Electrical System

30 Installation Guidelines for Spark-Ignited Stationary Emergency Generators

NOTE: The following tables are provided for references purposes only. Refer to the latest NEC, state and local

AHJ requirements for proper sizing of power and control wires.

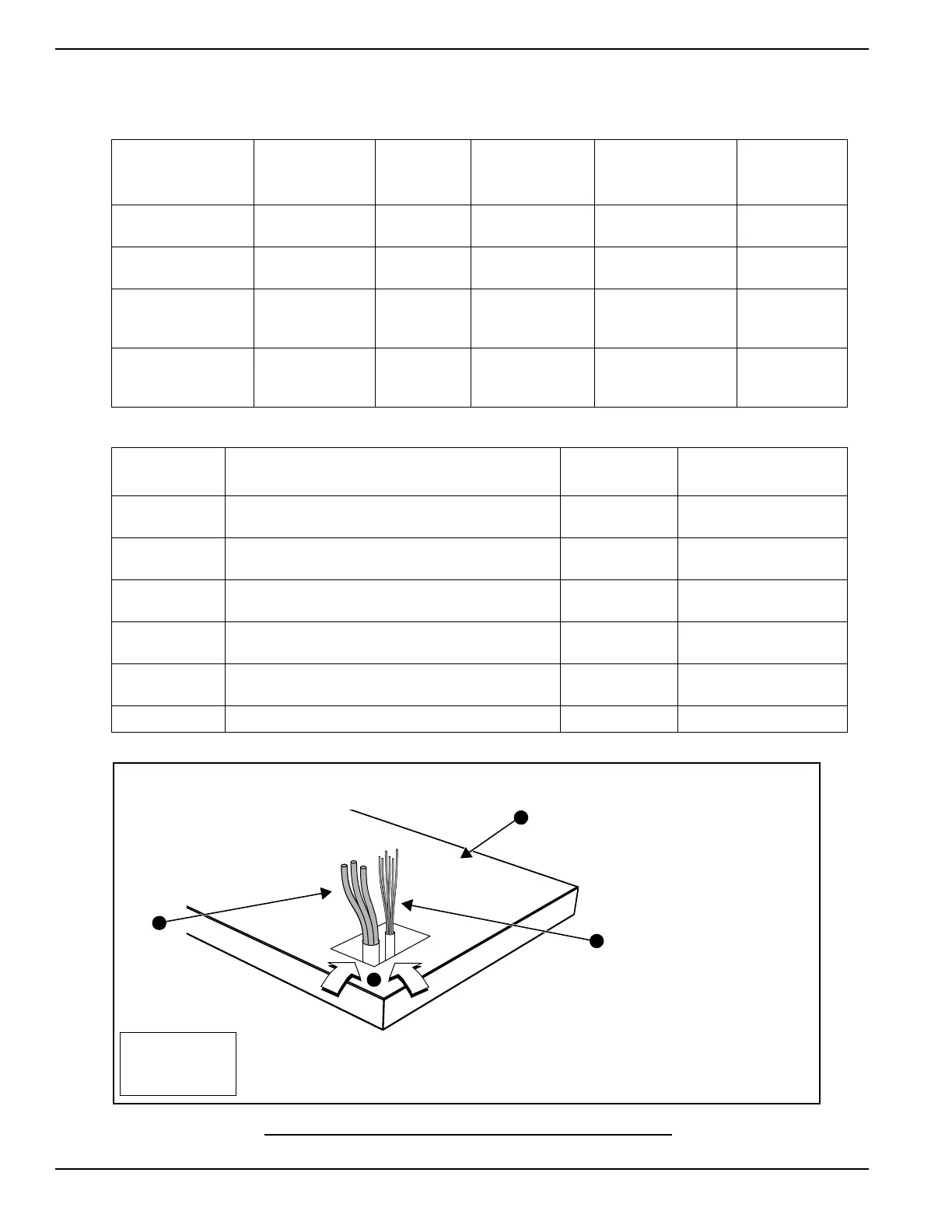

Figure 6-2. Typical Load Leads and Control Wiring in Stub Up

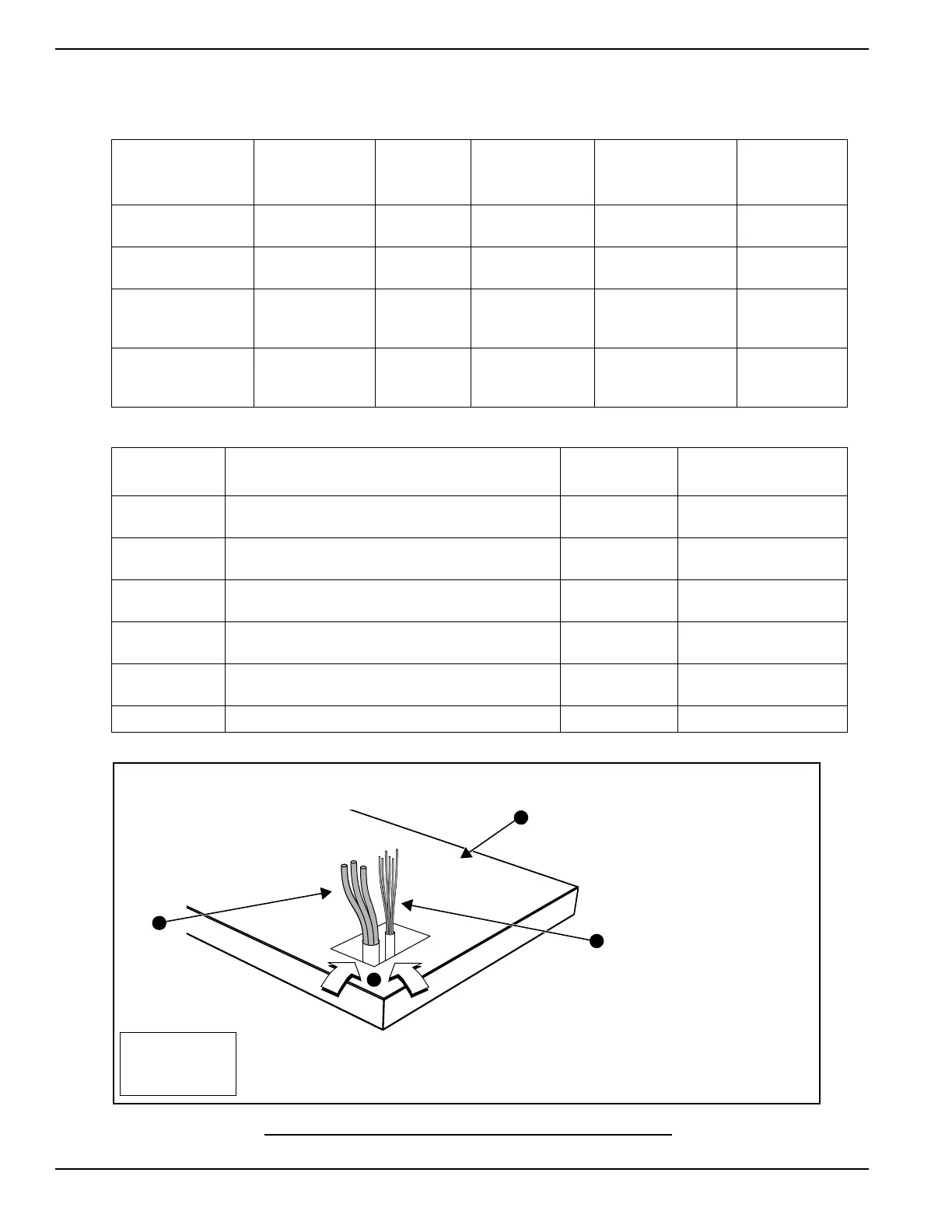

Table 6-1. Frame Breakers

Frame Breaker Range Wire Type

Wire

Temperature

Rating

Lug AWG Range

(Number of

Conductors)

Torque

to Wire

Generac 225 AF

2 Pole

125A-200A Cu/Al 167º F (75º C) 6-350 kcmil (1) 375 in-lb

Generac 225 AF

3 Pole

50A-200A Cu/Al 167º F (75º C) 6-350 kcmil (1) 375 in-lb

Generac 400 AF

2 Pole

225A-400A Cu/Al 167º F (75º C)

1/0-250 kcmil (2)

or

4-600 kcmil (1)

375 in-lb

Generac 400 AF

3 Pole

225A-400A Cu/Al 167º F (75º C)

1/0-250 kcmil (2)

or

4-600 kcmil (1)

375 in-lb

Table 6-2. Terminal Tightening Torques

Amperage

Rating

Description

Cable Screw

Torque

Wire Size Range

15-20 A Load Side, Aluminum Body Lug 32 in-lb

#14 - #8 AWG Cu

#12 - #8 AWG Al

25-35 A Load Side, Aluminum Body Lug 36 in-lb

#8 - #6 AWG Cu

#8 - #6 AWG Al

40-50 A Load Side, Aluminum Body Lug 45 in-lb

#8 - #6 AWG Cu

#8 - #4 AWG Al

55-70 A Load Side, Aluminum Body Lug 50 in-lb

#8 - #4 AWG Cu

#8 - #2 AWG Al

80-100 A Load Side, Aluminum Body Lug 60 in-lb

#4 - #1/0 AWG Cu

#2 - #1/0 AWG Al

10-130 A Line Side, Threaded Contact With Ring Lugs 72 in-lb #14 - #2 AWG

NOTE: Refer to specific NEC

article for routing of control

wires and power wires. AHJ

has final call on single or

dual conduit.

NOTE: Stub up area shown

is for reference only. See

installation drawings for unit

specific details.

A = Load Leads

B = Control Wiring

C = Stub Ups

D = Concrete Pad

A

Loading...

Loading...