6-9

Ver.1.36

6.2 REGULAR MAINTENANCE

In addition to routine maintenance, regular maintenance every three to four months is recommended.

This will ensure trouble-free operation.

6.2.1 Pyrolyzer furnace

(1) Cooling fan

Check to see if the cooling fan starts spinning as soon as the temperature controller is on. If the

cooling fan does not start immediately, the fan needs to be replaced. The cooling fan maintains the the

sample temperature near room temperature when the system is at stand by. If the temperature of the

sample when in the standby position exceeds 100°C, a protection function is activated and the heater

power is turned off.

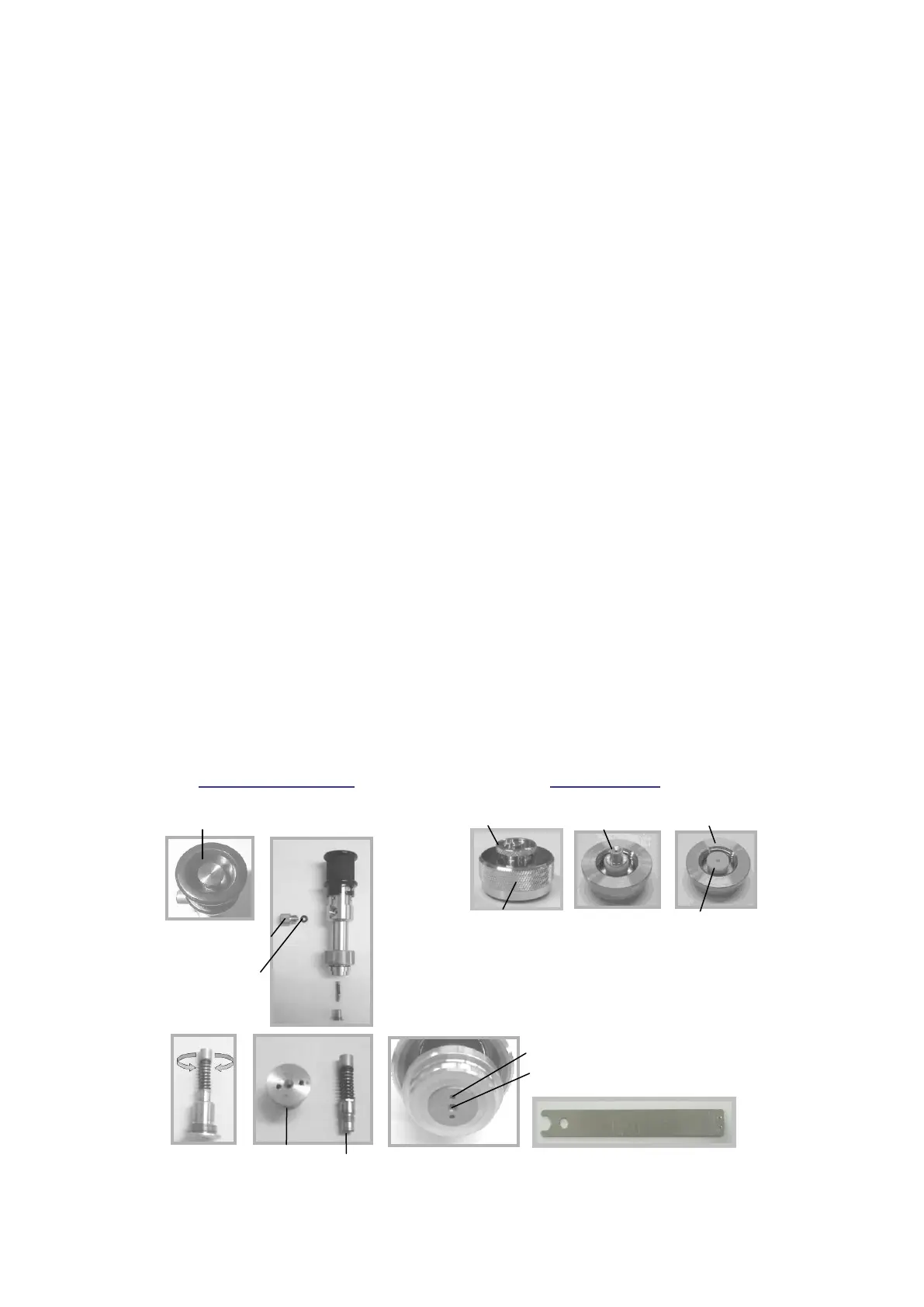

(2) Liquid sampler

Replace the septum (P/N:PY1-2025). There is no need to perform maintenance work; however, the

septum should be regularly replaced to avoid unexpected troubles

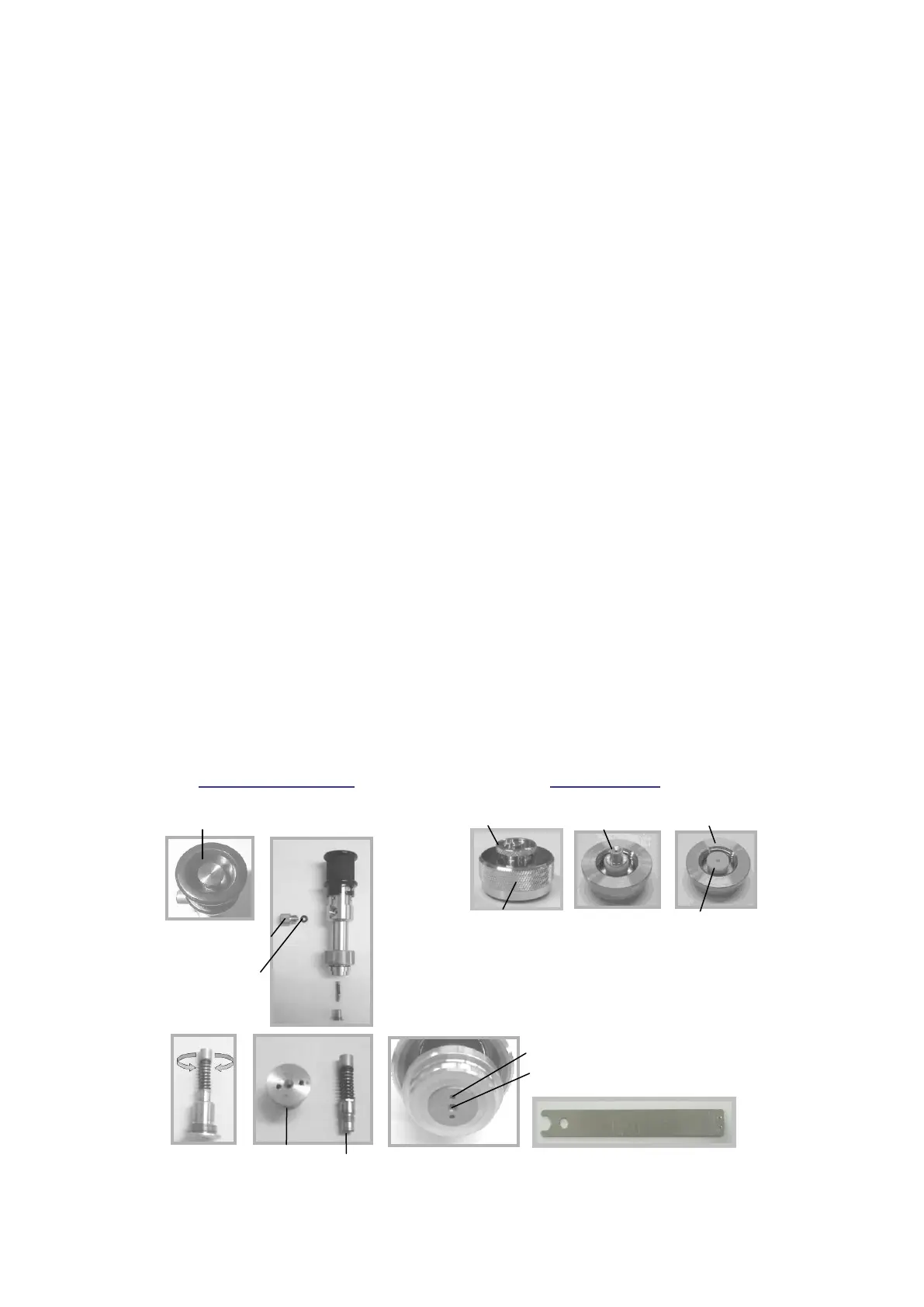

(3) Double-Shot sampler

a) Make sure that the slider moves smoothly. If there is difficulty, slide it up and down several

times until it moves smoothly; if this fails to smooth out the movement it may be necessary to

disassemble it prior to cleaning. After cleaning, a lubricant must be applied. Contact us if you

prefer it to be re-conditioned at Frontier Labs (charged).

b) Check the O-ring for air purge valve for any damage. The damage can lead to gas leakage.

c) The mounting surface of the sampler is a mirror finish. Contamination or scratches on the

surface can result in gas leakages. When storing the sampler, the surface should be

protected.

Holes for removintg chuck base

Chuck base remover

(PY1-3573)

Needle guide φ0.8A

(PY1-7412)

Septum holder A

(PY1-1038)

Loading...

Loading...