Servicing the heat exchanger

This service procedure is a test to see if the heat

exchanger is leaking water into the oil system. The

oil-to-water heat exchanger controls heat build-up in

the hydraulic oil. The heat exchanger requires no rou

-

tine maintenance.

If the hydraulic oil looks milky but doesn't contain air

bubbles, the oil is contaminated with water. This can be

caused by contaminated oil in the reservoir, excessive

condensation in the reservoir, a missing reservoir filler

cap, or a leaky heat exchanger.

Note: A continual rise in oil level is a sign of cata

-

strophic heat exchanger failure.

Service steps

WARNING

Place the main electrical disconnect in the OFF

position and bleed down all high-pressure lines.

Place an Out of Service tag on the main electrical

disconnect and lock it out. Failure to do so can result in

equipment damage or injury to personnel.

1. Shut down the system.

2. Drain the contaminated oil from the reservoir. If you

see a large amount of water in the oil, the hydraulic

oil system must be completely drained to remove all

water, including intensifier, hydraulic pump, filter,

and hoses.

See Checking the hydraulic oil and Cleaning a con

-

taminated hydraulic system.

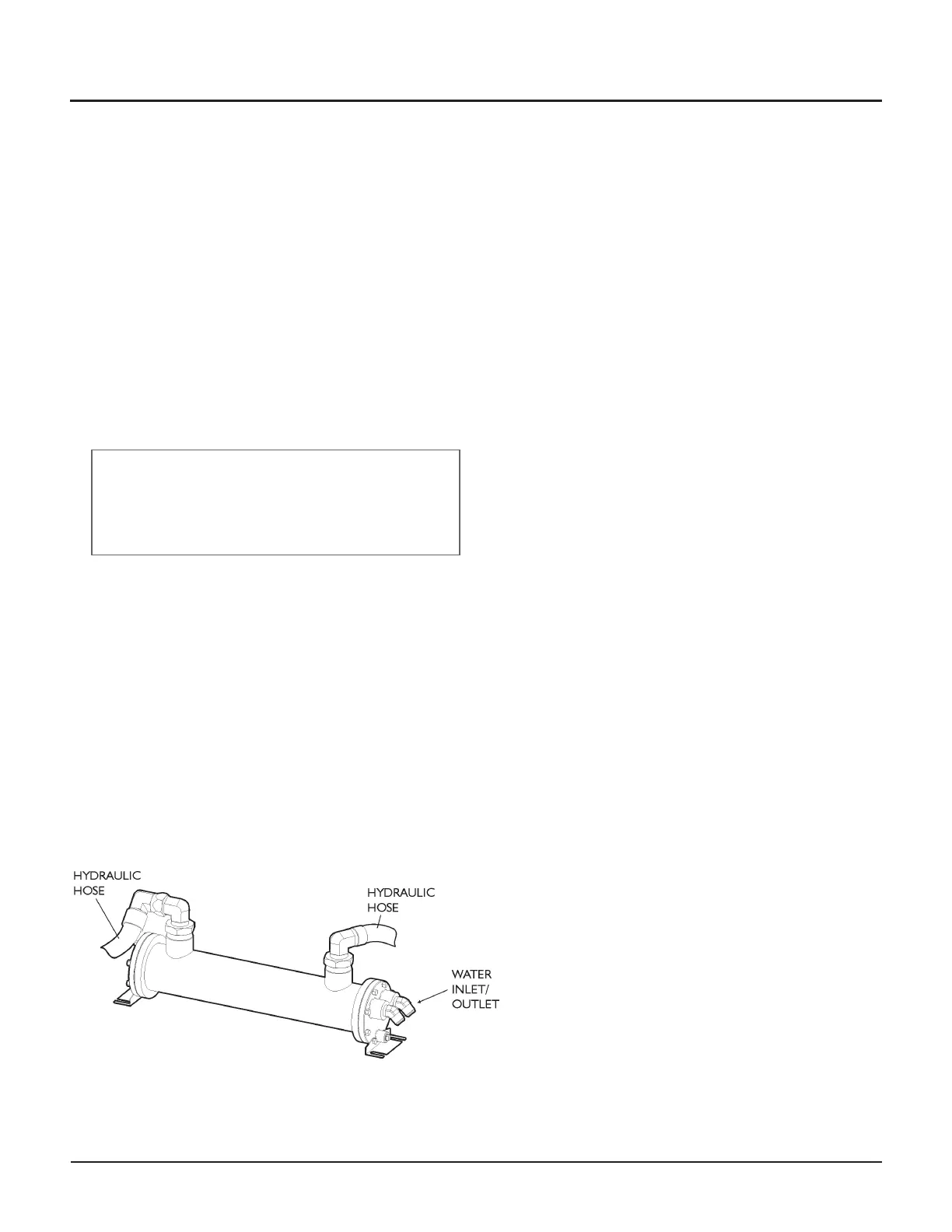

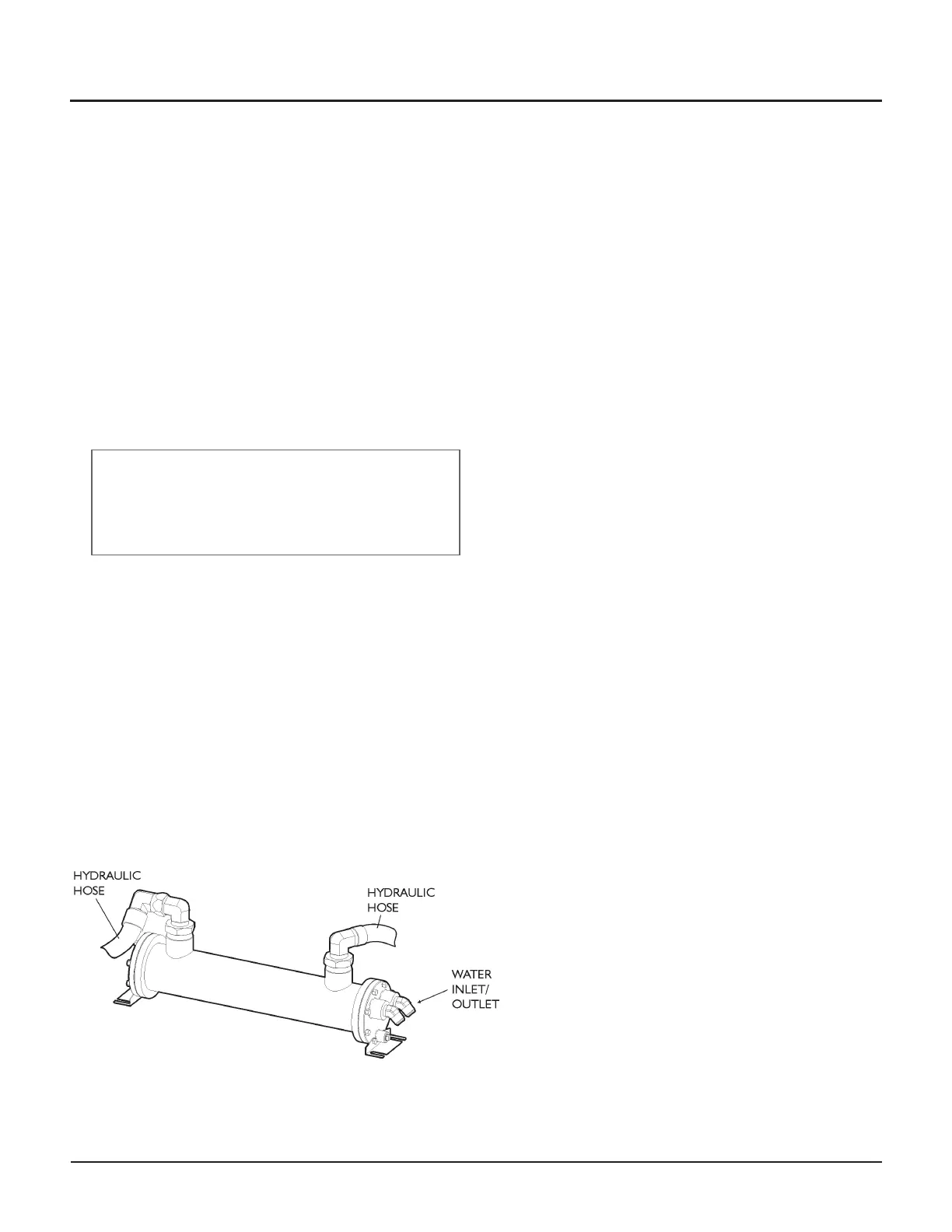

3. Disconnect the water hoses from the heat

exchanger.

4. Disconnect and plug the hydraulic oil lines. Hold the

heat exchanger level, and use a drip pan and rags to

catch dripping oil.

5. Remove the bolts that hold the heat exchanger to

the support and move the heat exchanger to a work

-

bench.

6. Plug one of the water ports and insert an air line fit

-

ting into the other.

7. Top off the oil level in the heat exchanger.

8. Connect an air line to the fitting. The air line must

be regulated to a maximum of 150 psig (10.3 bar)

air pressure, and have an on/off valve within easy

reach.

9. Watch the oil ports for air bubbles while slowly

opening the air valve and pressurizing the heat

exchanger. If the heat exchanger is leaking, you'll see

bubbles within a few seconds.

•

If the heat exchanger is defective, repair or re-

place it.

•

If the heat exchanger is OK, remove the fittings

and reinstall the heat exchanger.

•

Repeat Steps 3 through 9 for the second heat

exchanger.

•

If the heat exchanger is OK, water in the oil

was probably caused by putting contaminated

oil into the reservoir, excessive condensation in

the reservoir, or a missing reservoir filler cap.

See Checking the hydraulic oil.

10. Fill the hydraulic oil reservoir until oil is visible in the

sight gauge (see Chapter 1 for a list of recommended

oils).

CAUTION

You must add oil to the reservoir

AND

hydraulic pump case before operating the

pump or you will SEVERELY damage the system.

52 | M-390 © Flow International Corporation

HYPERJET™ 94i-S AND 94i-D PUMPS

Loading...

Loading...