66 PB

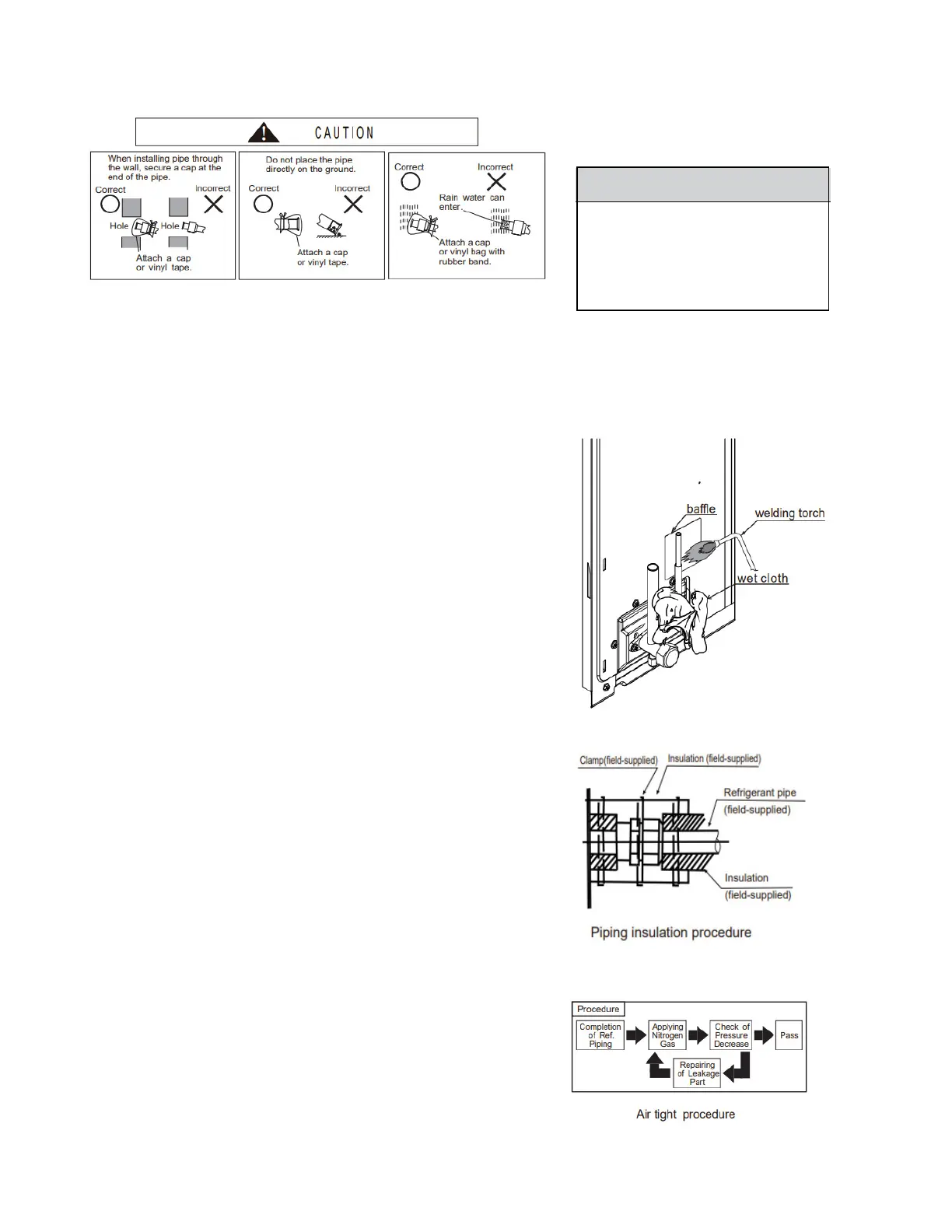

Precautions and steps during brazing service valve:

a. Remove the caps from both the liquid and gas service valve

service ports at the outdoor unit.

b. Braze the liquid piping and gas piping to the respective valve at

the outdoor unit.

Prior to brazing, wrap a wet cloth around each service valve to

prevent heat damage while brazing.

A fire plate or divider can be used to protect painted surfaces and

insulation while brazing.

c. Cool joints and other heat sensitive components with a wet rag

during brazing.

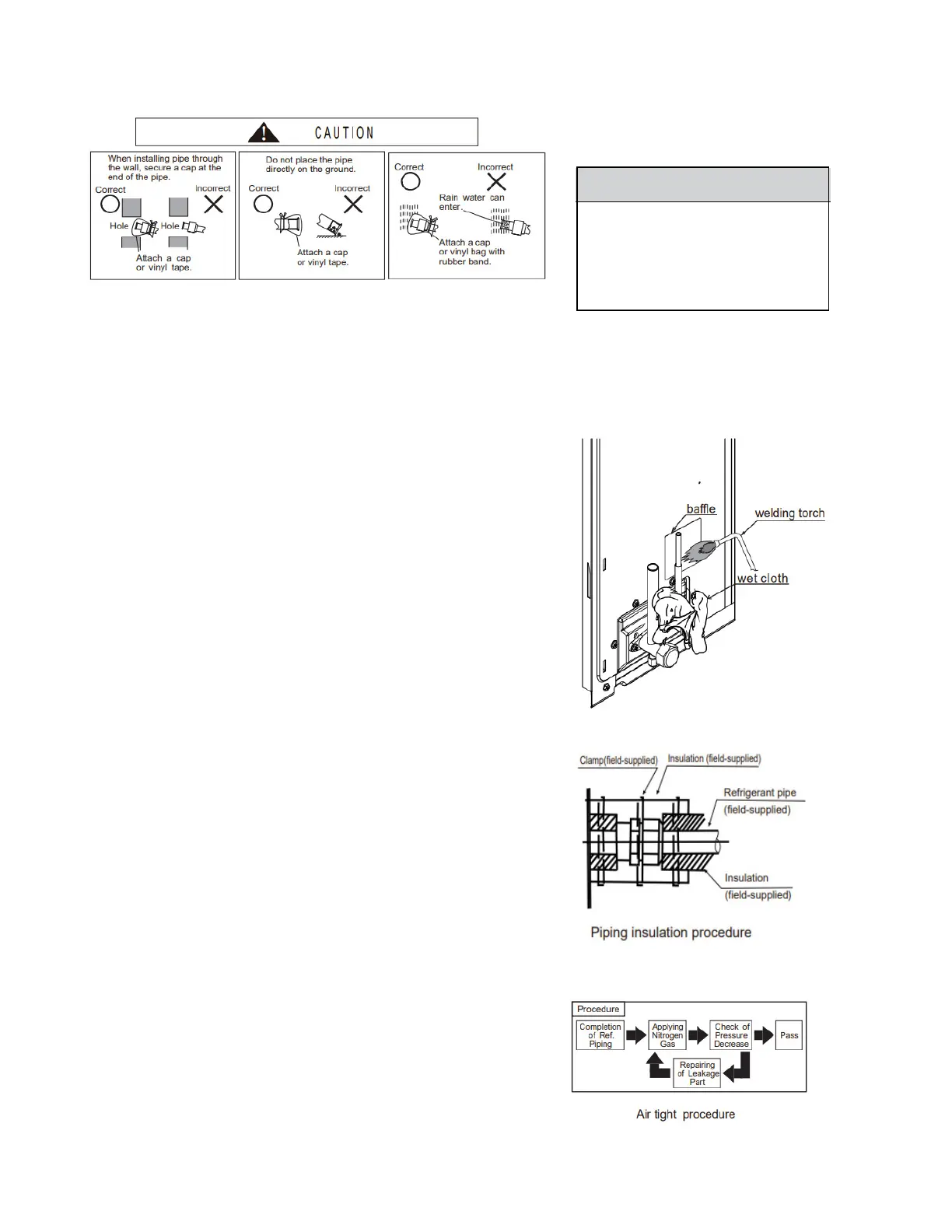

(3) After connecting the refrigerant pipes, insulate the pipes according

to local codes and temperature/humidity conditions. See also

detailed figure.

·For outdoor unit side, insulate all piping including valves.

·Cover piping joints with pipe cover.

·Using piping tape, apply taping starting from the entry of outdoor unit.

- Secure the end of the piping tape with adhesive tape.

- When piping has to be routed above ceiling, closet or area where

temperature and humidity are high, apply additional insulation

for prevention of condensation.

5. Air tight test

Use Nitrogen only.

Using charging hose, connect the gauge manifold at the nitrogen

cylinder to the check joints of the liquid line and the gas line stop-valves.

Perform the air-tight test.

Don't open the gas line stop valves.

Apply nitrogen gas pressure of 550 psig (3.8 MPa).

Check for any gas leaks at the flare nut connections, or brazed

parts utilizing gas leak detector or foaming agent.

In addition, observe the gas pressure during the leak test to make sure that it does not decrease.

After the air tight test, release nitrogen gas.

4

(1)

. Piping connection

(2)

Con

Conne

firm

ct t

tha

he

t

the

indoor

val

v

uni

es

t

are

and

c

t

lo

he

s

ed.

refrigerant pipes. The refrigerant pip it

pp

h

l

a

ie

d

phosphorous-copper alloy material s

ou

ing

uc

t

h

s

door

as

hould

S

uni

ilf

t

be

wi

os-15

th

bra

f

z

or

ield-s

ed

equ

w

u

ivalen t.

3

(1)

.

P

Refr

ipe

ig

cu

era

tt

nt

ing

-

piping work

Cut the copper pipe correctly with pipe cutter.

(2) Burrs removal-

Completely remove all

he c

burr

opper

s f

rom

pipe

the

cut

downward

cross

t

se

o

ct

pre

ion

ve*Position the end of t

o

n

t

b rr

p

s f

pe

ro

. f

t

h

u

e i

m dropping in the pipe.

INSTALLATION

Refrigerant Piping

NOTICE

A Bi -Flowliquid line drier is required

to be installed on the refrigerant

system during installation or any

refrigerant system repairs. Install in

between liquid line stop and TXV.

Loading...

Loading...