<Doc_TEC><Doc_503712400><Rel_B><Lang_EN>

Page 52 av 64

V524

Temperature sensor

3.2 Checking fixed nozzles

This is inspected to prevent the nozzle from becoming clogged with dirt and deposits,

etc. Failure to perform the inspection can result in poor cleaning results.

Unscrew the nozzle from the chamber and clean it inside and out. Mount the nozzle back

again.

3.3 Checking nozzle attachments and hose connections for the nozzles

This is done to minimize the risk of leakage from the chamber and from the hose

system’s connections to the nozzles at the back and on the side of the chamber. Failure to

perform inspections can result in leakage.

Check that the nozzles are properly attached to the inside chamber wall. Tighten them if

loose. Check that the hose connection at the back of the nozzle is sealed tight.

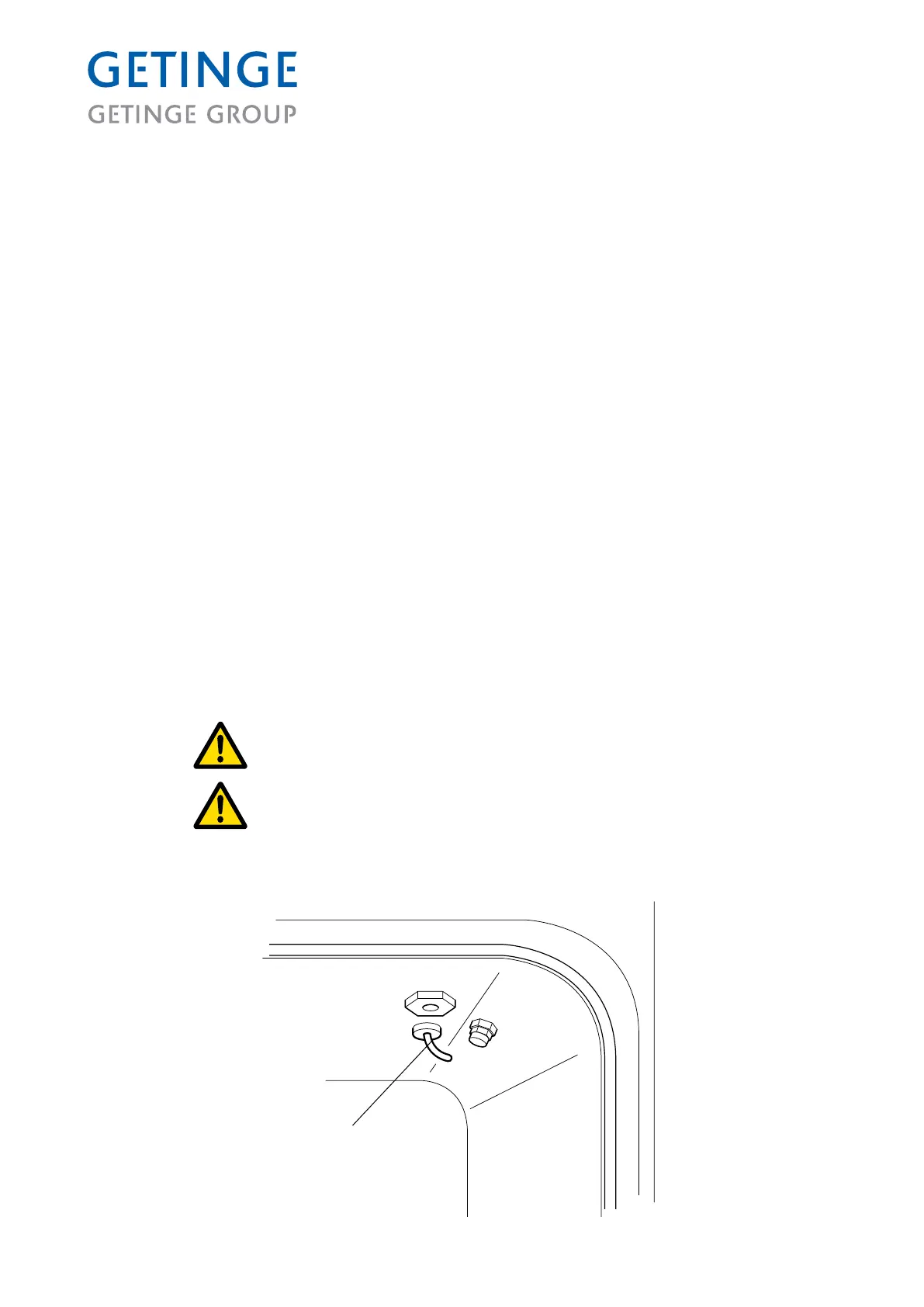

3.4 Checking temperature sensors

This inspection is performed to check that the temperature sensor is working (provides

the correct temperature) and that the lead-in on the top of the chamber is tight. Failure to

perform an inspection can result in poor cleaning results as well as leaking. To check for

leaking, rst run a process. Then remove the front and top of the machine. Pull off the

front and lift off the top. Loosen the screw on the front edge of the unit and lift up the

unit. Check that the surface around the lead-in for the temperature sensor is dry. Replace

the lead-in if necessary. In order to check whether the temperature sensor needs to be

calibrated, compare the temperature in an oil bath. The proper control temperature is

80-90 °C. If the temperature in the machine is incorrect, the temperature sensor must be

recalibrated.

3.4.1 Replacing a temperature sensor

This must only be done by authorized personnel.

The machine is connected to the electricity supply and some components are

live.

• Remove the old temperature sensor by pulling it out of the seal.

• Push the new sensor in through the seal.

Loading...

Loading...