Changing the hydraulic oil

This is the accepted procedure for changing hydraulic

oil. Your oil supplier can tell you how to properly dis

-

pose of used hydraulic oil.

Service steps

WARNING

Place the main electrical disconnect in the OFF

position and bleed down all high-pressure lines.

Place an Out of Service tag on the main electrical

disconnect and lock it out. Failure to do so can result

in equipment damage or injury to personnel.

1. Shut down the system.

2. Use a hose to drain the oil from the reservoir drain

valve into a container large enough to hold 37 gal

(140 L).

3. Remove the access cover from the reservoir and

thoroughly wipe clean the inside surfaces of the res

-

ervoir.

•

If the oil was contaminated with metal particles

because of a pump or hydraulic piston failure,

see Cleaning a contaminated oil system.

CAUTION

You must thoroughly clean the reservoir after metal

flakes have been pumped through it or the pump,

intensifier, shift valve, pilot valve, shift cables,

pressure control valves, and other components can

fail. Your warranty does not cover this damage.

4. Change the hydraulic oil filter. See Replacing the

hydraulic oil filter.

© Flow International Corporation M-390 | 49

CHAPTER 5

Servicing the Pump

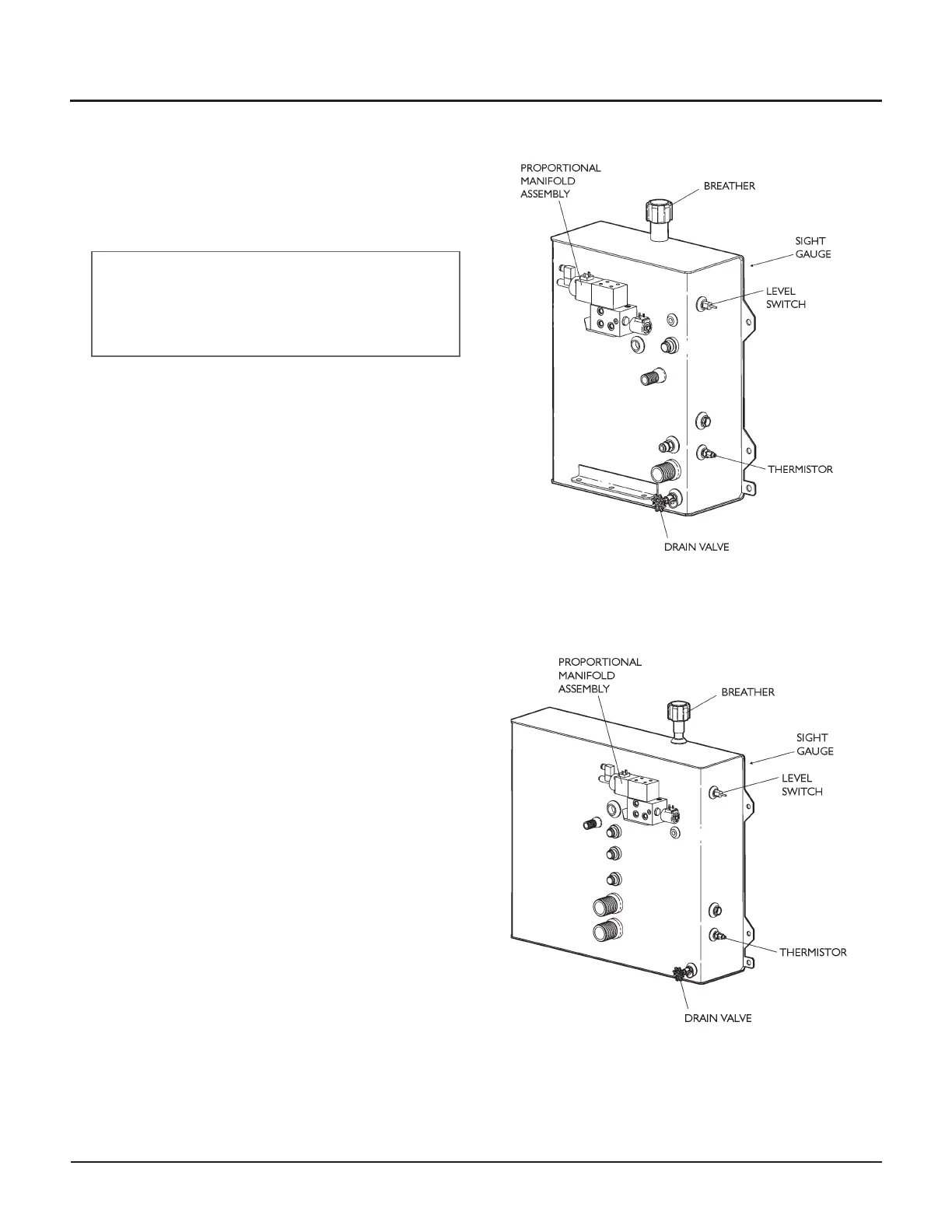

HyperJet 94i-D reservoir

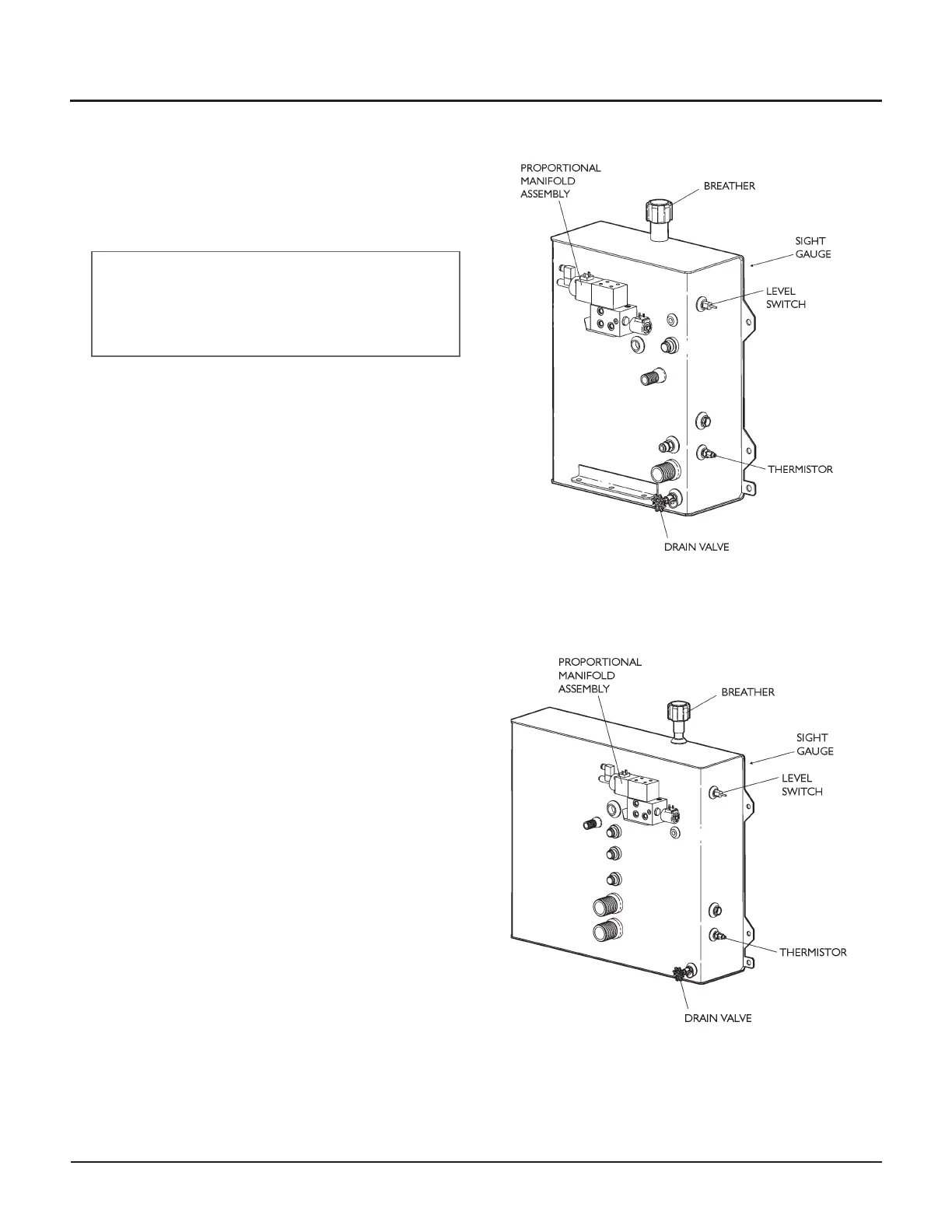

HyperJet 94i-S reservoir

Loading...

Loading...