Warning

Connecting connectors

Be sure to insert the connector until it stops at

the deepest point.

How to protect the receiver from vibration and

water

Wrap the receiver with something soft such

as foam rubber to avoid vibration. If there is

a chance of getting wet, put the receiver in a

waterproof bag or balloon to avoid water.

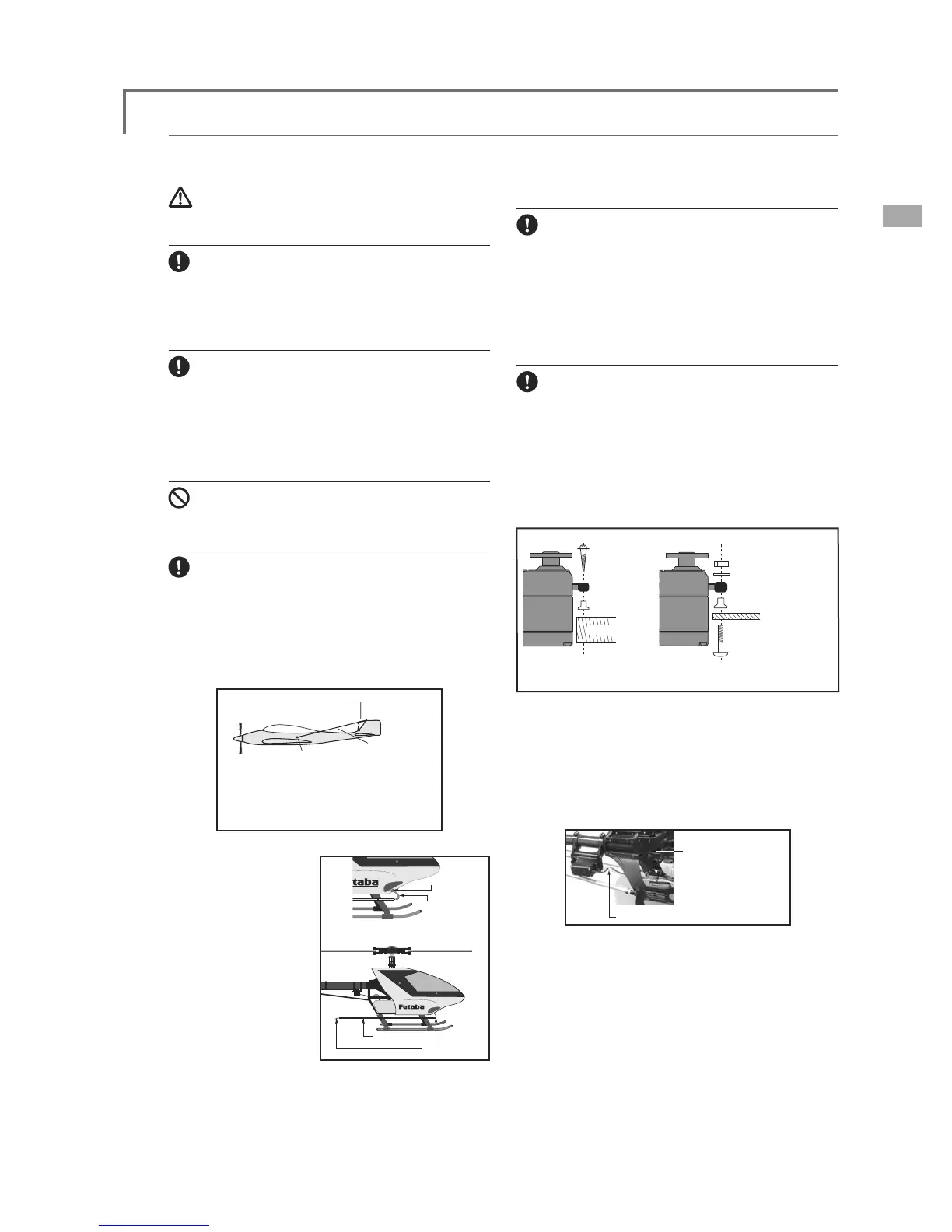

Receiver's antenna

Never cut the receiver's antenna. Do not bind

the receiver's antenna with the cables for

servos.

Locate the receiver's antenna as far as possible

from metals or carbon fiber components such

as frames, cables, etc.

*Cutting or binding the receiver's antenna will reduce the ra-

dio reception sensitivity and range, and may cause a crash.

ƔUse rubber band to stretch

antenna and then fix it.

ƔUse a rubber bushing to the position where

antenna is coming out from the airframe so

that the antenna won't be cut due to the

friction.

ƔUse rubber band to stretch antenna and then

fix it.Make a knot inside of the airframe so that

the antenna will not fall out.

Antenna

Antenna-exiting

hole

Rubber grommet or

silicon tube, etc.

Antenna

Nonmetal tube

*Use rubber grommet or

silicon tube to protect

the antenna from being

cut or from its insula-

tion peeling off at the

fuselage antenna-exit

hole.

*Place the receiver anten-

na out from the fuselage

part to the nonmetal

tube installed in skid

etc. Please keep antenna

away from parts made

of metal and carbon

graphite.

Servo throw

$GMXVW\RXUV\VWHPVRWKDWSXVKURGVZLOOQRW

bind or sag when operating the servos to the

full extent.

*If excessive force is continuously applied to a servo, your

aircraft may crash because the servo would be damaged

and the battery would be consumed rapidly.

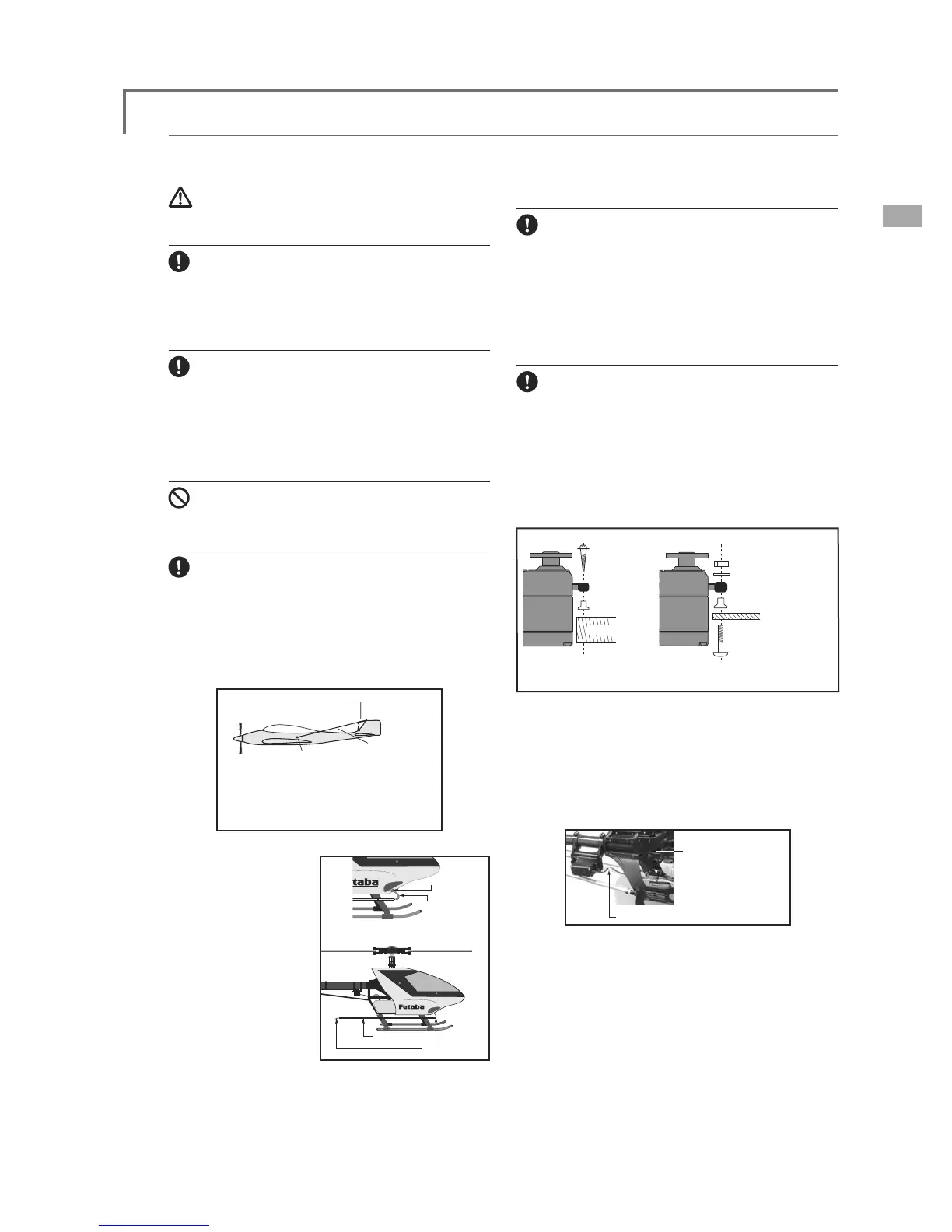

Mounting servos

Use a vibration-proof rubber (such as rubber

grommet) under a servo when mounting the

servo on a servo mount. And be sure that the

servo cases do not touch directly to the metal

parts such as servo mount.

*If a servo case is contacting directly to the airframe, the

vibration of the airframe directly travels to and may dam-

age the servo.

Rubber

grommet

Brass eyelet

Wood screw

Servo mount

2.3-2.6mm nut

washer

Rubber

grommet

Brass eyelet

Servo mount

2.3-2.6mm screw

(Helicopter)(Airplane/Glider)

Servo lead wires

To prevent the servo lead wires from being

EURNHQE\YLEUDWLRQGXULQJÀLJKWSURYLGHDPDUJLQ

so that the wire sticks out slightly and fasten it at

suitable points. In addition, periodically check the

wire during daily maintenance

Fasten about 5-10cm

from the servo outlet

so that the lead wire

is neat.

Margin in the lead wire.

Mounting the power switch

When mounting a power switch to an airframe,

make a rectangular hole that is a little larger than

the total stroke of the switch so that you can turn

the switch ON/OFF without binding.

Avoid mounting the switch where it can be

covered by engine oil and dust. In general, it is

recommended to mount the power switch on the

VLGHRIWKHIXVHODJHWKDWLVRSSRVLWHWKHPXIÀHU

Safety precautions when you install receiver and servos

Loading...

Loading...