Maintenance

22 309550ZAP

Maintenance

Preventative Maintenance

Supplied Tool Kit

• Hex nut driver, 5/16

• Screwdriver, 1/8 blade

• Nozzle drill bit. Various sizes depending on nozzle

size.

• Impingement port drill bit, various sizes depending

on port size. See TABLE 1, page 23.

• 117661 pin vise, dual reversible chucks

• 551189 grease gun, with 3 oz grease

• 15B817 flush manifold (not included with spatter

spray gun).

Clean Gun Surface

Keep gun clean with accessory gun cover.

Applying a light coat of lubricant will make cleaning

easier.

Wipe off outside of gun with compatible solvent.

Use N Methyl Pyrrolidone (NMP), Dynaloy

®

-brand

Dynasolve CU-6, SB Versaflex-brand Dzolv

®

, or

equivalent to soften cured material.

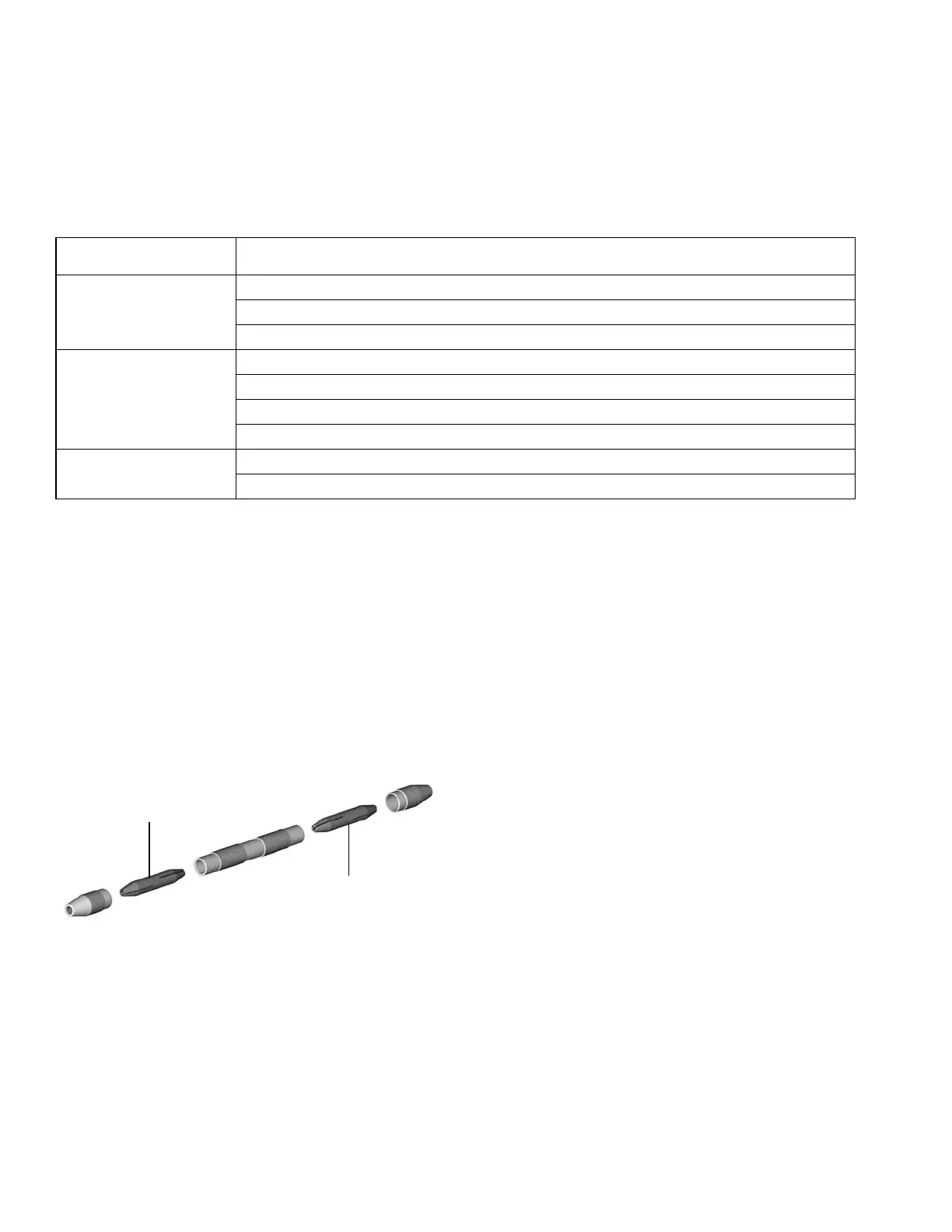

Recommended

Schedule

Maintenance Procedure

Daily

Flush Gun, page 20.

Clean Mix Chamber Nozzle, page 23.

Clean Air Cap, page 23

Weekly

Inspect the Mix Chamber and Side Seal Cartridges, page 24. Check o-rings.

Inspect the Check Valves, page 26. Check o-rings and filters.

Inspect the Piston Safety Lock, page 26.

Inspect the Check Valves, page 26.

As Needed

Clean Impingement Ports, page 23.

Lubrication, page 24

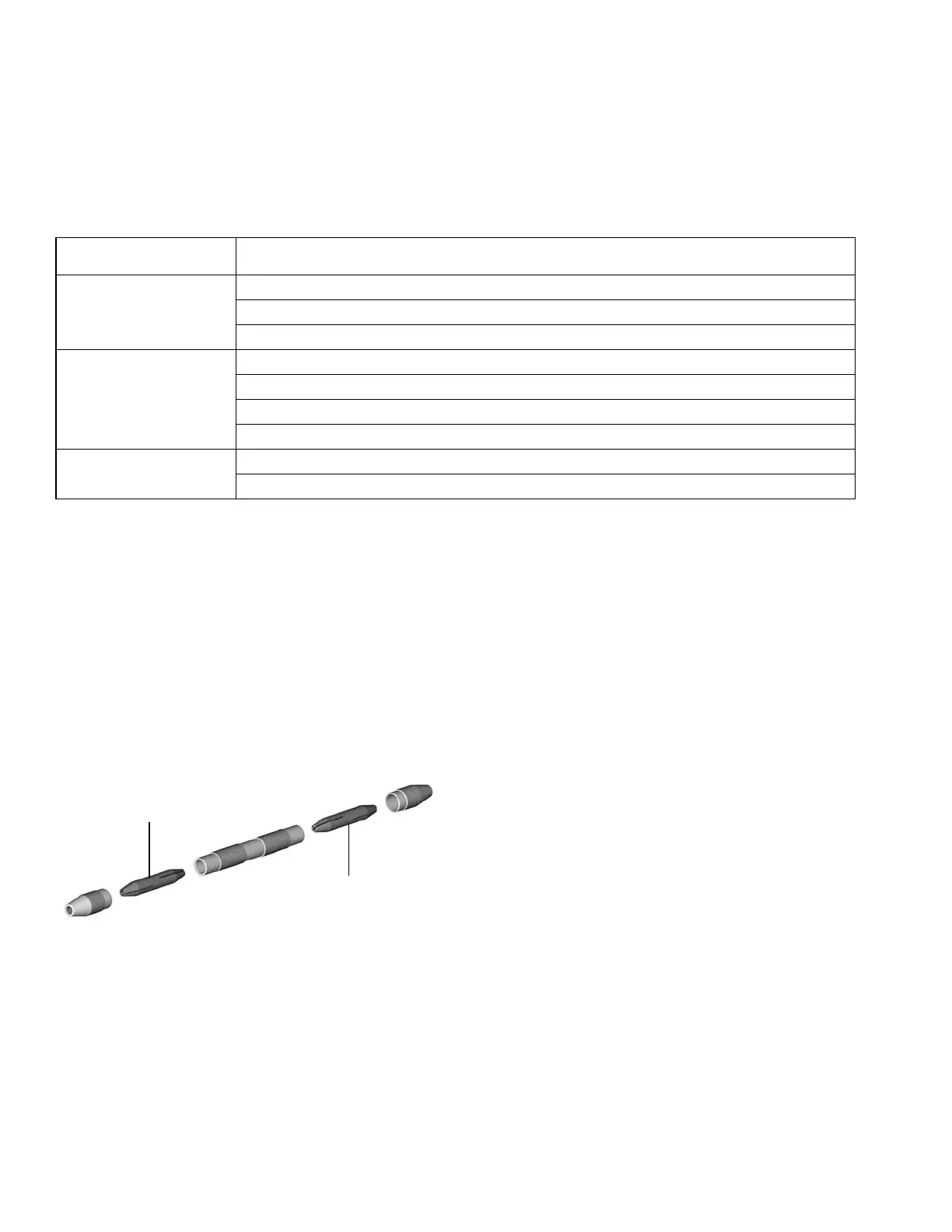

Reversible

Reversible

TI3864a

Loading...

Loading...