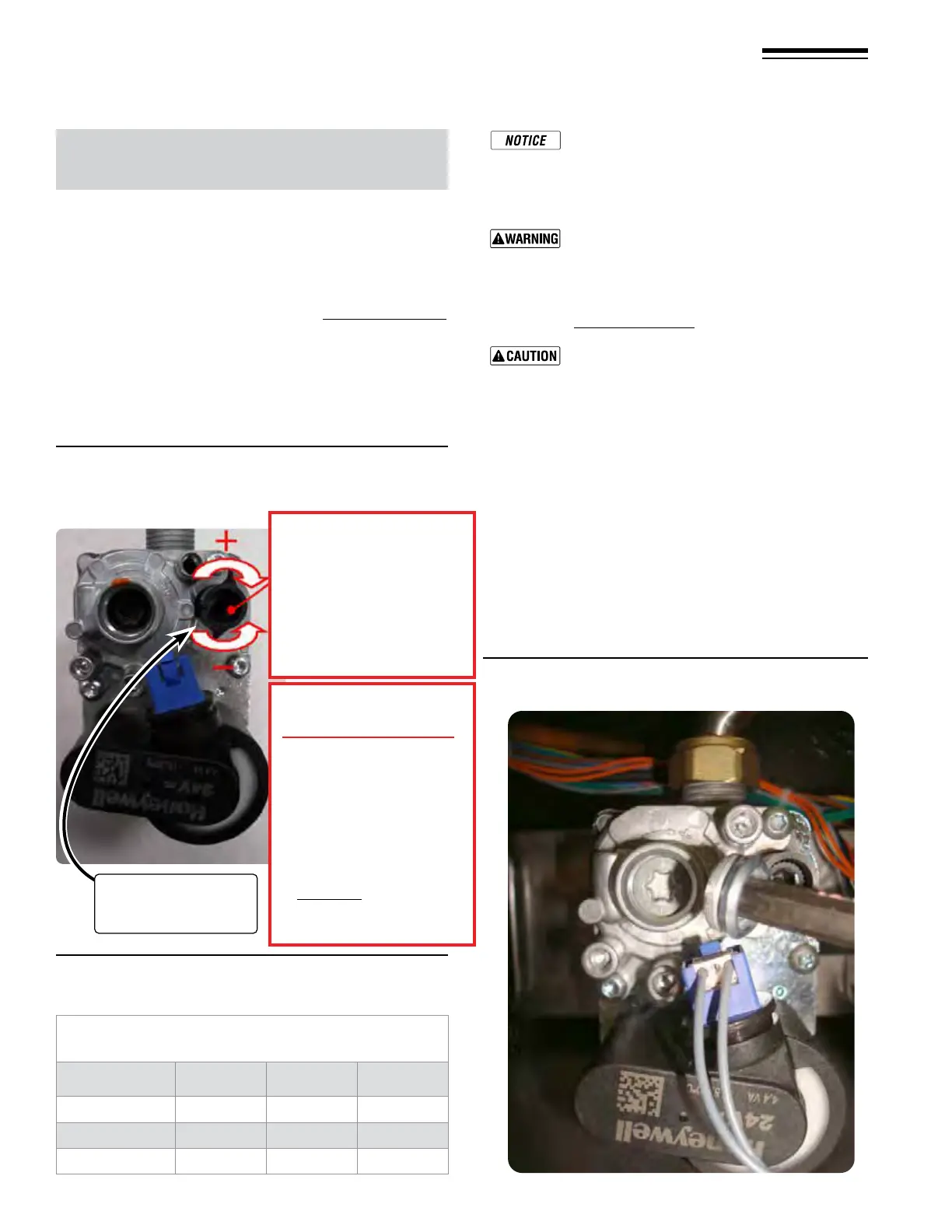

Figure 106 Throttle adjustment screw ––

(ONLY for use by a qualied technician, using

calibrated combustion test instruments).

Part number 550-142-950/0122

82

FreeStyle

®

series

2

wall mount gas-fired water boiler – boiler manual

33 Startup — nal checks (continued)

Figure 107 Maximum rate combustion values –

measured values must be within the ranges

given below

Using a combustion analyzer check the CO

2

values at low and high re. It should be within

values from the table in Figure107. e dier-

ence of CO

2

from high re to low re should

NEVER be below 0.2% or above 1%.

DO NOT attempt to adjust the throttle screw

unless by a qualied technician, and with the

use of calibrated combustion test instruments.

Adjust the throttle screw only as needed to meet

the combustion values given in Figure107 and

Figure110,page83.

Adjust in steps of no more than 1/8 of a turn and

wait 1 minute aer each adjustment to allow the

setting to stabilise. Turning the screw too far will

cause the adjustment to reverse behavior.

4. In the event that the CO

2

setting level with an acceptable

CO/CO

2

ratio cannot be obtained please contact your

Williamson-ermoo representative.

5. Should you require any assistance during the set up pro-

cedure contact your Williamson-ermoo representative

if the problem cannot be addressed with the information

provided in this manual.

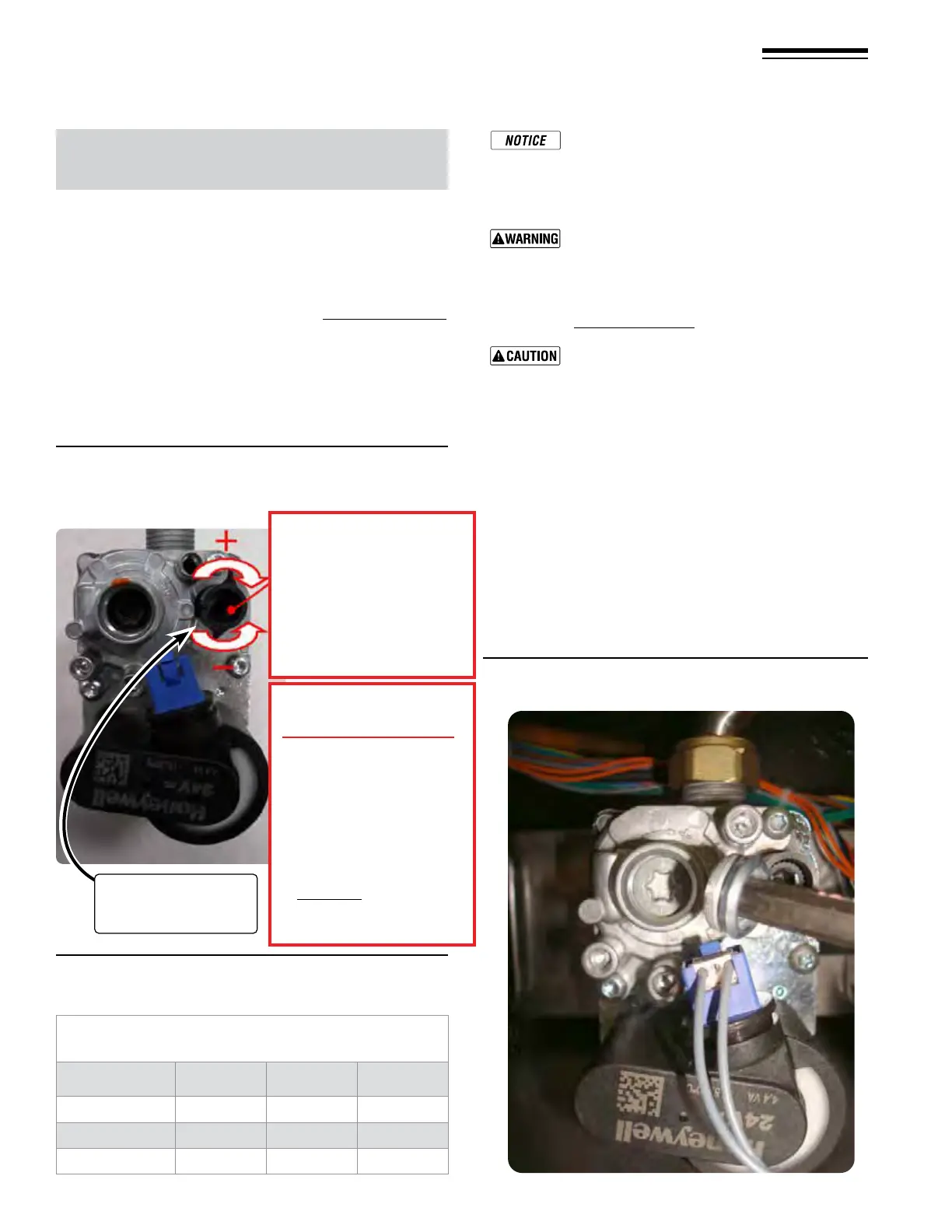

6. Remove T-40 cap, see Figure108, below, for Oset screw

adjustment.

Natural Gas/LP Acceptable Combustion Range

Maximum Rate after 10 minutes from cold

Boiler Model CO/(PPM) CO

2

NG % CO

2

LP %

FS-80

110 9.0

–

9.5 10.2

–

10.7

FS-120

110 9.0

–

9.5 10.2

–

10.7

FS-155

120 9.0

–

9.5 10.2

–

10.7

Setting the Air/Gas Ratio valve

ere are two adjustments possible on the air/gas ratio valve,

the throttle setting at Maximum rate and the oset setting at

Minimum rate. If either setting is adjusted the combustion values

must be rechecked at both rates.

At Maximum Rate:

1. Adjust the boiler to maximum rate in Figure104,page79,

Test Mode.

2. Wait 10 minutes to allow the boiler to stabilize.

3. Now adjust the rottle setting (Figure106 - screw A) until

the CO

2

is at the correct SETTING LEVEL (see Figure107),

below conrm that the CO/CO

2

ratio is within limits (clock-

wise to increase gas).

Figure 108 Remove

T-40 cover cap with supplied Torx

wrench for adjustment

Throttle adjustment

screw

A

CO

2

Max. Regulating screw

Test at Max Power 100%

Turn clockwise (open gas) for

“MAX gas ow”

Turn counter-clockwise

(close gas)

for “MIN gas ow”

Rough start point

For LP Start up ONLY

Adjust gas valve

HIGH FIRE

screw on right with

Allen wrench turn

Counter-Clock wise

1-1/8 turns.

Final Combustion values

MUST BE checked with

Combustion Analyzer.

Loading...

Loading...