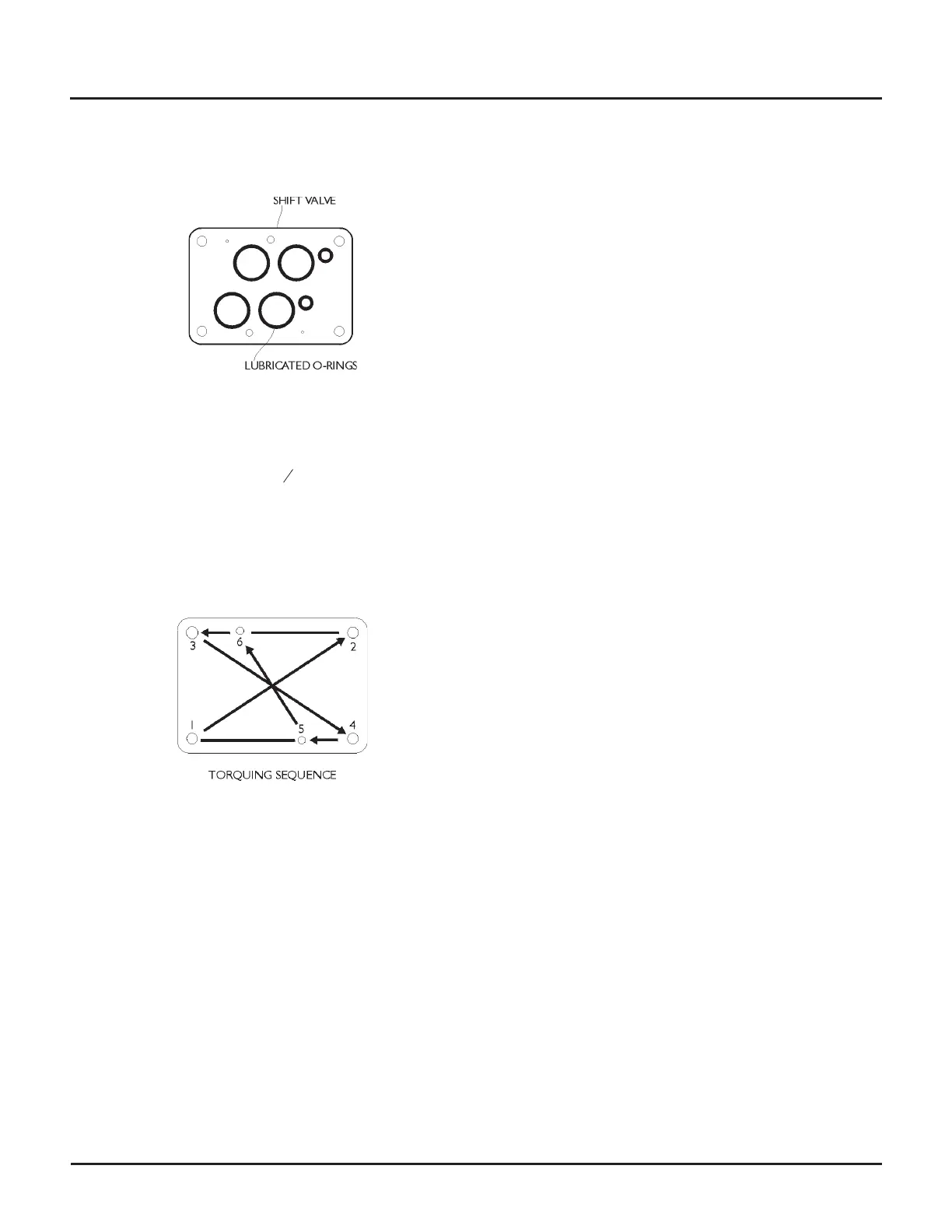

7. Inspect the o-rings for wear and replace as

necessary. Lubricate the o-rings with Parker Super O

Ring Lube and insert them in the shift valve.

8. Place the shift valve body on the manifold so that

the offset ports in the shift valve match those in the

manifold. Thread in the cap screws.

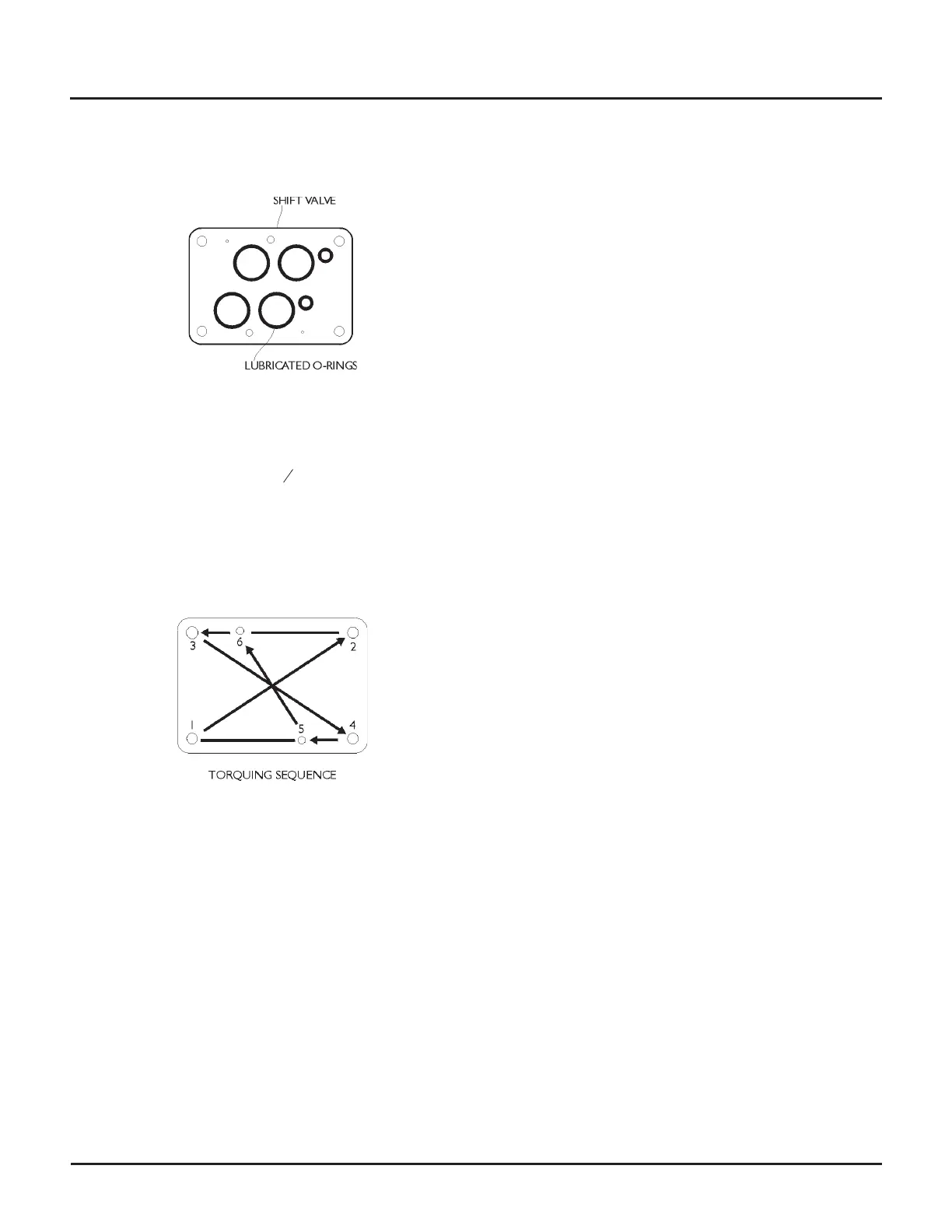

9. Torque the cap screws in

1

8

-turn increments in this

two step process:

a. Torque all cap screws (in the order 1 to 6, as

shown) to 11.5 ft-lb (15.6 N-m).

b. Torque the outer cap screws (in the order 1 to 4,

as shown) to 55 ft-lb (74.5 N-m).

10. Use your fingers to make sure the spool moves

freely.

11. Lubricate the end cap o-rings with Parker Super O

Ring Lube and install in the end caps. Install the end

caps on the shift valve body. Torque the cap screws

to 30 ft-lb (40.7 N-m).

12. Install the pilot valve (see Pilot valve).

Note: If the reservoir was drained in Step 1, refill

the reservoir.

13. Remove the Out of Service tags from the main elec

-

trical disconnects.

Note: This service procedure introduces a small

amount of air into the hydraulic system, which will

purge automatically on pump unit start-up.

14. Run the pump unit at low pressure for 3–5 minutes

while checking for leaks. Remove tools, parts and

rags from the pump unit.

The pump unit is ready for operation.

© Flow International Corporation M-390 | 65

CHAPTER 5

Servicing the Pump

Loading...

Loading...