CHAPTER 12: OIL FILTRATION (Surface Ship Only)

12-3

13. Return filter pan to cabinet.

14. Skim large particles from the vat to be

filtered.

14. With the oil at operating temperature and

the fryer off, open valve of vat to be drained.

Caution: the oil is at or near operating

temperature during filtering. Fig: 12-14, 16

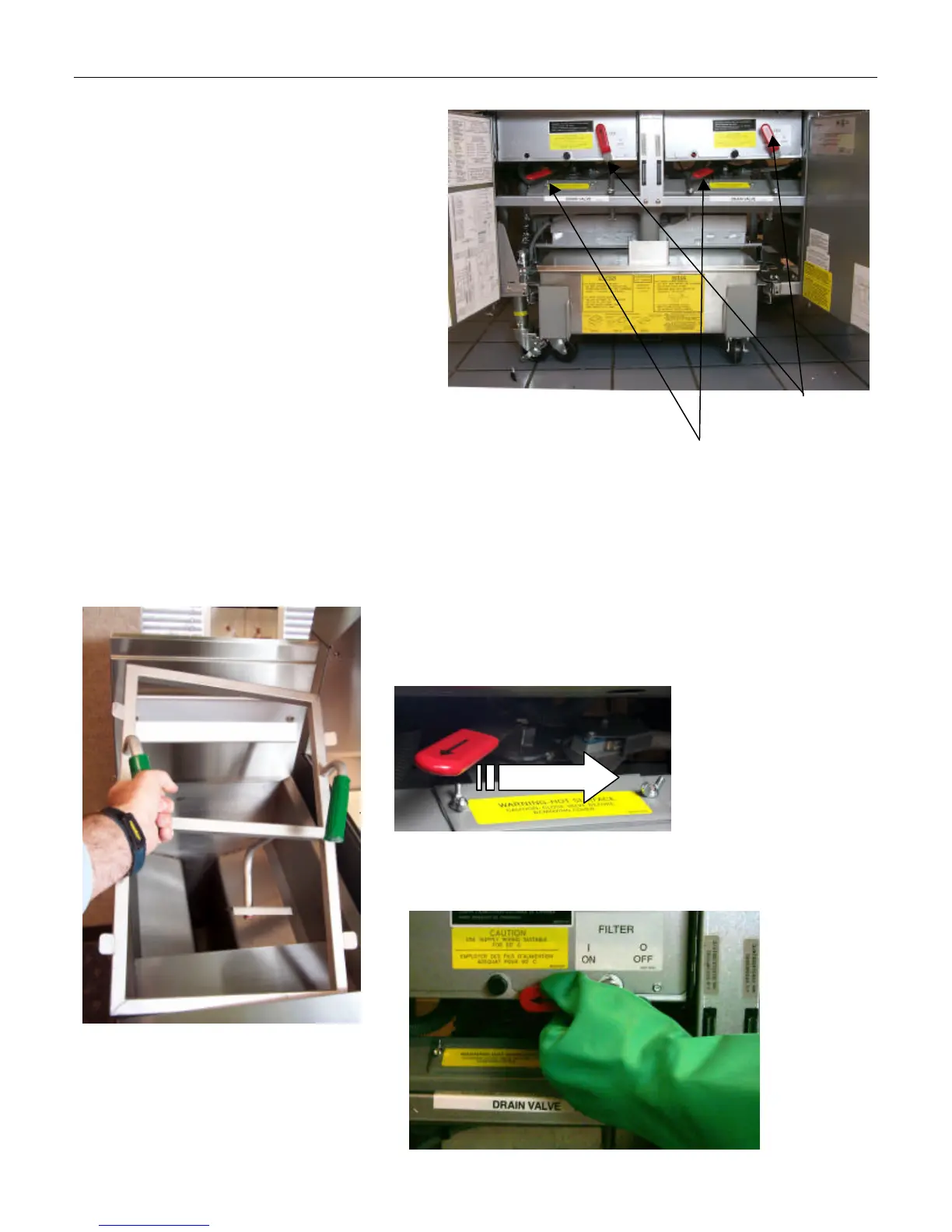

16. Snap the power shower into the frypot

connection. Fig: 12-15

17. For fryers with rear flush option, engage

the control lever to select rear flush. This

will wash sediment from the bottom of the

frypot.

18. Turn the filter pump on. Fig: 12-17

19. The oil is pumped back into the frypot. If

polishing of the oil is desired, allow pump to

run with the drain valve open for no more than

five minutes.

20. At the end of the filter process, close the

drain and allow the pump to run as the oil fills

up the frypot.

21. When the filter pan empties, air will be pumped into the frypot, causing the oil in the frypot to bubble.

Allow bubbling to continue 15 to 20 seconds before shutting off

filter pump. This action ensures the oil-return lines are clear of

oil.

22. Remove Power Shower. Fig: 12-15

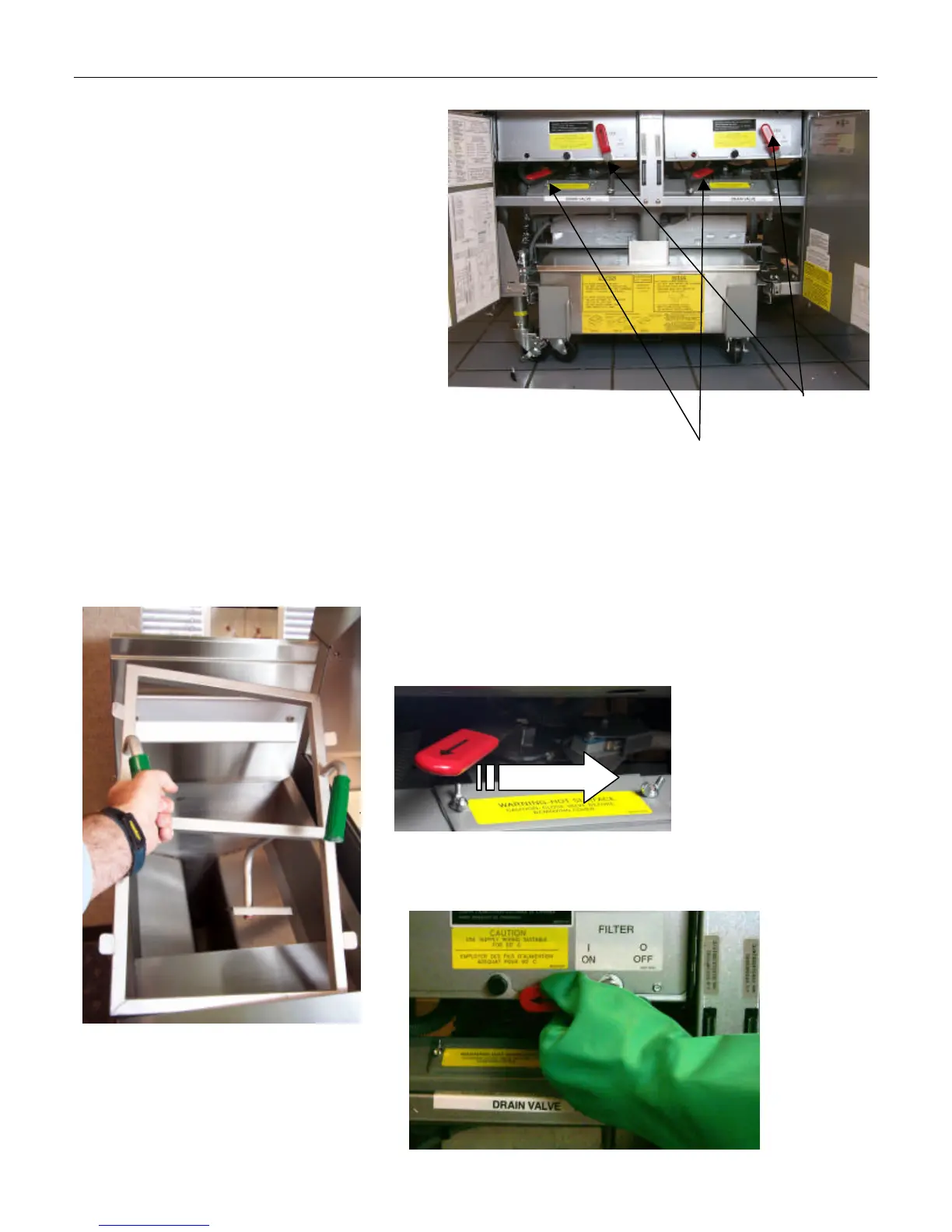

Handles used during filtering:

valves

pump

handles

With the oil above 300 degrees, move

the handle to the right to empty the

frypot into the filter pan.

Fig: 12-17

The filter pump

moves oil from

the drain pan to

the frypot.

Fig: 12:15

A Power Shower is shown being

placed in a frypot. Filtered oil returning

to the frypot flows through the device

and down the sides of the vessel,

cleaning the pot walls.

Fig: 12-16

Loading...

Loading...