Maintenance

309550ZAP 23

Clean Mix Chamber Nozzle

1. Follow the Pressure Relief Procedure, page 19.

2. Engage the piston safety lock (L). See Piston

Safety Lock, page 20.

3. Use the appropriate size drill bit to clean mix

chamber nozzle (N). If necessary, clean air cap (C)

gently with stiff brush.

NOTE: Refer to TABLE 1, and Drill Bit Kits, page 39.

Clean Air Cap

Soak air cap in compatible solvent. Clean holes with #58

(0.042) drill bit.

Clean Impingement Ports

1. Follow the Pressure Relief Procedure, page 19.

2. Disconnect air line quick coupler (D) and remove

fluid manifold (M).

3. Follow the Flush Gun procedure, page 20. If the

gun will not flush, see Inspect the Mix Chamber

and Side Seal Cartridges, page 24.

4. Follow the Remove Front End procedure, page 29.

5. Push mix chamber (19) forward until impingement

ports (IP) are visible. Some mix chambers have

counterbored holes (CB) and require two drill sizes

to clean impingement ports completely. See TABLE

2, page 24, to select the appropriate drill bit size.

Also see Drill Bit Kits, page 39.

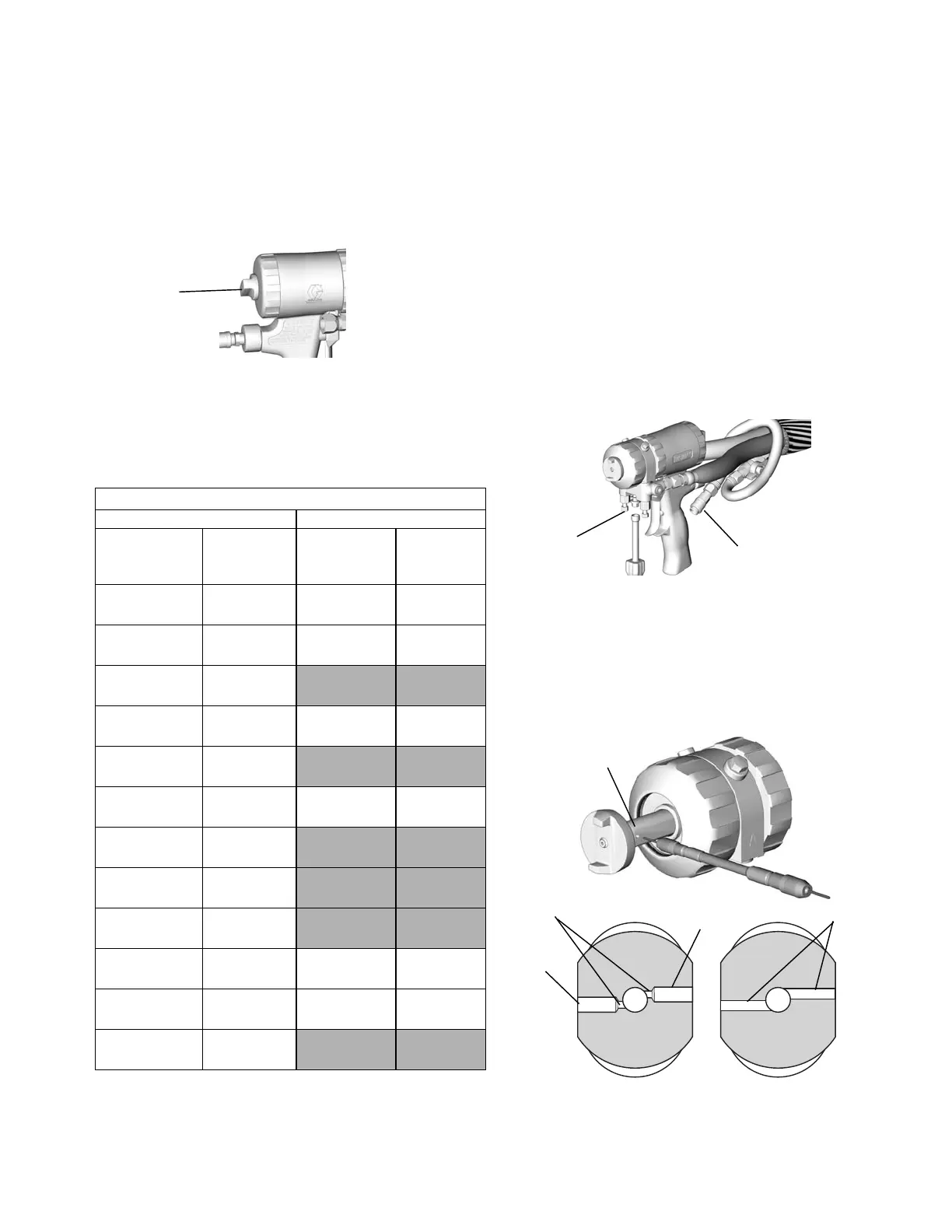

Table 1: Nozzle Drill Bit Sizes

Round Spray Flat Spray

Mix Chamber

Part Number

Drill Size

in. (mm)

Mix

Chamber

Part Number

Drill Size

in. (mm)

AR2020

#58, 0.042

(1.00)

AF2020

3/32, 0.094

(2.35)

AR2929

#55, 0.052

(1.30)

AF2929

3/32, 0.094

(2.35)

AR3737

#55, 0.052

(1.30)

AR4242

#53, 0.060

(1.50)

AF4242

3/32, 0.094

(2.35)

AR4747

1/16, 0.0625

(1.59)

AR5252

#50, 0.070

(1.75)

AF5252

3/32, 0.094

(2.35)

AR6060

#44, 0.086

(2.15)

AR7070

3/32, 0.094

(2.35)

AR8686

#32, 0.116

(2.90)

AR2237

0.47 (1.2)

AF2033

3/32, 0.094

(2.35)

AR2924

#55, 0.052

(1.30)

AF2942

3/32, 0.094

(2.35)

AR3729

#55, 0.052

(1.3 mm)

TI2409A

L

D

M

TI2554A

IP

CB

IP

CB

TI2420A

TI3533a

Mix Chambers AR and AF,

2020 and 2929

Mix Chambers AR and AF,

4242 or larger

19

Loading...

Loading...