Ver.1.36

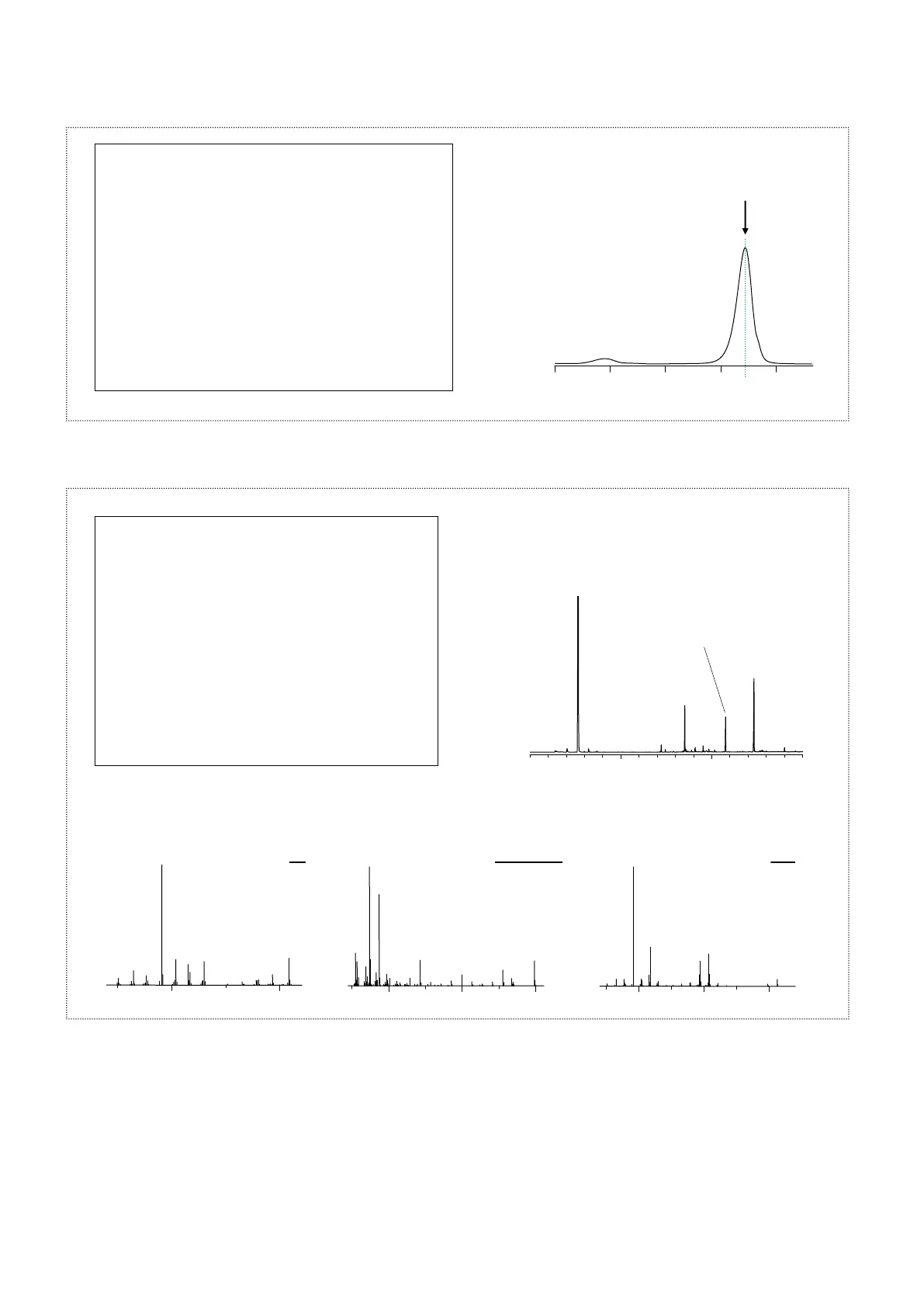

Fig. 8.1 Test conditions and a typical EGA thermogram

Analytical conditions

ITF tube : EGA tube

(deactivated metal capillary, L=2.5 m, id.=0.15 mm,

no stationary phase)

Column flow : 1.0 ml/min

Split ratio : 1/100

Oven temp. : 300°C (isothermal)

Injector temp. : 300°C

Py furnace temp. : 100 - 550°C (20°C/min)

Py-GC ITF temp. : 300°C (AUTO mode)

Sample : Polystyrene (contains 5 wt% methyl stearate)

Sample wt. : 125 µg (5µl of 25 µg/µl dichloromethane solution)

Sample cup : Eco-Cup LF

Detector : MS or FID

GC/MS ITF temp. : 300°C

Scan range : 29 - 350 (m/z)

Scan speed : 0.1 scan/sec

Peak apex temperature

(RSD ≤ 0.3%, n=3)

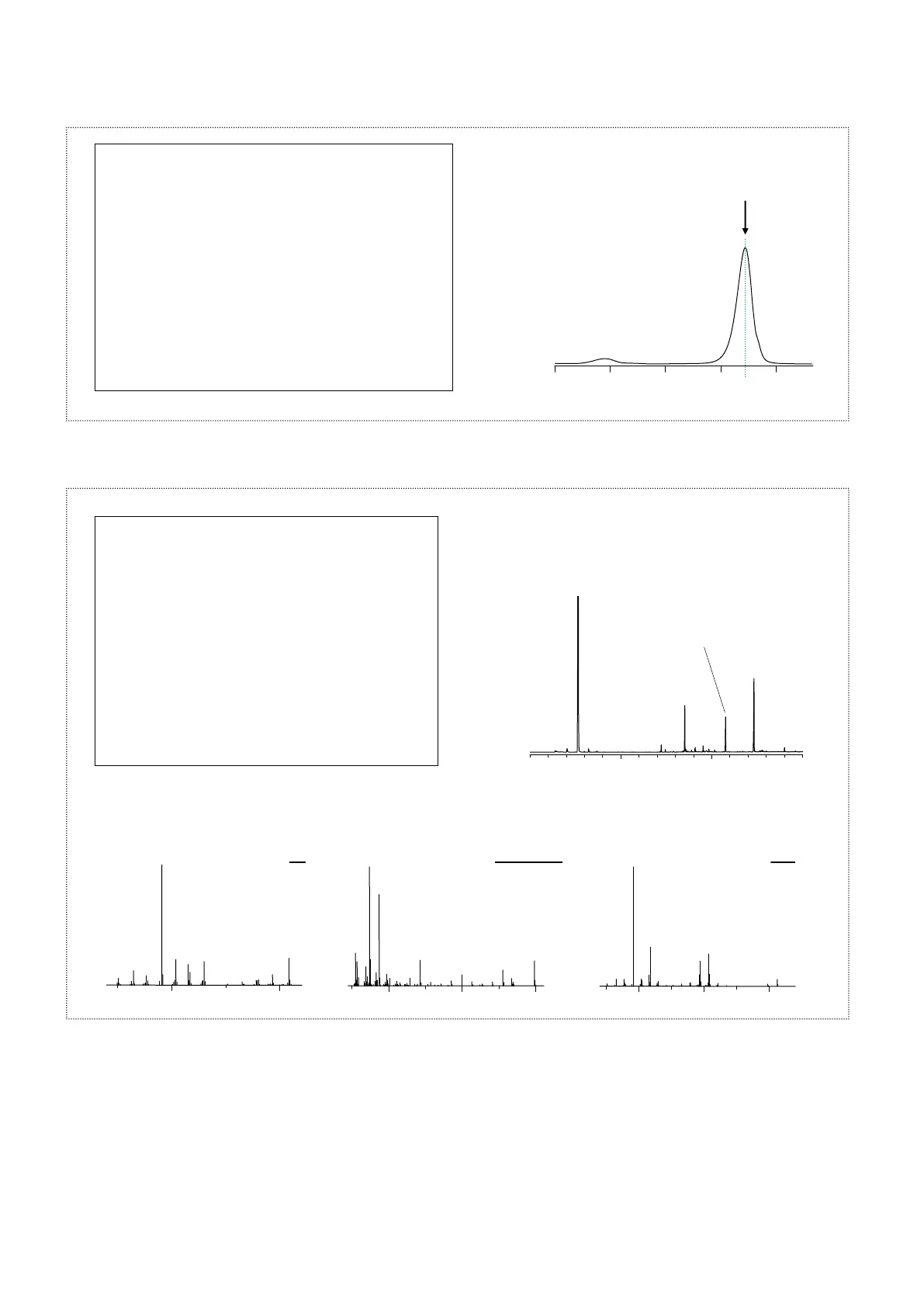

Fig. 8.2 Test conditions and a typical check-out sample pyrogram

Analytical conditions

Separation column : Ultra ALLOY

+

-5

(5% phenyl 95% dimehtylpolysiloxane

L=30m, id.=0.25mm, df=0.25 µm)

Column flow : 1.0ml/min

Split ratio : 1/100

Oven temp. : 70 - 320°C (20°C/min, 1 min hold)

Injector temp. : 300°C

Py furnace temp. : 550°C

Py-GC ITF temp. : 300°C

Sample : Polystyrene (contains 5 wt% methyl stearate)

Sample wt. : 25 µg (5µl of 5µg/µl dichloromethane solution)

Sample cup : Eco-Cup LF (single cup used)

Detector : MS (200V lower than that of Autotune)

GC/MS ITF temp.: 300°C

Scan range : 29 – 350 (m/z)

Scan speed : 3 scans/sec or greater

Mass spectra of maijor peaks

Peak ratio of SSS / Me-Stearate

RSD ≤ 2% (n=3)

Loading...

Loading...