Logix

®

3200MD+ Digital Positioners FCD LGENIM0110-0 05/16

flowserve.com 17

9 Connect regulated air supply to appropriate port in

manifold. See section 19 TUBING.

10 Connect the power to the 4-20 mA terminals. See

section 20 ELECTRICAL CONNECTIONS.

11 Remove main cover and locate DIP switches and

QUICK-CAL/ACCEPT button.

12 Refer to sticker on main board cover and set DIP

switches accordingly. See section 21 STARTUP.

13 Press the QUICK-CAL/ACCEPT button for three to

four seconds or until the positioner begins to move.

The positioner will now perform a stroke calibration.

14 If the calibration was successful the green LED will

blink GGGG or GGGY and the valve will be in control

mode.

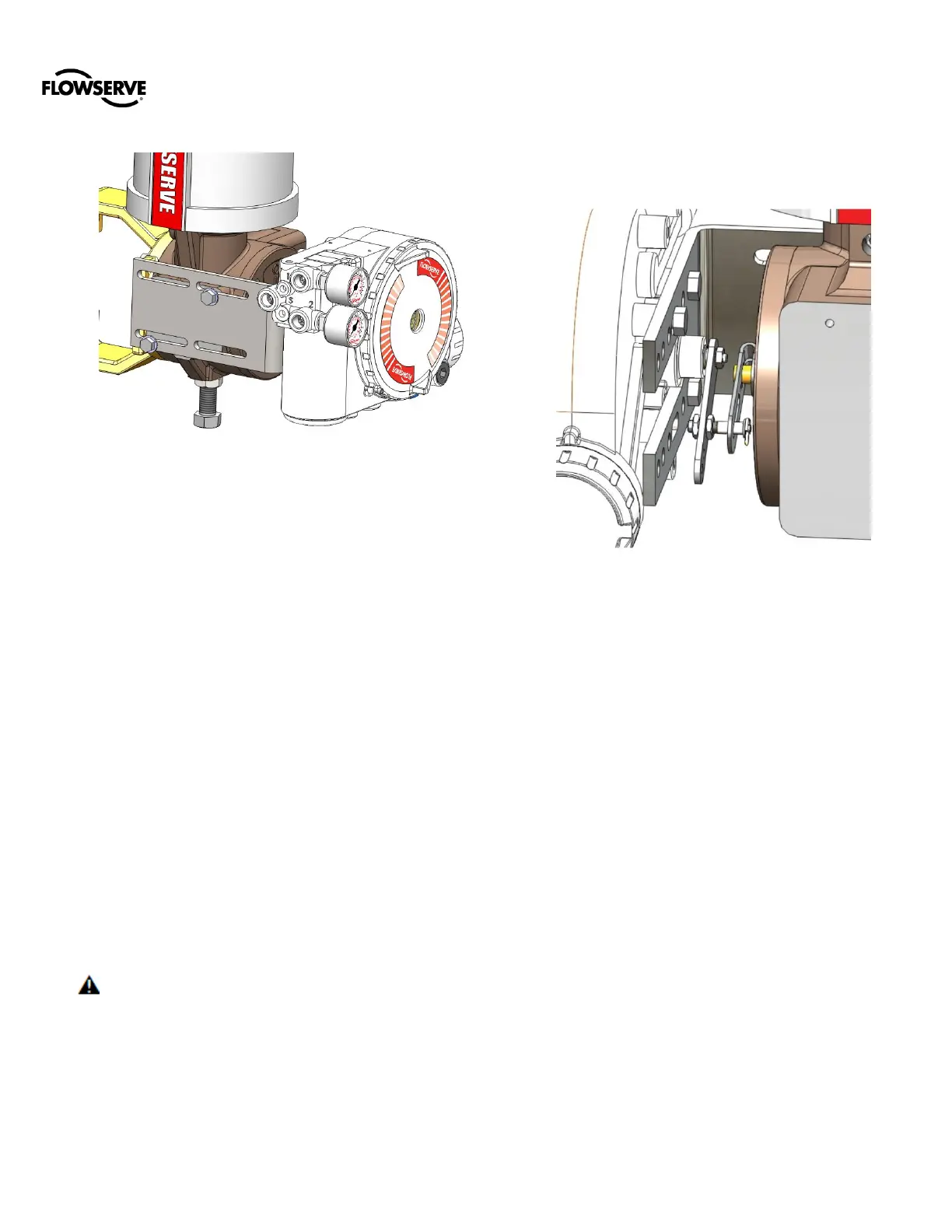

15 If calibration fails, as indicated by a RGGY blink code,

retry the calibration. If it still fails, the feedback values

were exceeded and the arm must be adjusted away

from the positioner’s limits. Rotate the feedback shaft

so that the full free travel of the feedback shaft is in

the range of the actuator movement. Optionally,

continue to attempt the calibration. Each calibration

attempt adjusts the acceptable limits and it should

pass eventually.

CAUTION: Remember to remove the air supply before

re-adjusting take-off arm.

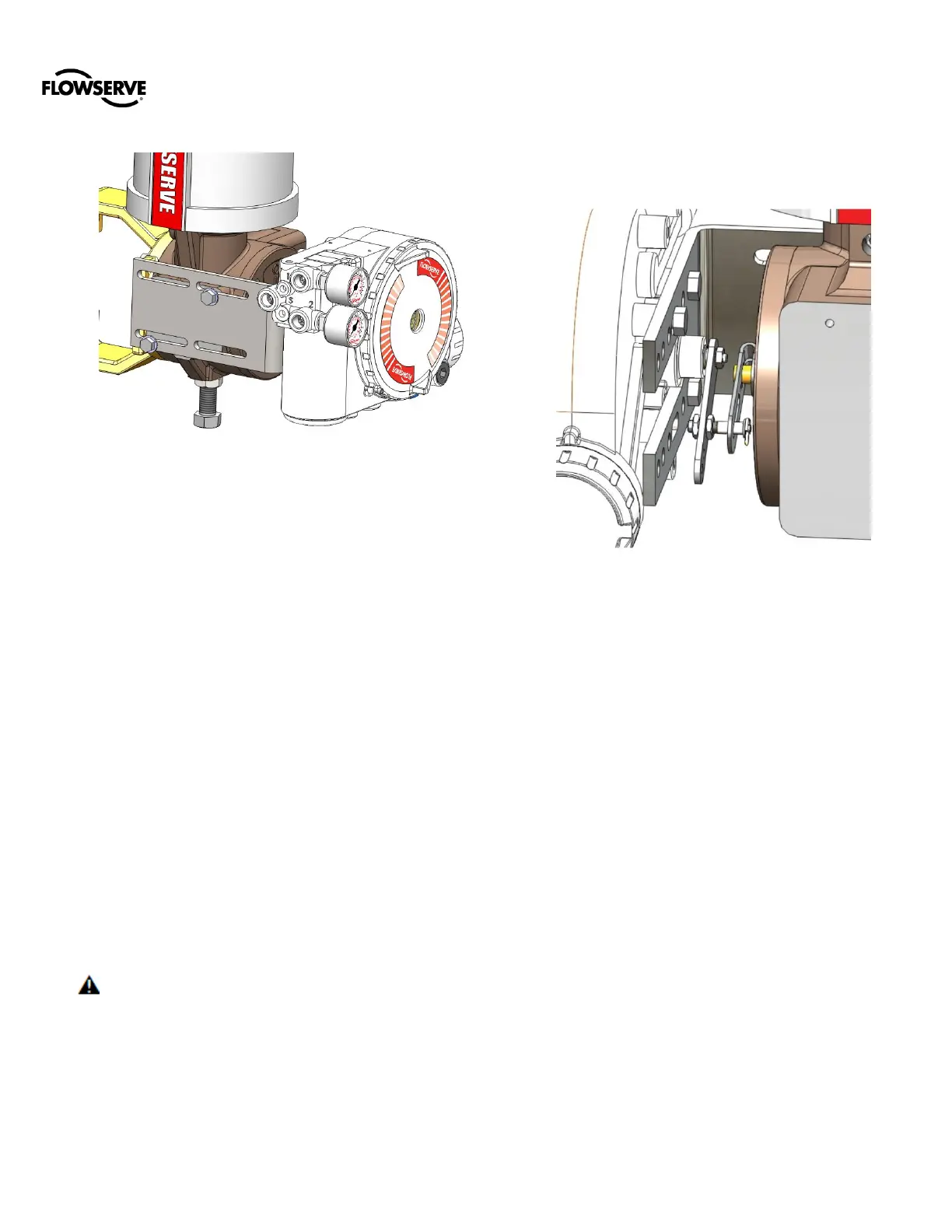

NOTE: If mounted properly, the follower arm should be

horizontal when the valve is at 50% stroke and should

move approximately ±30° from horizontal over the full

stroke of the valve.

NOTE: To virtually eliminate non-linearity, use the

Linearization feature on the Custom Characterization page

of the DTM.

Loading...

Loading...