Ver.1.36

About cooling time of pyrolyzer furnace

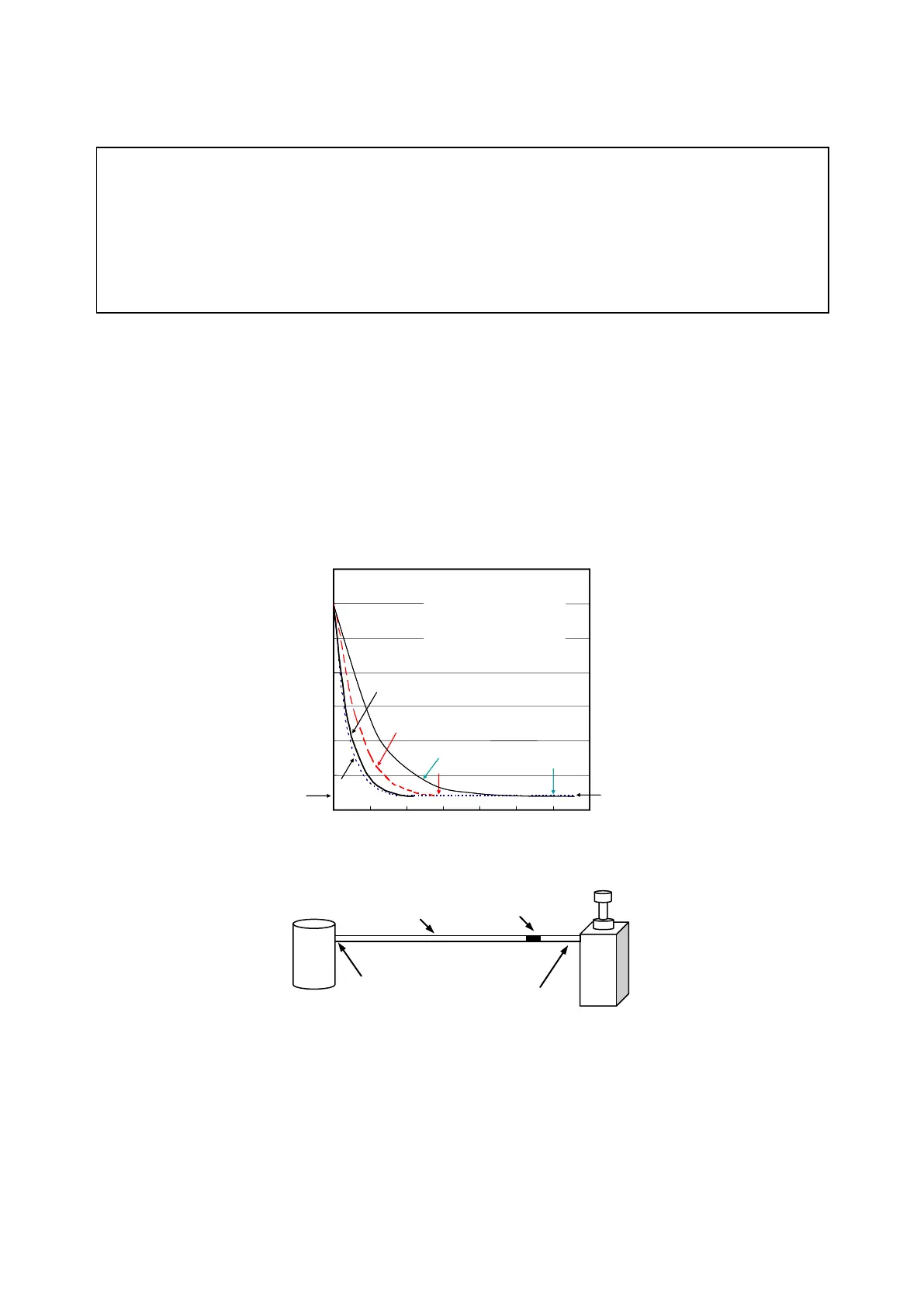

Fig. 2.1 shows the relationship between pyrolyzer furnace temperature and cooling time with varied

cooling air pressures. The pressures (P) here are ones measured at the outlet of nylon tube

(PY1-7801) that feeds air to the pyrolyzer.

Other requirements and utilities

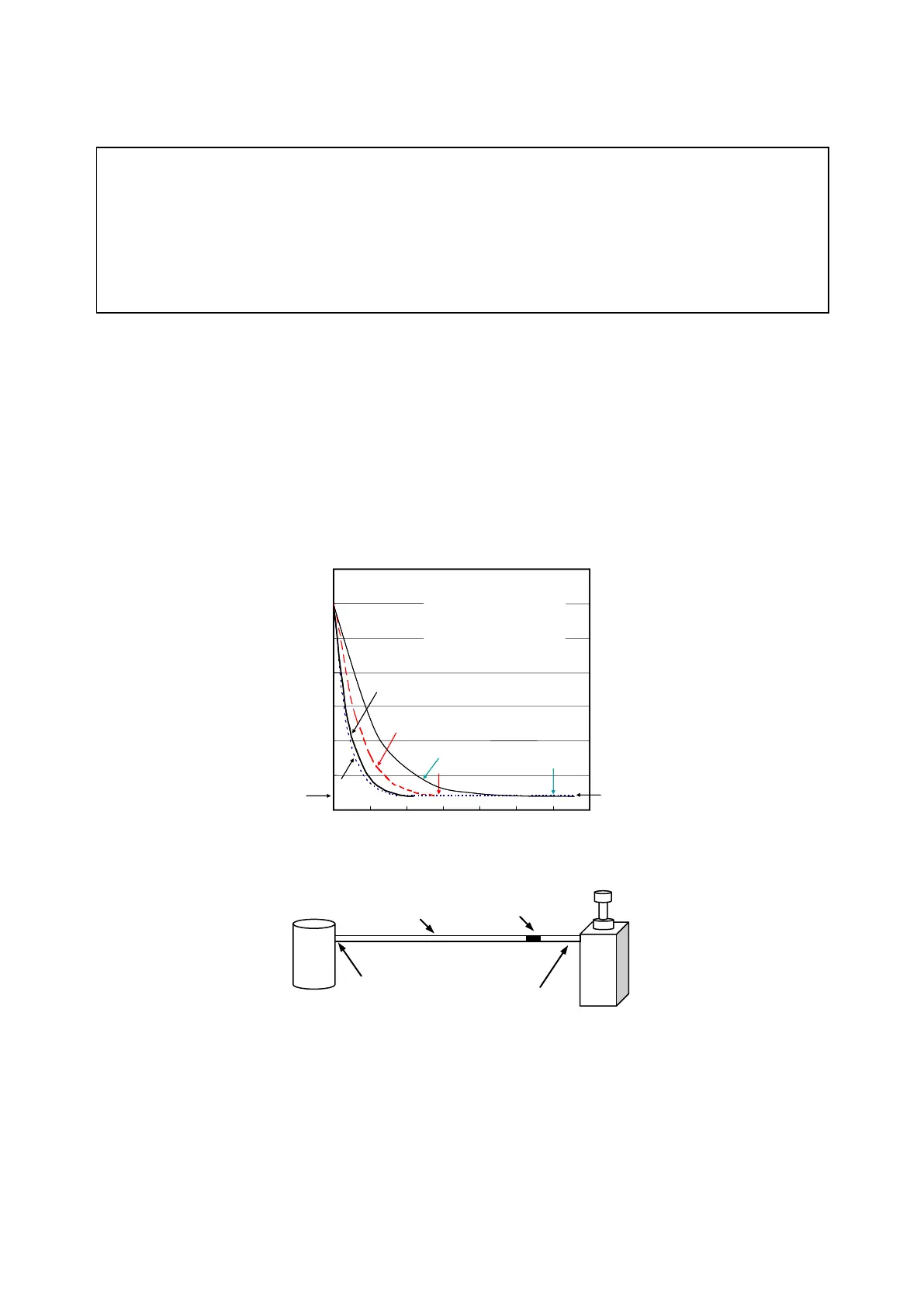

1) Gas chromatograph (with a split/splitless injection port): some limitations in installation depending on GC model.

2) Multi-shot pyrolyzer: pyrolysis furnace cooling gas (nitrogen or compressed air, pressure: 400-600kPa) supplied via o.d. 1/8 in

or 3 mm pipe (cupper or stainless steel), readily accessible from the temperature controller of pyrolyzer (operating flow rate: 7

L/min)

3) Power outlet: AC100/120V or AC200/240V, 400W (MAX) with 3P socket

4) Control PC: A PC running Windows 10, 8.1, 8, 7, Vista, or XP operating system with a USB port. If the recommended GC or

GC/MS is used, the PC can be shared with GC/MS control software programs.

Fig. 2.1 Relationship between pyrolyzer furnace temperature and cooling time when varying cooling air

pressure (ambient temperature: 20°C)

0

100

200

300

400

500

600

700

0 5 10 15 20 25 30

Cooling time (min)

Furnace temp (℃)

170 kPa

100 kPa (Standard)

50 kPa

0.1 kPa (Home aquarium pump)

40℃

Cooling time from 600℃ to 40℃

170 KPa (15 Lmin): 11 min

100 KPa ( 7 L/min): 13 min

50 KPa (3.4 L/min): 14 min

< 0.1 kPa (0.2 L/min): 30 min

40℃

0

100

200

300

400

500

600

700

0 5 10 15 20 25 30

Cooling time (min)

Furnace temp (℃)

170 kPa

100 kPa (Standard)

50 kPa

0.1 kPa (Home aquarium pump)

40℃

Cooling time from 600℃ to 40℃

170 KPa (15 Lmin): 11 min

100 KPa ( 7 L/min): 13 min

50 KPa (3.4 L/min): 14 min

< 0.1 kPa (0.2 L/min): 30 min

40℃

Loading...

Loading...