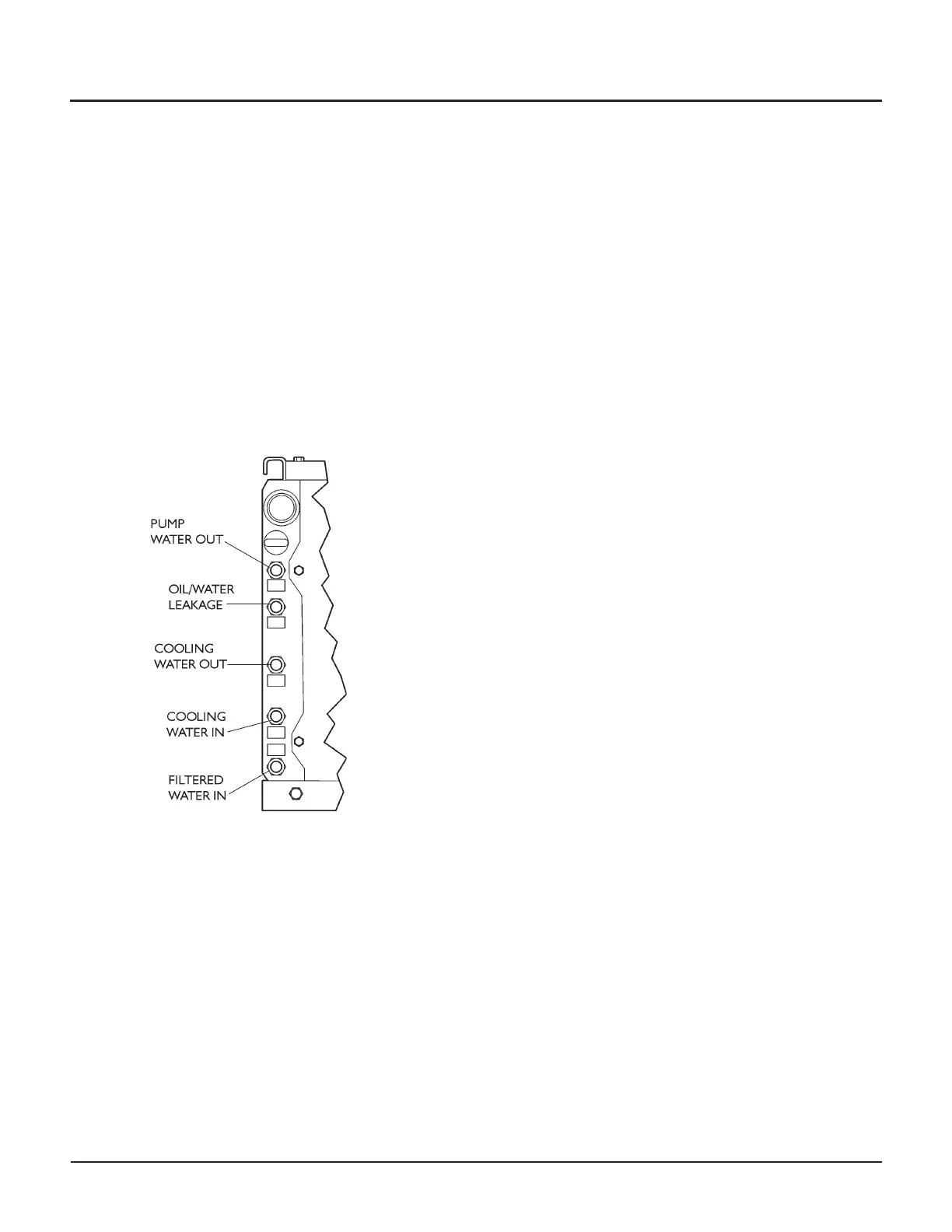

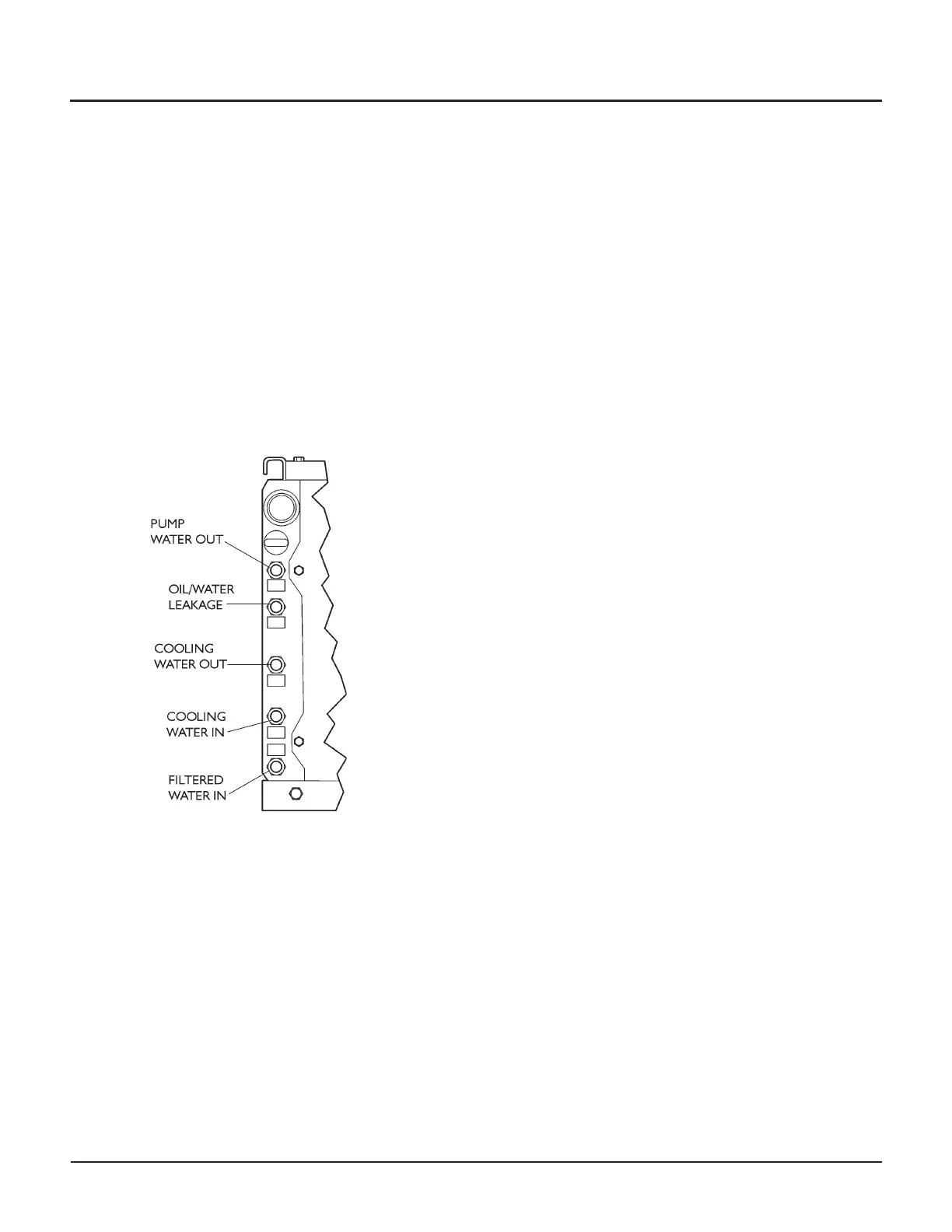

Water interface connections

Please note the following:

•

Flow recommends that you install manual on/off

valves in the inlet water and cooling water lines. Lo

-

cate valves as close as possible to the pump interface

connection to make them easier to service.

•

Coolant water lines must be made from non-corrosive

pipe or rubber hose. Rubber hose per SAE Standard

20R1, 30R1, or equivalent is recommended.

•

Cutting water lines (from the filtering system to the

intensifier pump) must be as short as possible and

must be constructed of PVC, copper, or equivalent.

Do not use galvanized iron piping—it will introduce

minerals to the water, which will shorten orifice life.

Making the interface connections

•

Connect inlet water line to FILTERED WATER IN.

•

Connect LEAKAGE WATER to the appropriate drain or

bucket (can contain oil).

•

Connect BLEED-DOWN WATER to the appropriate

drain.

Note: Purge the inlet water lines of debris before com

-

pleting the connection to the pump.

10 | M-390 © Flow International Corporation

HYPERJET™ 94i-S AND 94i-D PUMPS

Loading...

Loading...