EP18-72-IOMM-2015-7

Fulton Ltd

Page 35

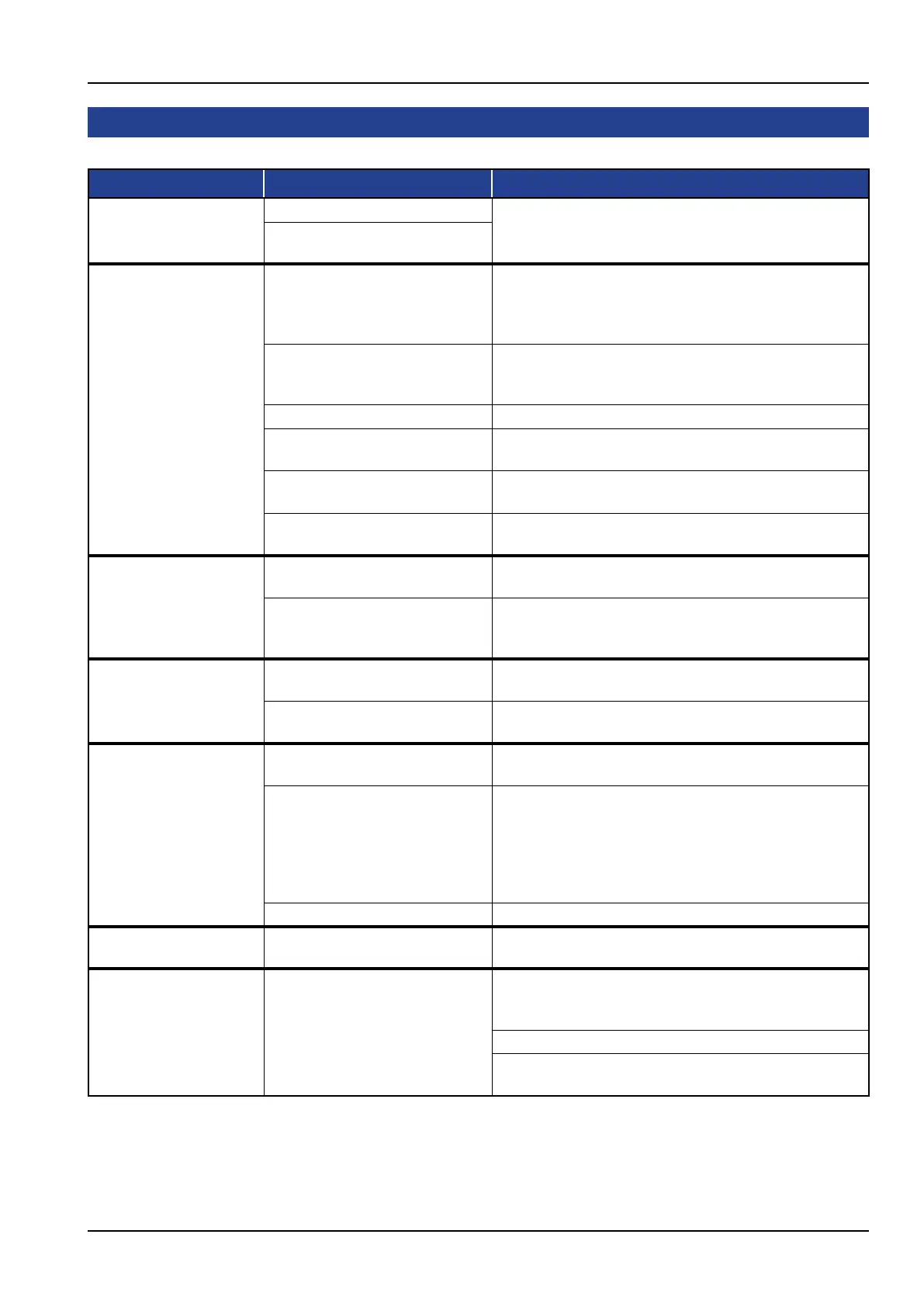

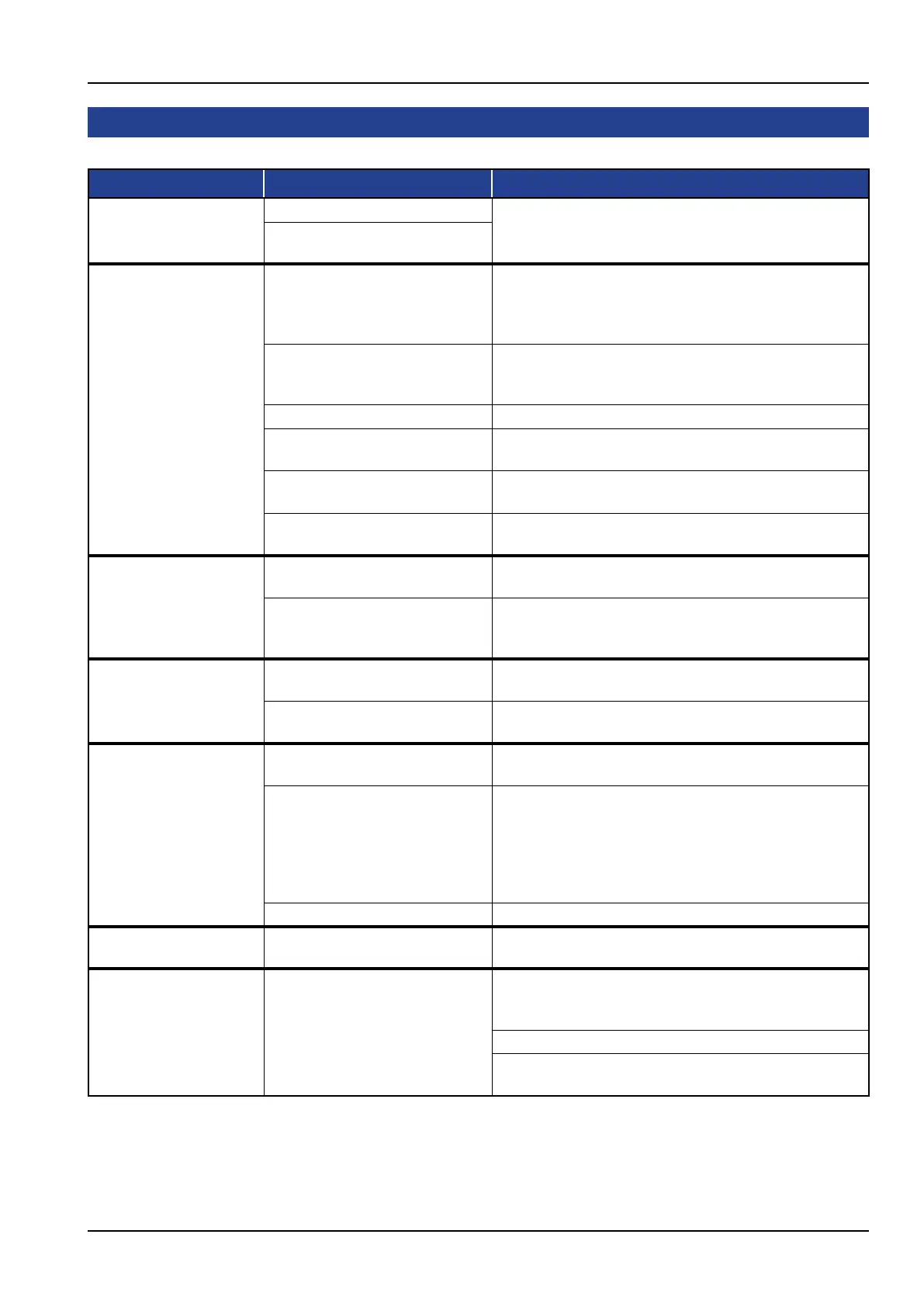

MAINTENANCE - 4

4.8.1 TROUBLESHOOTING BOILER

Problem Cause Remedy

Circuit Live indicator

not illuminated

1. Mains supply failure. External circuit MCB requires resetting.

Fuses need replacing.

Indicator lamp needs replacing.

2. Door interlock microswitch

not made.

Boiler Low Water

lamp illuminated and

Audible alarm sounds

1. Insufcientwaterinthe

boiler.

Check that the feedwater supply line valves are

open. Check that the ball valve in the tank is

operating correctly by removing the inspection cover

on the tank.

2. Obstruction in the feedwater

line to the pump.

Check that the shut-off valve below the tank is open.

Remove andcleanthelterinthestrainer.Check

that the non-return valve is operating correctly.

3. Air lock in the pump. Bleed the pump at the point provided.

4. Feedwater pump impeller

worn.

5. Incorrect connections to

water level probes.

Check connections to water level probes.

6. Faulty water level relay. Check that each relay is pressed rmlyhomeonits

base.

High Pressure

Audible alarm sounds

1. On/Off Pressure Control

failure.

2. High pressure controller set

too close to on/off control

setting.

Feed Water Tank Low

water indicated

1. Low Water. Check that water supply line valves are open. Check

the feedwater solenoid valve is opening.

2. Faulty water level relay. Checkthatthefeedwaterrelayispressedrmly

home on its base.

Pump Fault indicated 1. Electrical fault in the

feedwater pump circuit.

Check the circuit fuse, replace as required.

2. Thermal overloadttedto

the pump motor contactor

requires re-setting.

Check that the unit has been set to the correct

amperage and adjust if necessary. If the fault

continues after the controls have been reset, a

major fault exists which can only be corrected by

a competent person with correct electrical test

equipment.

3. Faulty pump overload.

Element Fault 1. MCB requires re-setting. If the fault persists the element and the circuit must

be fully checked by a competent person.

Tank Low Water

indicated

1. Insufcientwaterinthetank Check the valves in the feedwater supply line

are open. Check the feedwater solenoid valve is

opening.

Incorrect connections to the tank water level probes.

Faulty water level relay, check that each relay is

pressedrmlyontoitsbase.

Note: Unless a faulty element is allowing steam or water to escape it is safe to operate the boiler with the faulty

element tted provided that the element selector switch has been switched off.

Note: Open circuit element faults will not be detected by the element fault detection system.

Loading...

Loading...