Start-up 7

0020177748_03 ENERGY Installation and maintenance instructions 17

– if the pH value of the heating water is less than 6.5 or

more than 8.5.

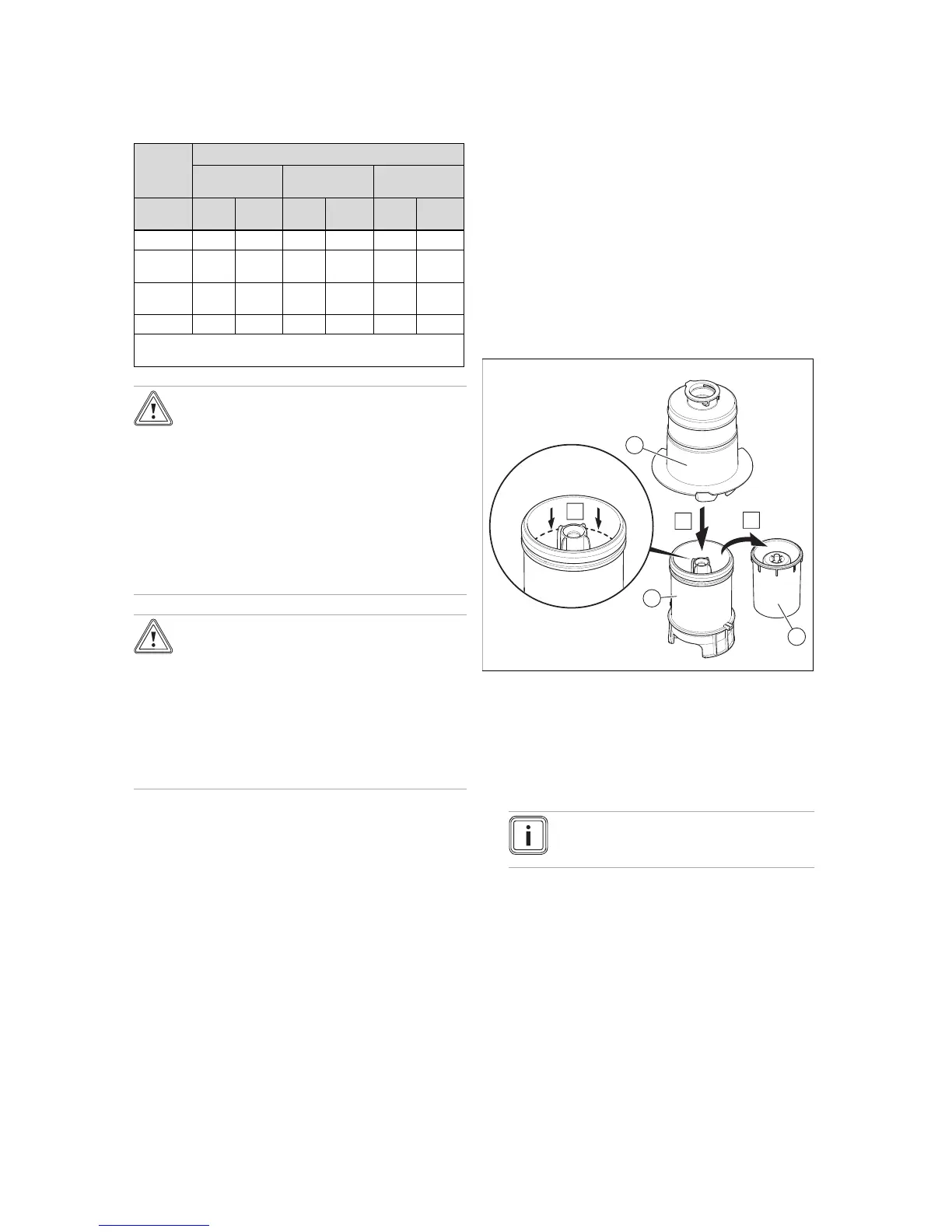

Total

heating

output

Water hardness at specific system volume

1)

≤ 20 l/kW

> 20 l/kW

≤ 50 l/kW

> 50 l/kW

kW

ppm

CaCO₃

mol/

m³

ppm

CaCO₃

mol/

m³

ppm

CaCO₃

mol/

m³

< 50 < 300 < 3 200 2 2 0.02

> 50

to ≤ 200

200 2 150 1.5 2 0.02

> 200

to ≤ 600

150 1.5 2 0.02 2 0.02

> 600 2 0.02 2 0.02 2 0.02

1) Nominal capacity in litres/heating output; in the case of multi-

boiler systems, the smallest single heating output is to be used.

Caution.

The use of unsuitable heating water may

cause aluminium corrosion and a result-

ing lack of leak-tightness.

In contrast to steel, grey cast iron or copper,

for example, aluminium reacts with alkaline

heating water (pH value > 8.5) to produce

substantial corrosion.

▶ When using aluminium, make sure that

the pH value of the heating water is

between 6.5 and a maximum of 8.5.

Caution.

Risk of material damage if the heating

water is treated with unsuitable additives.

Unsuitable additives may cause changes in

the components, noises in heating mode and

possibly subsequent damage.

▶ Do not use any unsuitable frost and cor-

rosion protection agents, biocides or seal-

ants.

No incompatibility with our products has been detected to

date with proper use of the following additives.

▶ When using additives, follow the manufacturer's instruc-

tions without exception.

We accept no liability for the compatibility of any additive or

its effectiveness in the rest of the heating system.

Additives for cleaning measures (subsequent

flushing required)

– Adey MC3+

– Adey MC5

– Fernox F3

– Sentinel X 300

– Sentinel X 400

Additives intended to remain permanently in the

installation

– Adey MC1+

– Fernox F1

– Fernox F2

– Sentinel X 100

– Sentinel X 200

Additives for frost protection intended to remain

permanently in the installation

– Adey MC ZERO

– Fernox Antifreeze Alphi 11

– Sentinel X 500

▶ If you have used the above-mentioned additives, inform

the end user about the measures that are required.

▶ Inform the end user about the measures required for frost

protection.

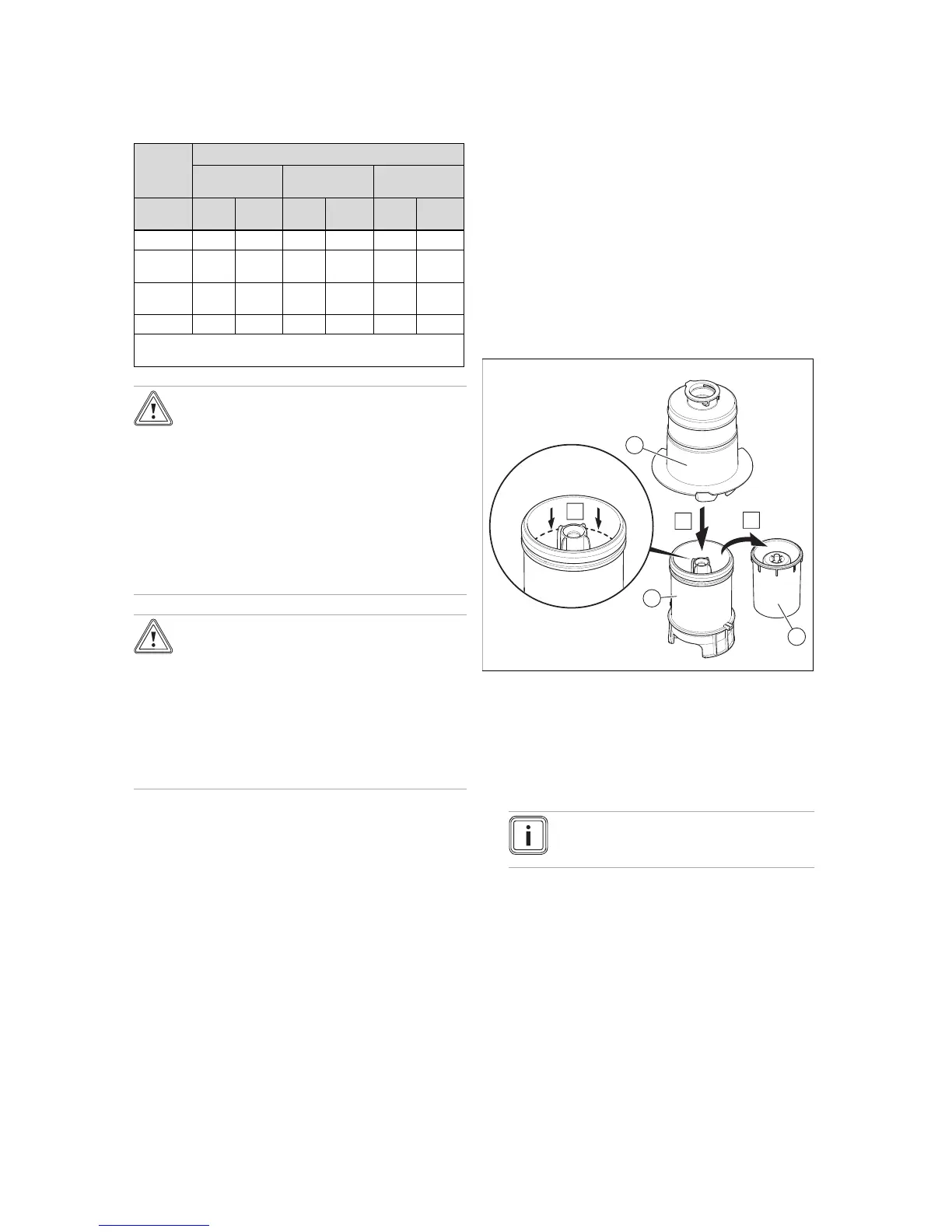

7.5 Filling the condensate trap

1. Unclip the lower section of the condensate trap (1) from

the upper section of the condensate trap (2).

2. Remove the float (3).

3. Fill the lower section of the condensate trap with water

up to 10 mm below the upper edge of the condensate

discharge pipe.

4. Re-insert the float (3).

Note

Check whether the float is present in the

condensate trap.

5. Clip the lower section of the condensate trap (1) into the

upper section of the condensate trap (2).

Loading...

Loading...