6-11

Ver.1.36

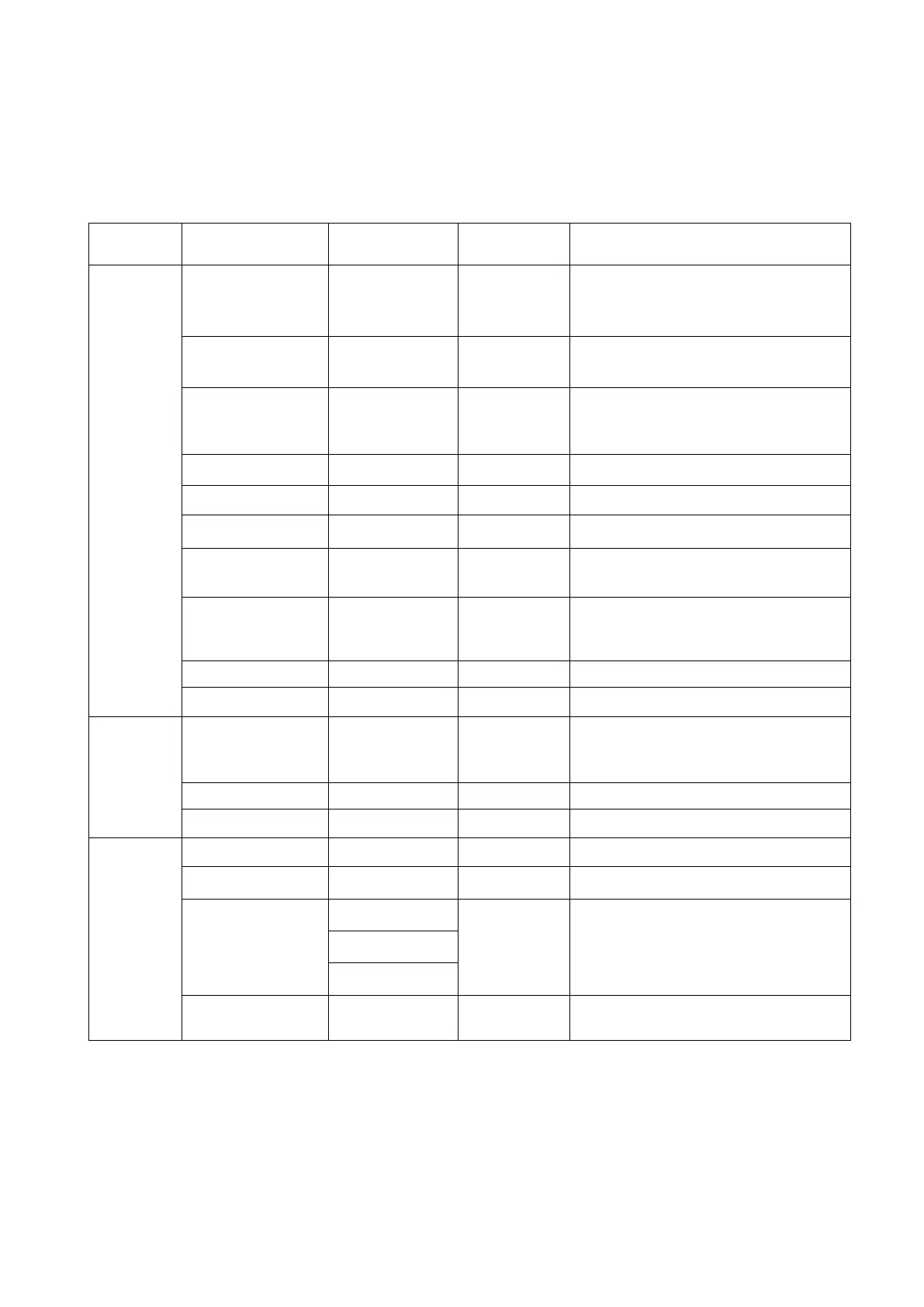

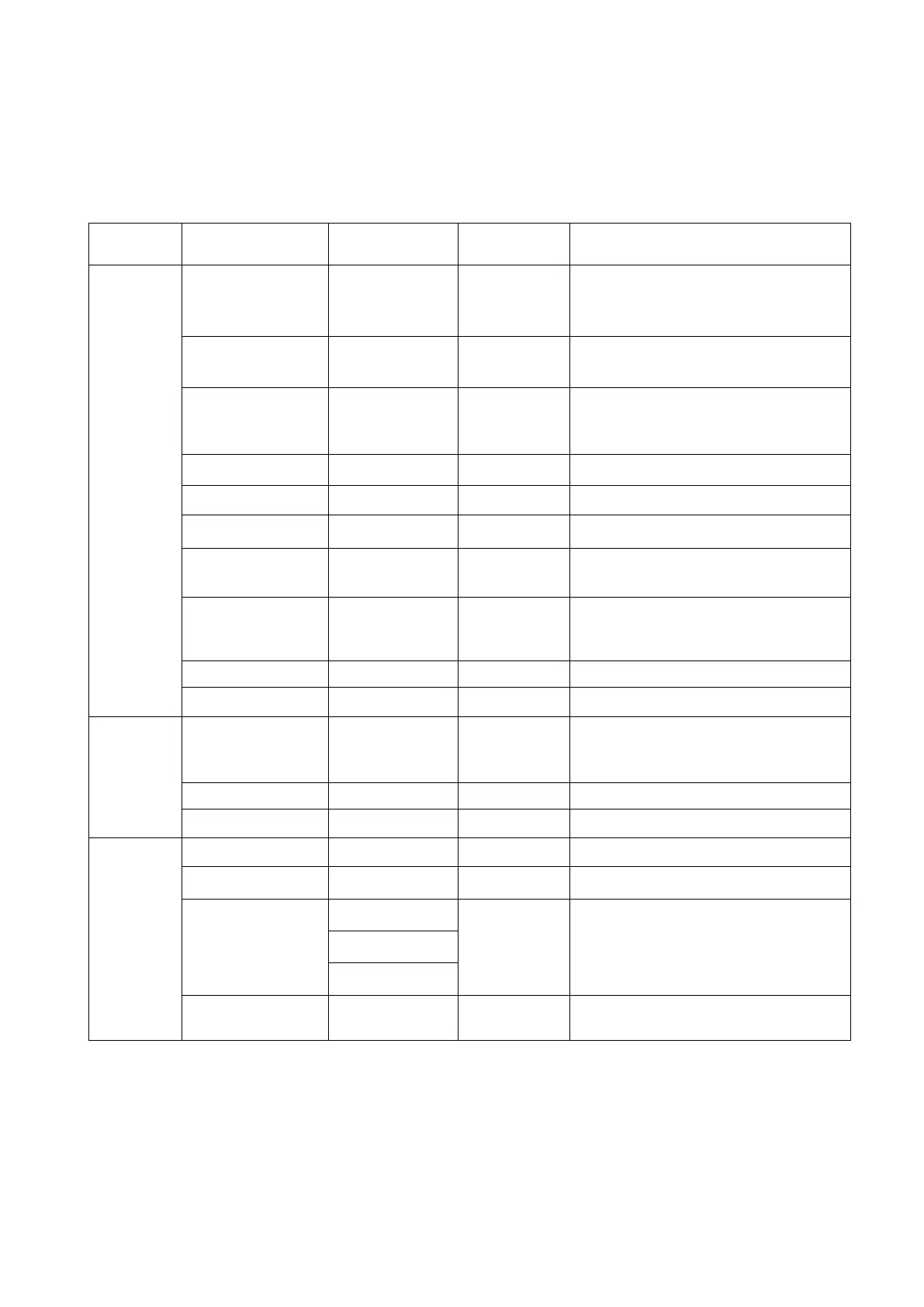

6.2.5 List of recommended replacement parts

Pats listed below are consumable parts that are recommended to replace during maintenance work.

The replacement interval raries depending on the usage.

6.2.6 Periodic maintenance and inspection

We recommend that the pyrolyzer be overhauled and inspected every two years and that

hard-to-replace parts such as heater and thermal insulator be replaced for your stable and safety

operation of the product.

Quartz pyrolysis tube

A30

Replacement interval depends on type of

samples, amount used, and number of runs.

Can be heat-cleaned with torch flame.

Replace when pyrolysis tube M30 is replaced.

Replacement recommended when pyrolysis

tube M30 is replaced.

Over tightening injector septum may clog

needle opening with septum debris.

Standard accessory for EGA/PY-3030D

Used when Auto-Shot sampler is used.

For sealing pyrolysis tube M30, 2 pcs used

Replacement not needed when Auto-Shot

Sampler is used all the time.

Septa for liquid

sampler, 20 pcs

Inspection may only be needed if liquid sample

injection with micro syringe is not done.

Used for carrier gas tube joints

Worn-out chuck does not hold eco stick firmly.

Special tool required.

The product needs to be returned to F-Lab.

Replace when trap tube is replaced. 4 pcs

used.

Replace if leakage detected when pyrolyzer

interface or GC injector cools down.

Replace when pyrolyzer is removed from GC

injector.

Other parts that GC

manufacturers

recommend

Loading...

Loading...