Repair

26 312760A

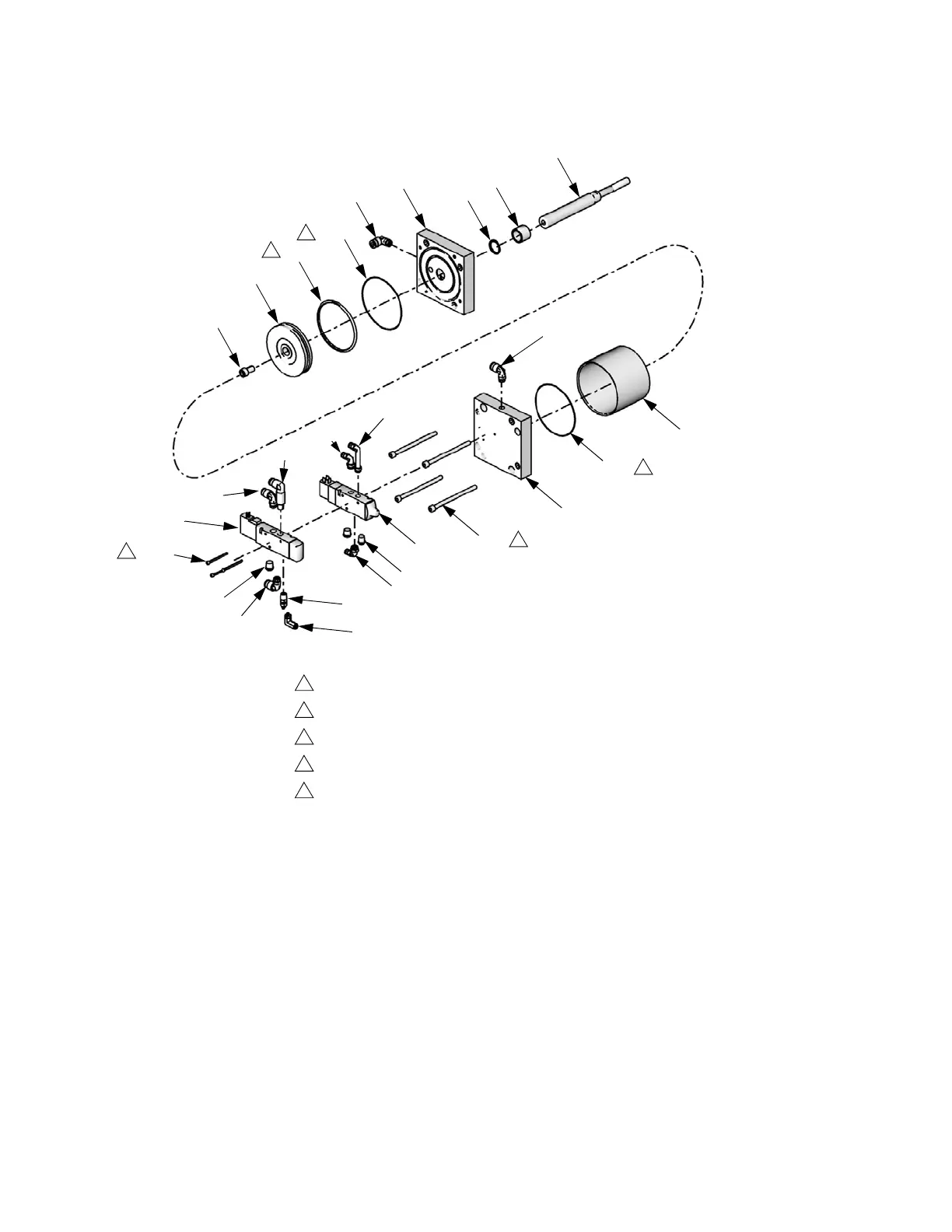

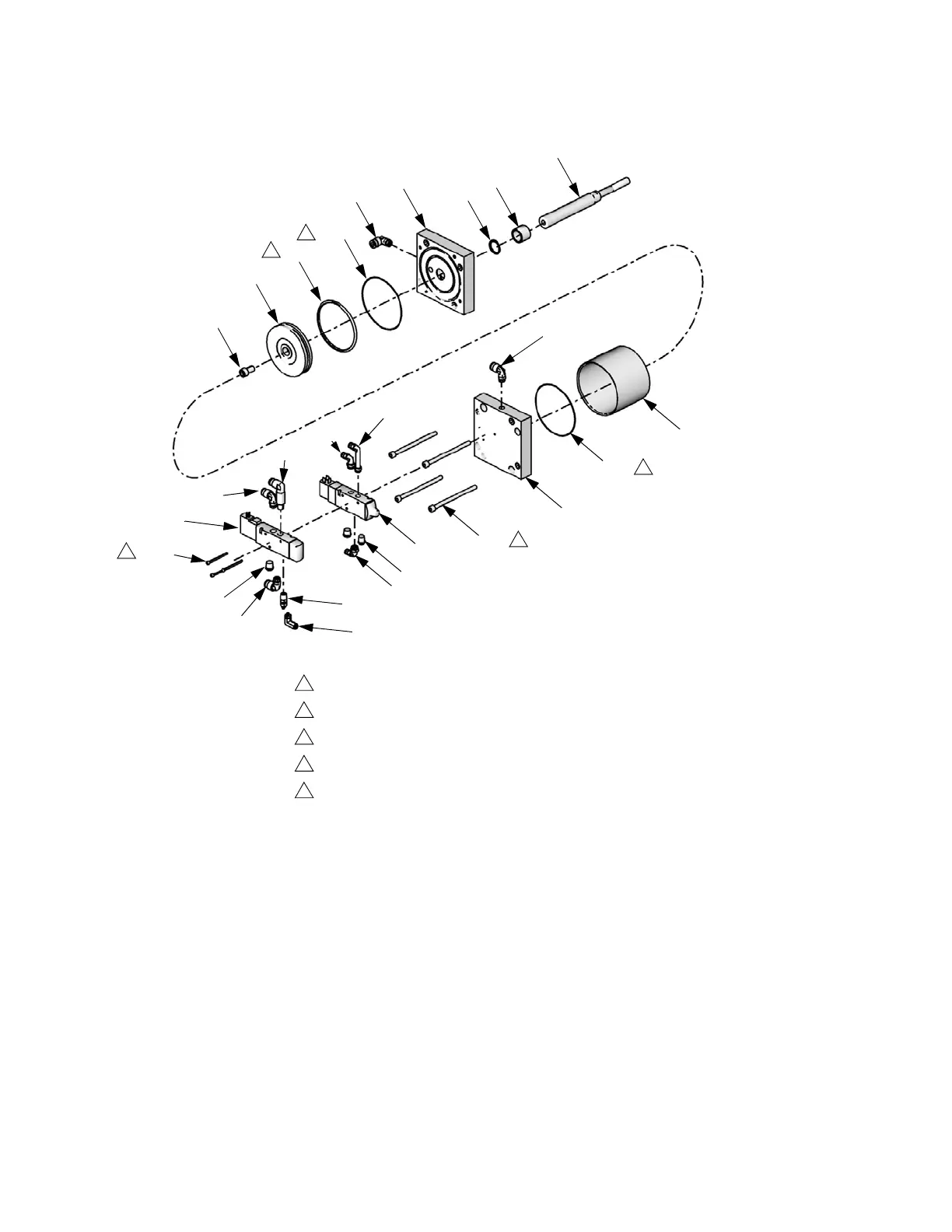

Air Cylinder Kit Installation

Prepare Machine for Kit Installation

1. Relieve pressure. See Pressure Relief Procedure,

page 13.

2. Shut down the machine. See Shutdown, page 13.

3. Disconnect the pressurized air input hose.

4. Remove shroud screws (2202, 2409). See F

IG. 11

on page 36 and F

IG. 15 on page 41.

5. Remove the shroud (117, 214). See F

IG. 10 on

page 34 and F

IG. 15 on page 41.

Disassemble the Air Cylinder

6. Remove the incoming power bracket (110) from the

machine by removing the two attachment

screws (109). See F

IG. 9 on page 33.

7. Remove the two solenoid valves (407, 408) from the

cylinder blind end block (418) by removing the three

socket head cap screws (402).

8. Use an open-end wrench to remove all hex

nuts (103, 100b, 100d) connecting the piston rod to

the drive block. See F

IG. 9 on page 33.

9. Remove the four screws (108) that attach the cylin-

der rod end block (417) to the frame. See F

IG. 9 on

page 33. Access the screws through the four holes

416

411

418

404

414

415

409

410

412

414

402

407

412

422

415

413

412

420

405

401

417

412

411

403

419

406

408

Torque to 41 in-lb (4.6 N•m).

Torque to 350 in-lb (39.5 N•m).

Torque to 100 ft-lb (135 N•m).

Coat all sliding surfaces with lubricant, part 115982.

Apply sealant tape to npt fittings.

1

2

3

4

5

2

1

4

4

4

ti12490a

Loading...

Loading...