EP18-72-IOMM-2015-7

Fulton Ltd

Page 43

APPENDIX - A

Specication

TI-115-EP18-72-DS-2017-9

Page 2 of 2

Every effort is made to ensure accuracy at time of going to press. However as part of our policy of continual product improvement, we reserve the right to alter specications without prior notice.

Telephone: +44 (0) 117 972 3322

Fax: +44 (0) 117 972 3358

E-mail: sales@fulton.co.uk

Website: www.fulton.co.uk

Fulton Ltd

5 Fernhurst Road, Fishponds, Bristol.

BS5 7FG. England.

003

FM 28400

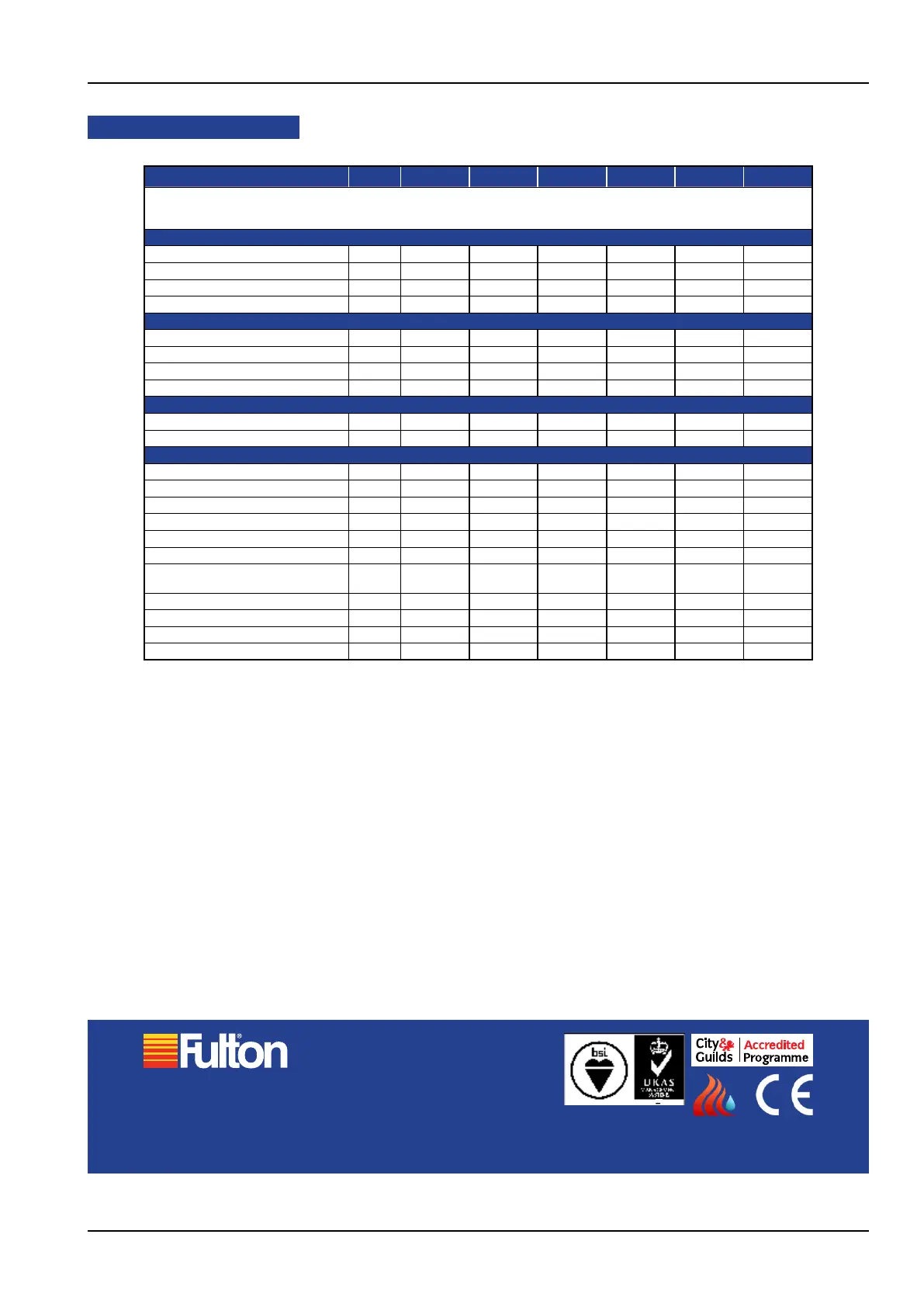

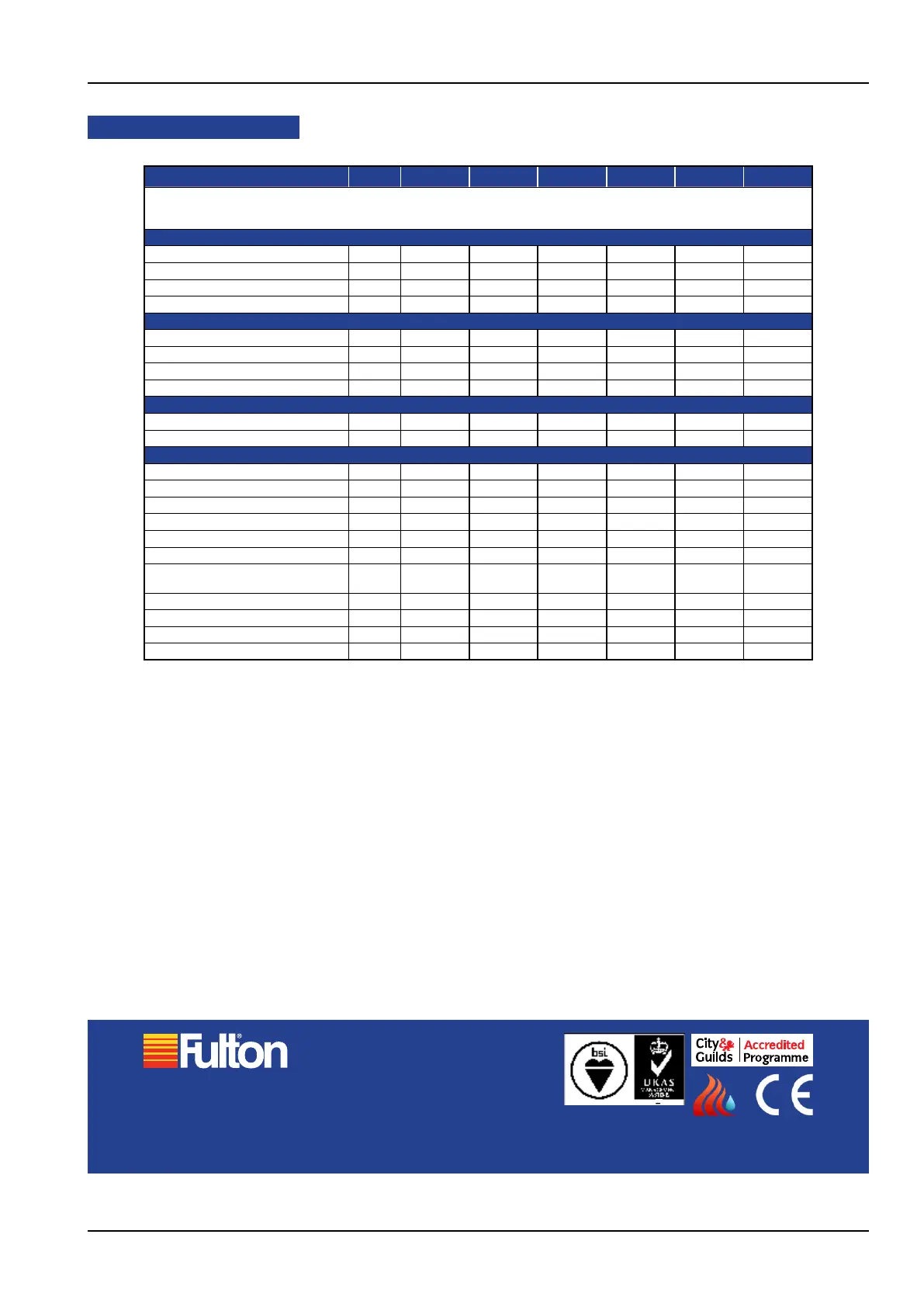

MODEL: ELECTROPACK UNIT EP18 EP24 EP36 EP48 EP54 EP72

Designed and manufactured to BS EN 13445:2009 and PED 2014/68/EU.

General

Steam Output F & A 100°C kg/h 29 38 57 77 86 115

kW Rating kW 18 24 36 48 54 72

Operating Pressure barg 10.34 10.34 10.34 10.34 10.34 10.34

Number of Elements 1 1 2 2 3 3

Weight

Shipping Weight kg 390 390 390 390 390 390

Operational Weight kg 560 560 560 560 560 560

Boiler working water volume L 38 38 61 61 84 84

Feed Tank Volume L 77 77 77 77 77 77

Electrical Requirements

FLC 400 V 3 ph 50 Hz** A/ph 32 40 58 75 84 110

FLC 230 V 1 ph 50 Hz*** A 86 112 164 216 242 320

Connection Sizes All threads BSP F= Female, M=Male

Steam Outlet DN 20 20 20 20 20 20

Safety Valve Discharge DN 25 25 25 25 25 25

Condensate Return DN 15 15 15 15 15 15

Feedwater Inlet DN 20 20 20 20 20 20

Feedwater Pump Inlet DN 25 25 25 25 25 25

Blowdown, Boiler DN 20 20 20 20 20 20

Blowdown, Water Level Gauge

(Sight Glass) - where tted

DN 15 15 15 15 15 15

Feedwater Tank Vent DN 40 40 40 40 40 40

Feedwater Tank Drain DN 15 15 15 15 15 15

Feedwater Tank Overow DN 25 25 25 25 25 25

Water Sample Outlet DN 15 15 15 15 15 15

** 6 A/ph for feedwater pump & standard control circuit, included.

*** 7.5 A for feedwater pump & standard control circuit, included.

Note: Electrical enclosures are rated IP20

Loading...

Loading...