Protective clothing

Personnel operating hand-held, high-pressure water cut

-

ting or cleaning equipment and those working nearby

should wear the protective clothing and safety devices

described in this chapter.

FLOW recommends that work-site safety personnel ap

-

prove all safety equipment and clothing for everyone

working around waterjet equipment.

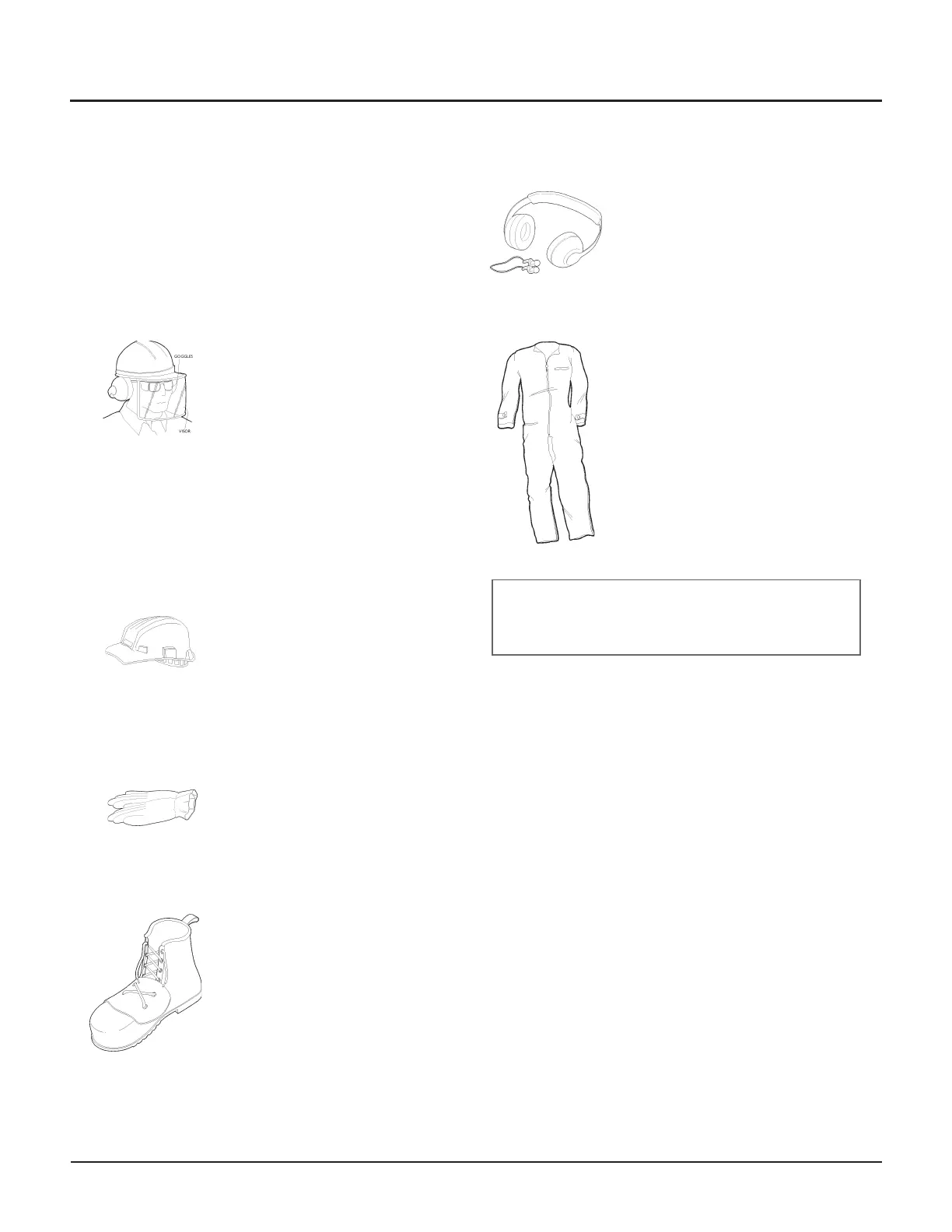

Eye protection

•

At a minimum, operators must

wear safety glasses with side

shields and a visor, or goggles and

a visor, to guard against spray and

flying debris.

•

All eye protection shall meet ap

-

propriate ANSI requirements for

that type of eye protection.

•

Some states and countries have

their own eye protection rules

that must be followed.

Head protection

•

Helmets must be worn at all

times by all personnel within the

work area.

•

Helmet material must withstand

mechanical shock to 10 G in 8 ms

without fracturing.

Hand protection

•

The operator must wear gloves

at all times. Leather gloves are

preferred.

Foot protection

•

Safety footwear with steel

toe-caps 0.02-in. (5 mm) thick

(minimum) must be worn. The

toe cap must cover at least 30%

of the footwear length.

•

For some applications, footwear

must be equipped with metatar

-

sal guards to provide instep pro

-

tection.

Hearing protection

•

Operators and other personnel

exposed to noise levels of more

than 90 dBa for more than

1 hour must wear suitable ear

protection. Ear plugs and muffs

are usually adequate.

Body protection

•

Waterproof garments only protect

the operator from spray and flying

debris. They

DO NOT provide any

protection from direct jet impact.

WARNING

NEVER point a waterjet cutting or cleaning tool

at yourself or at any person. Do not aim any

waterjet tool at anything you do not want to cut.

18 | M-390 © Flow International Corporation

HYPERJET™ 94i-S AND 94i-D PUMPS

Loading...

Loading...