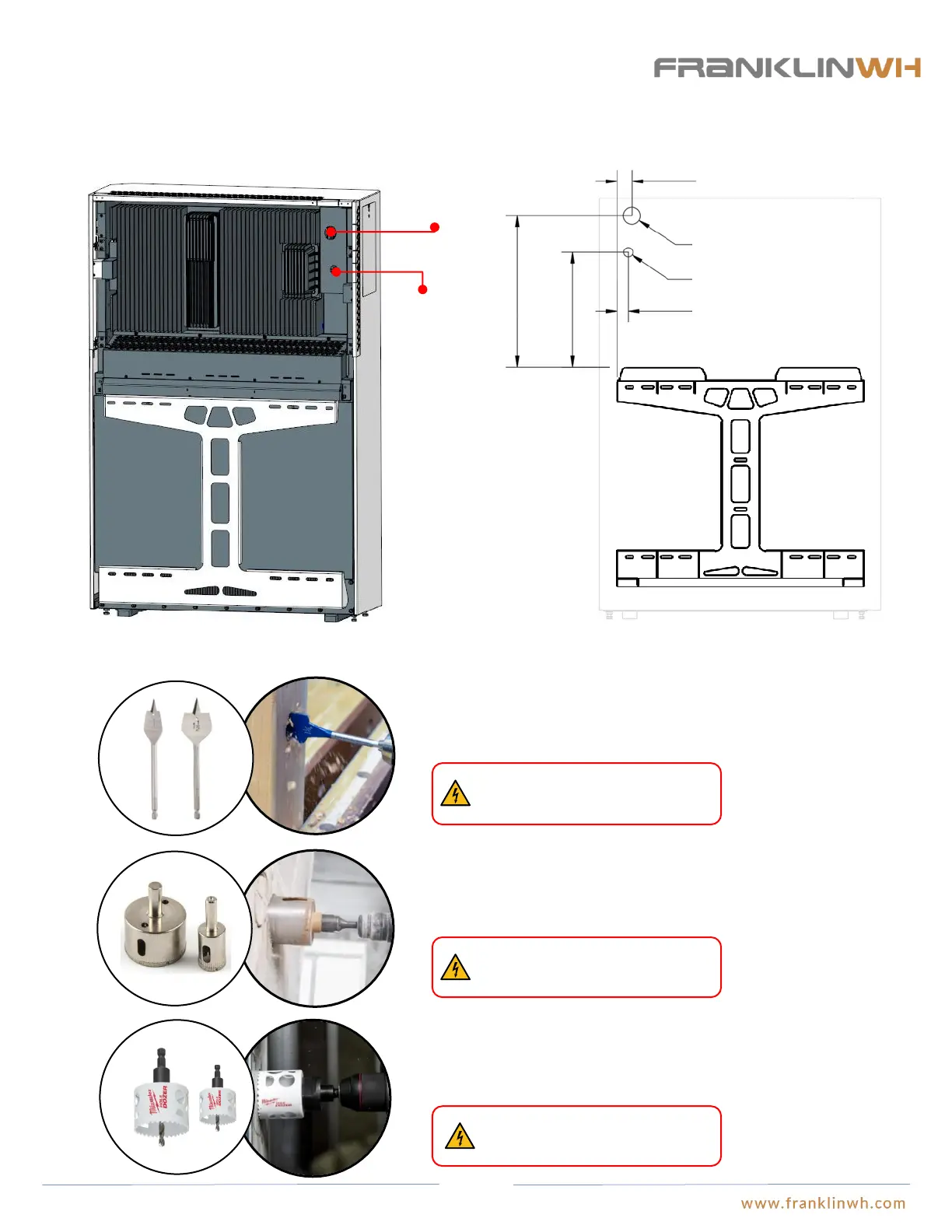

Step 3: aPower

● Drill holes at the cable inlet on the back of aPower (this step is not necessary if cables do not enter aPower from inside the wall or

through the wall). Coordinate the holes with the any present external metal or wooden support brackets..

AC cable

Reserved position

for conduits

Communicati

on cable

Reserved

position for

conduits

Back view: Mounting brackets, positions of holes for electric conduits Front view: Mounting brackets, positions of holes for electric conduits

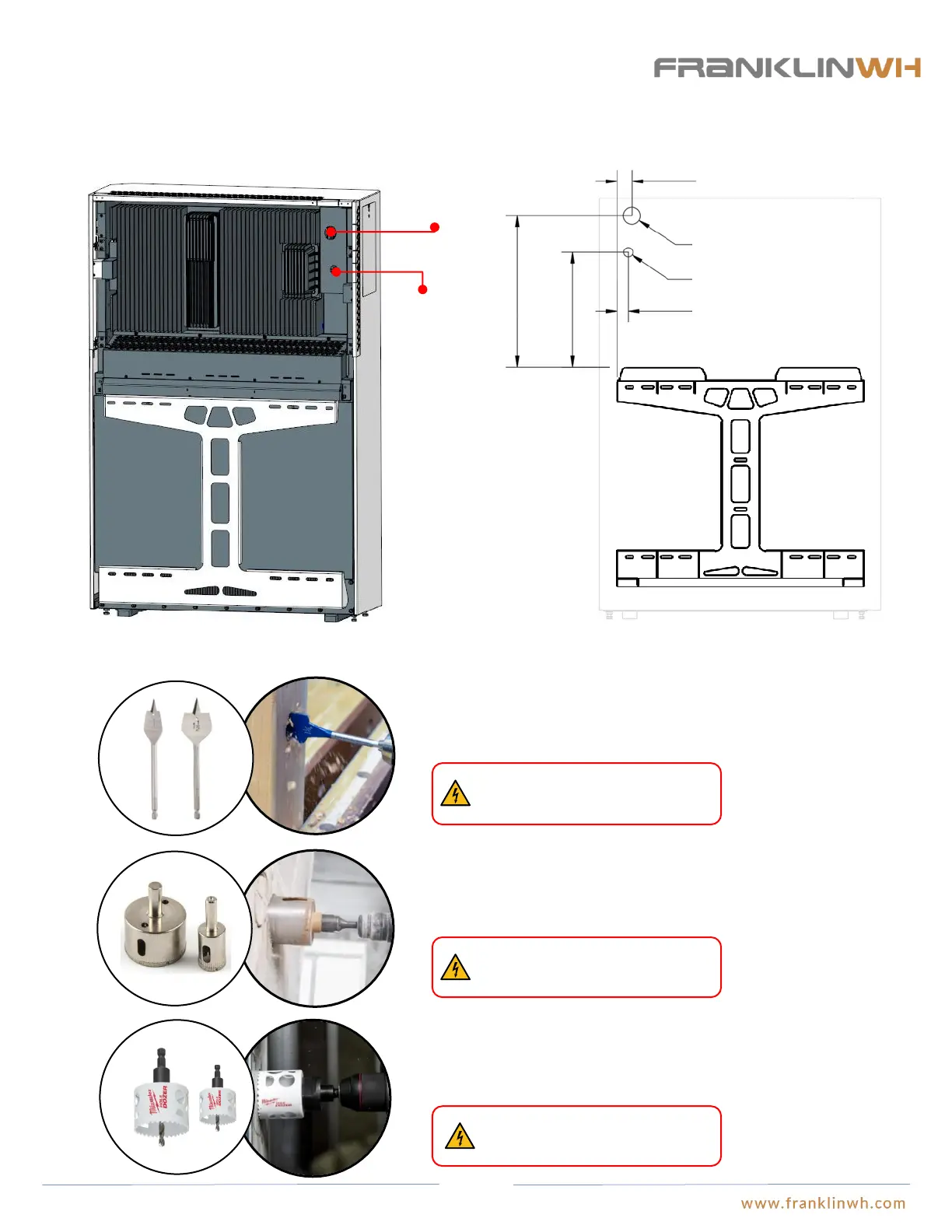

In case of wooden wall:

Electric drill and 1”,1-1/2” wood bits are recommended to create holes

for running cables on wooden walls. It is important that the drill bit

should be kept 90° perpendicular to the wall when drilling.

In case of concrete or brick walls:

Hammer drill and 1”, 1-1/2” Diamond tipped core bits are recommended

to create holes for running cables on concrete walls or brick walls. Wet

the wall and HEPA vacuum the dust, to protect the drill bits from

overheating. Keep the drill bit 90° perpendicular to the wall surface.

In case of metal wall or metallic studs:

Electric drill and 1”, 1-1/2” hole saw are recommended to create holes

for running cables on metal plate and hardware. Wet the wall and use a

HEPA vacuum to manage dust to protect the drill bits from overheating.

Keep the drill bit 90° perpendicular to the wall surface.

EPQ must be used in the above-

mentioned operation.

EPQ must be used in the above-

mentioned operation.

EPQ must be used in the above-

mentioned operation.

Drill cable inlet holes on the wall (applies only when connecting cables run in wall, not exterior conduit)

16.25 in

1-1/4ӯ

3/4 in Ø

12.5 in

1-1/2”

50 mm (2.0 in)

27

Loading...

Loading...