Page 45 av 64

<Doc_TEC><Doc_503712400><Rel_B><Lang_EN>

PREVENTIVE MAINTENANCE

The required maintenance intervals depend largely on the quality of the incoming water

and how often the machine is used. The maintenance interval will have to be determined

in each individual case. We recommend that the stated maintenance operations are done

once or twice a year.

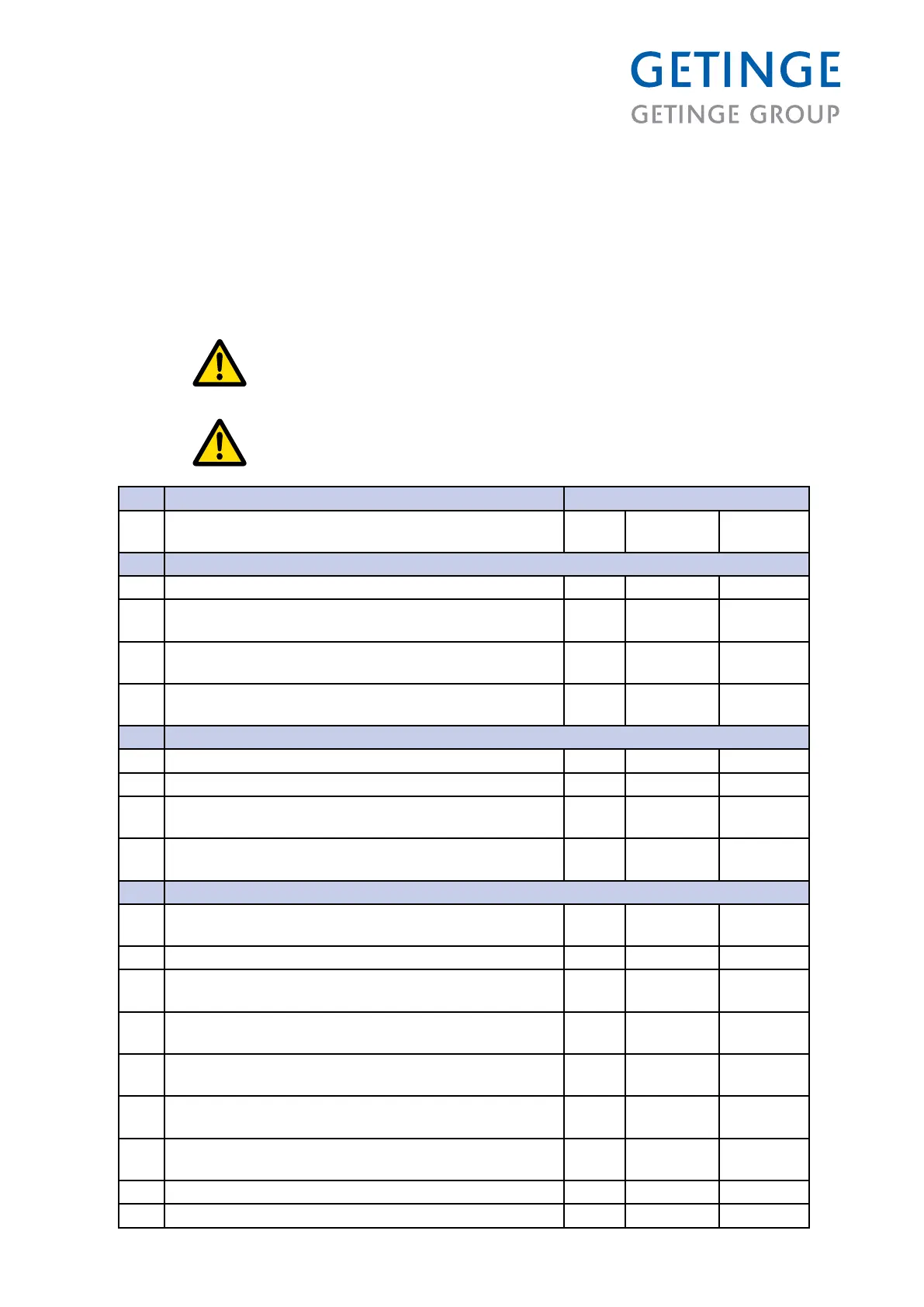

Periodic maintenance

This must only be done by authorized personnel.

The machine is connected to the electricity supply and some components are

live.

Activity / Component Interval

Inspection / Replacement Every

year

Every

other year

Time

required

1 General

1.1 Check the cabling and connection points (page 48) • 10 min

1.2 Check whether the fan is functioning properly, and

clean as needed (free-standing model) (page 49)

• 5 min

1.3 Check the adhesion and condition of the panel decal

(page 49)

• 1 min

1.4 Check that the door lock and breaker are functioning

properly (page 49)

• 10 min

2 Dryer

2.1 Replace HEPA filter (page 49) • 10 min

2.2

Check the function and connection for the fan (page 49)

• 5 min

2.3 Inspect the check valves in terms of their function and

clean as needed (page 50)

• 10 min

2.4 Check the seal and attachment of hoses to the dryer

(page 50)

• 15 min

3 The chamber

3.1 Check the rotating nozzles in terms of their rotation and

clean as necessary (page 50)

• 5-30 min

3.2

Check the fixed nozzles and clean as necessary (page 52)

• 5-30 min

3.3 Check for leakage in the nozzle attachments and the

hose connections to the chamber (page 52)

• 15 min

3.4 Check the temperature sensors in terms for leakage

and function. Calibrate as needed (page 52)

• 15 min

3.5

Check the door seal and chamber seal and clean as needed

Change the seal as needed (page 53)

• 5 min

3.6 Check the mounting for the item holder and adjust as

needed (page 53)

• 5 min

3.7 Check for leakage at the wide waste connection to the

chamber (page 53)

• 5 min

3.8 Cleaning the flushing chamber internally (page 53) • 15 min

3.9

Adjusting the door and door spring as necessary (page 53)

• 15 min

Loading...

Loading...