•

Replacement wires must conform to the manufac

-

turer’s specifications, including proper color coding

and wire numbers.

Mechanical

•

Use only high-pressure fittings, valves, and tubing

certified for 92,000 psi (6483 bar) when making

changes to the high-pressure water system.

•

Immediately repair any leaks in fittings or connec

-

tions. Torque all fittings to the manufacturer’s specifi

-

cations.

•

When pressurizing any new, rebuilt, or recently ser

-

viced high-pressure component, clear all personnel

from the immediate area until system pressure has

been applied for three minutes and cycled on and

off at least three times. Increase pressure slowly, a

maximum of 20,000 psi/min (1380 bar/min).

•

Do not touch high-pressure leaks.

•

Bleed down system pressure before servicing any

part of the system. Never tighten pressurized fittings.

•

Follow the manufacturer’s recommendations for

servicing the equipment, and use only original

manufacturer replacement parts.

• Inspect the entire system before operating it. Correct

any fault or malfunction.

Tools

•

Use only approved test equipment, and check it

regularly for correct operation and calibration.

•

Use the correct tools—the incorrect tool can result in

injury to personnel or costly damage to the equipment.

•

Clear all tools and rags from around the machine

after service and before starting the equipment.

•

Use only approved work platforms. Never climb on

or around the equipment using makeshift devices.

Protective clothing

•

Do not wear loose clothing while working around

rotating parts of machinery.

•

Pressurized air can drive particles into eyes and skin

if handled improperly. To prevent injury, use appro-

priate protective equipment and clothing and exercise

extreme caution.

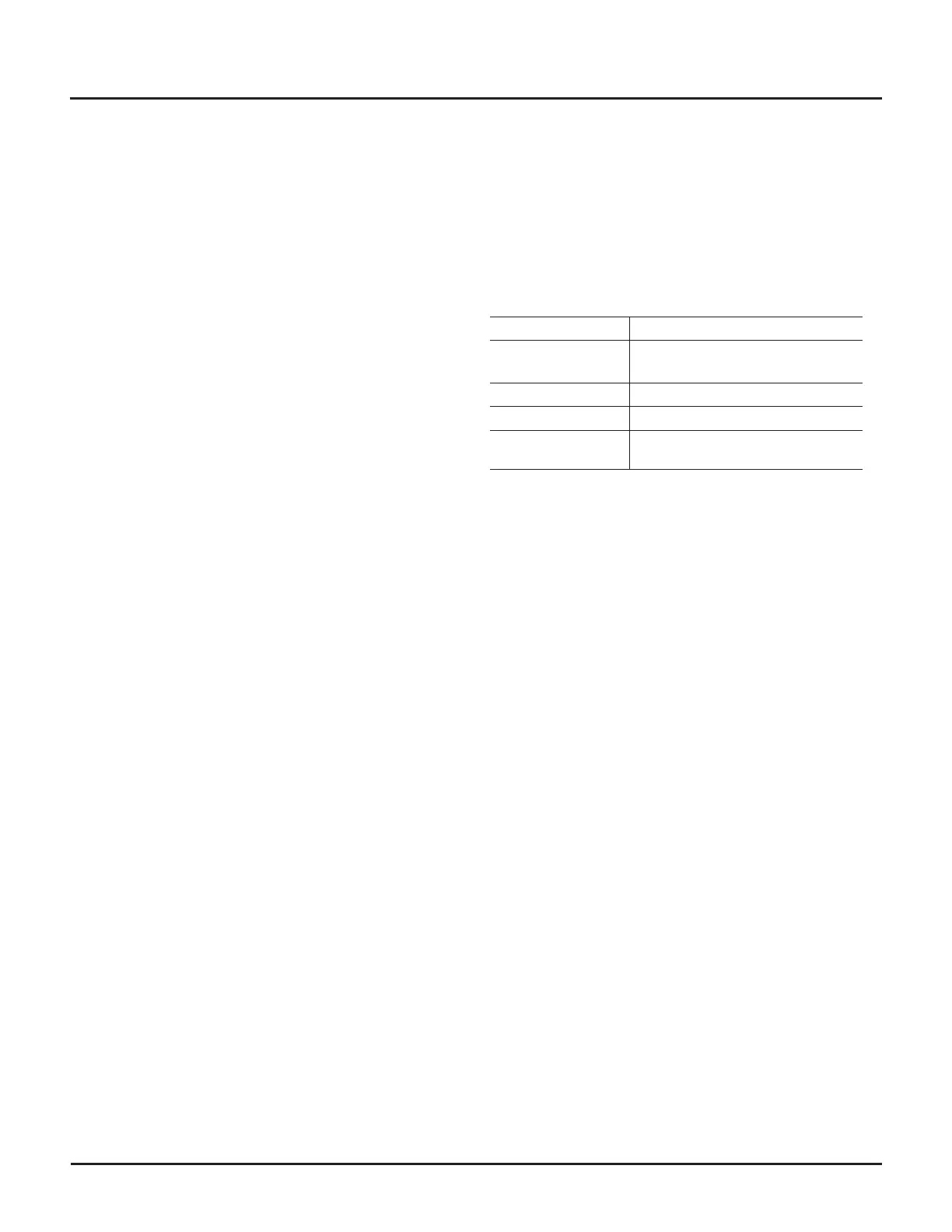

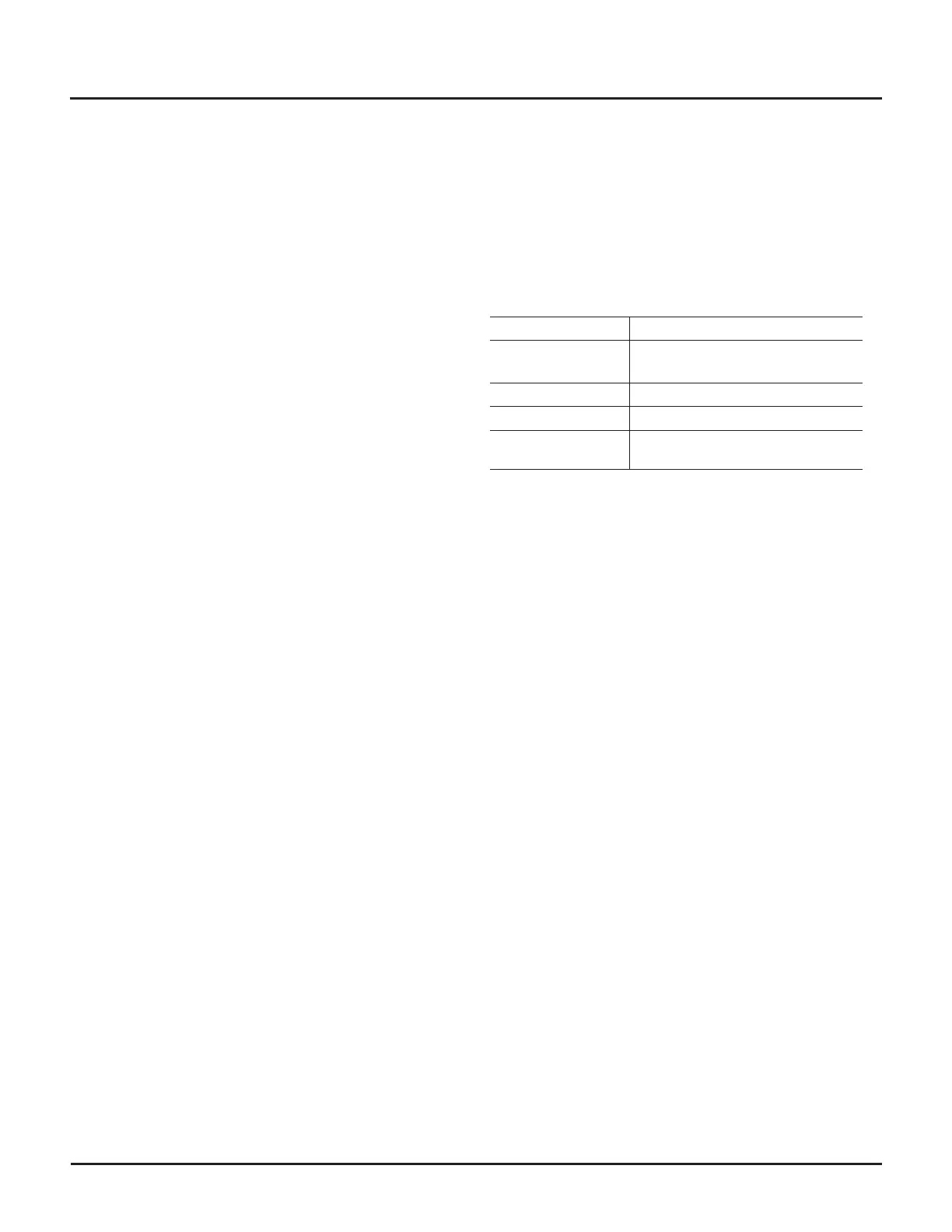

Hydraulic oil

Use an oil that does not contain anti-wear additives; the

following oils are recommended, but other manufacturer's

equivalents can be used:

•

Mobil DTE Medium

•

Shell Turbo T 46

•

Chevron Turbine Oil GST 46

•

Texaco Regal R&O 46

Kinematic viscosity 240 SSU @ 100°F (38°C)

Reservoir capacity HyperJet 94i-S: 25 gal (95 L)

HyperJet 94i-D: 37 gal (140 L)

Filtration 6 microns, continuous flow

Cooling Oil-to-water heat exchanger

Optimum oil temper

-

ature

105°F (40.5°C)

32 | M-390 © Flow International Corporation

HYPERJET™ 94i-S AND 94i-D PUMPS

Loading...

Loading...