Replacing the kidney loop oil filter

Replace the hydraulic oil filter:

•

if the restriction indicator has actuated

•

after a specific number of operating hours

•

after a specific length of time

•

when you change the hydraulic oil

Service steps

WARNING

Place the main electrical disconnect in the OFF

position and bleed down all high-pressure lines.

Place an Out of Service tag on the main electrical

disconnect and lock it out. Failure to do so can result in

equipment damage or injury to personnel.

1. Shut down the system.

2. Locate the oil filter housing within the pump frame.

3. Place a drip pan under the housing.

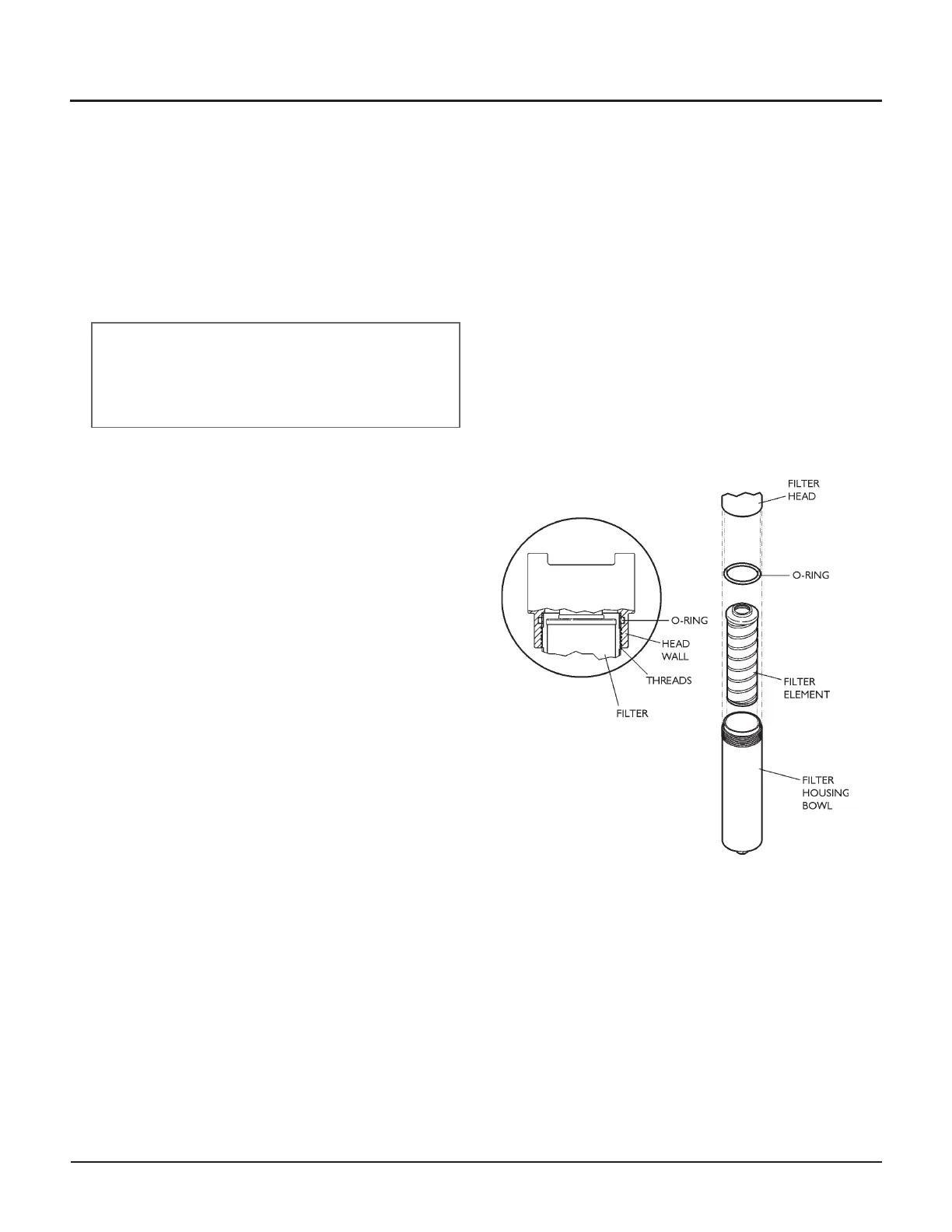

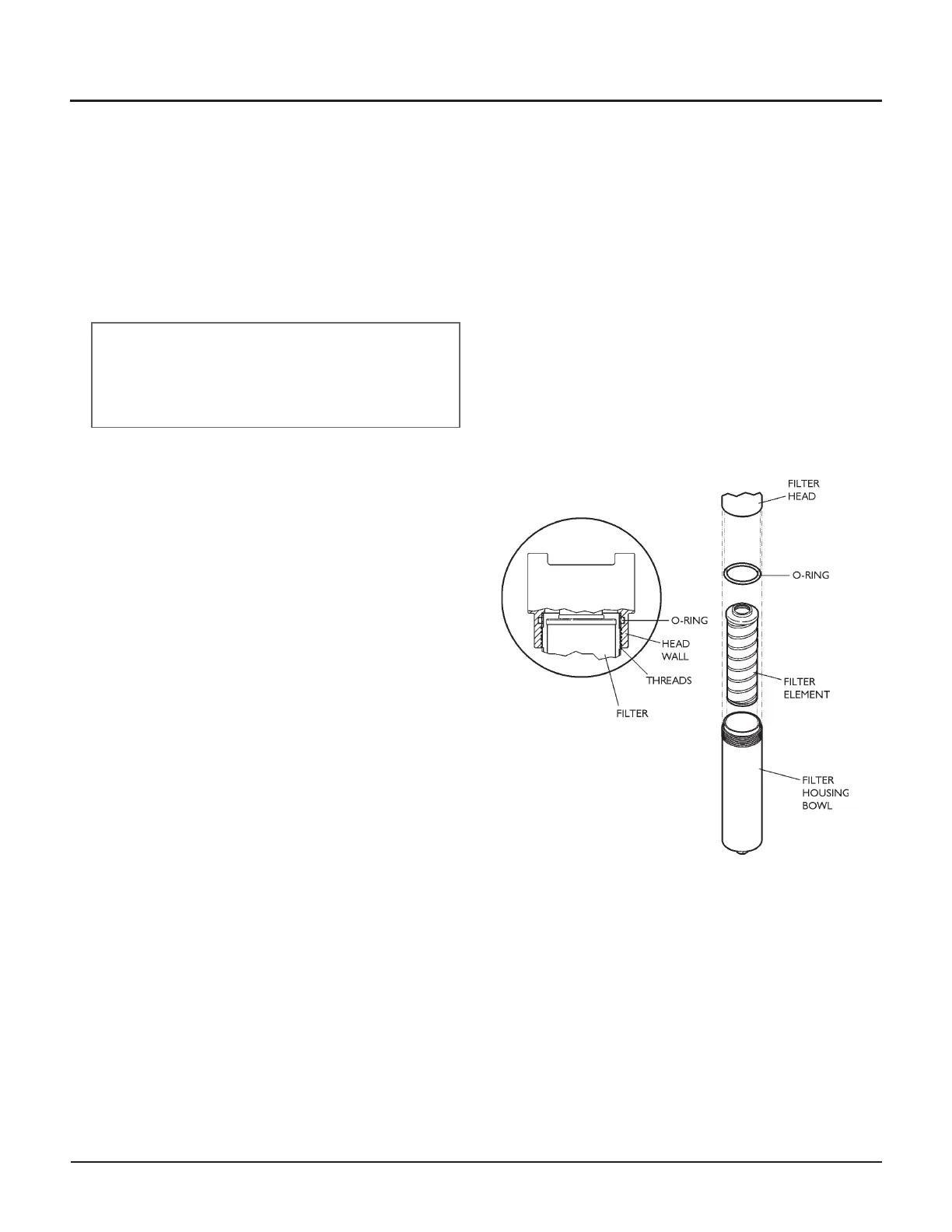

4. Unscrew the filter bowl from the filter head. Drain

the oil from the bowl into the drip pan.

5. Gently pull and turn the filter element to remove it

from the housing head, and place it in a drip pan.

Inspect the element and bowl for visible dirt or

particles—this can give early warning of component

failure.

6. Clean out the bowl and the filter housing and insert

a new element.

7. Lubricate the new element o-ring with clean hydrau

-

lic oil and install in the housing head.

8. Raise the bowl into position to engage the threads.

Thread the bowl into the filter head until it is firmly

seated.

9. Operate the pump for 3–5 minutes at the maximum

rated pressure. Check for leaks.

When all work is satisfactory, remove tools, parts, and

rags from the pump and close the cover. Remove the

Out of Service tag from the main electrical disconnect.

© Flow International Corporation M-390 | 51

CHAPTER 5

Servicing the Pump

Loading...

Loading...