Troubleshooting

312780K 19

NOTE: Refer to the Schematic Diagrams, page 32.

If the dispense or purge valves are not turning on or off correctly, it could be caused by one of the following.

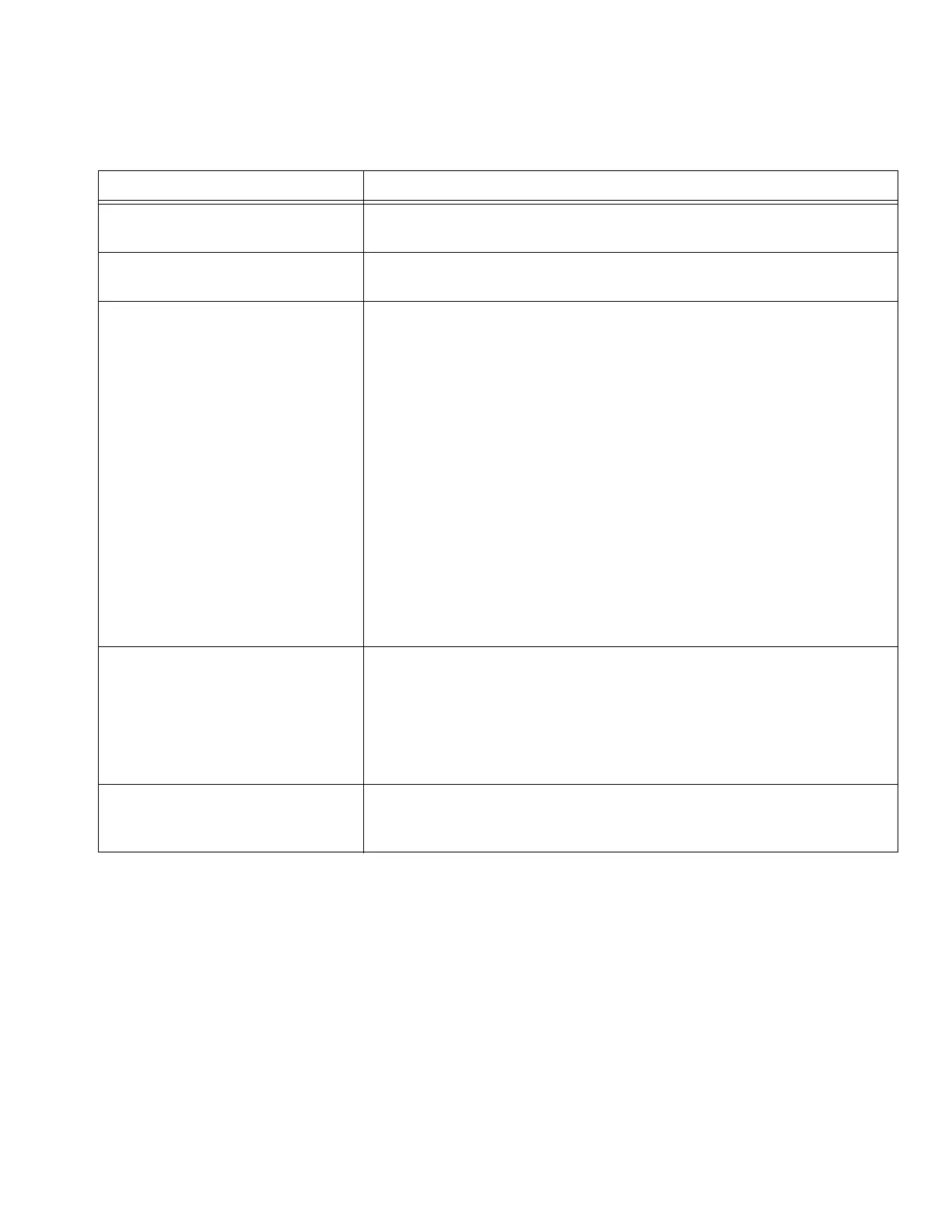

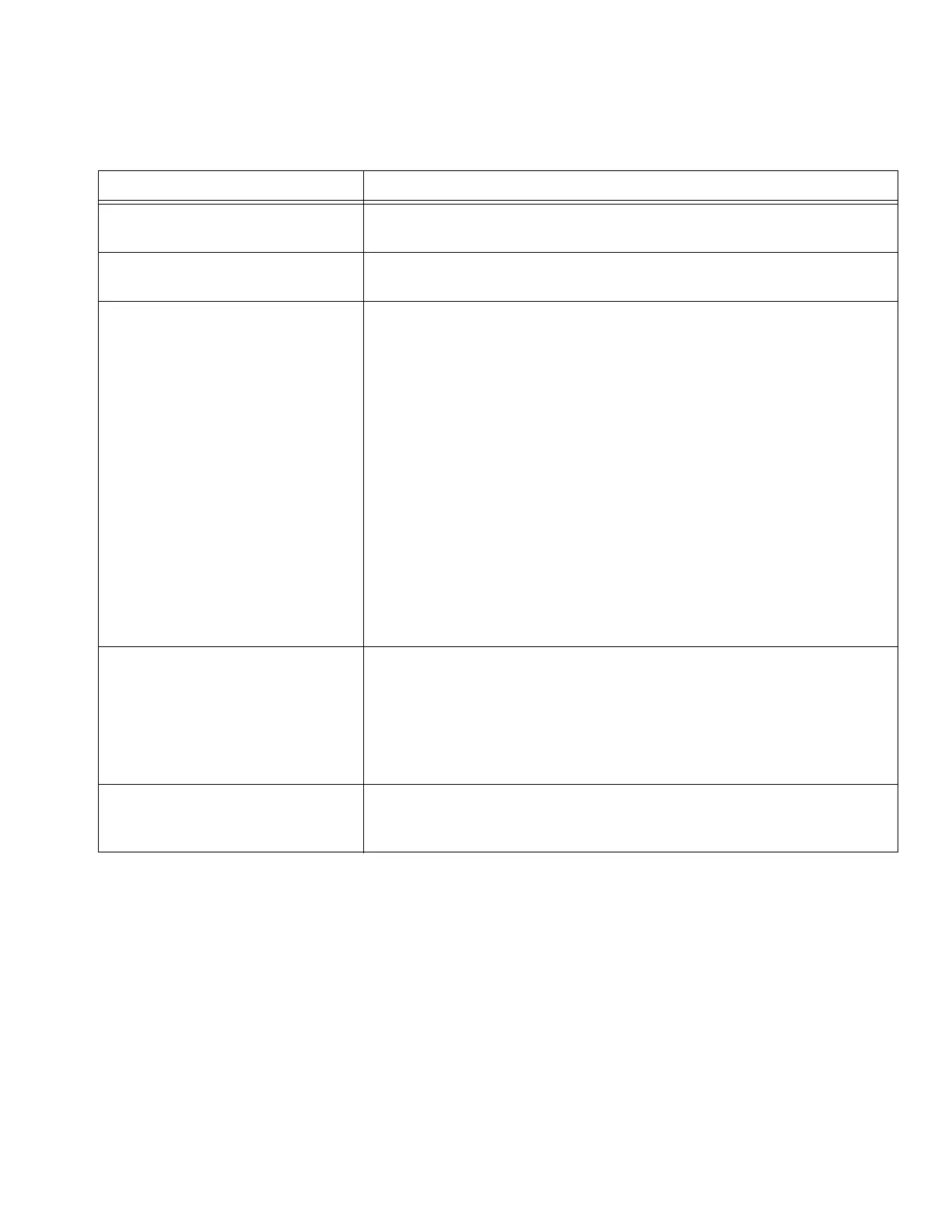

Cause Solution

1. Air regulator pressure set too

high or too low.

Check air pressure. 80-90 psi (550-630 kPa, 5.5-6.3 bar) is commonly used.

Do not go below 70 psi (490 kPa, 4.9 bar) or above 120 psi (0.8 MPa, 8 bar).

2. Air or electrical lines damaged or

connections loose.

Visually inspect air and electrical lines for kinks, damage, or loose connec-

tions. Service or replace as needed.

3. Solenoid failure Manually operate the valves by removing the Fluid Station cover and press-

ing and releasing solenoid valve override buttons. F

IG. 5.

Use the control board diagnostics to check the signals. If signals do not

occur correctly, go to Cause 4.

Valves should snap open and shut quickly. If the valves actuate slowly, it

could be caused by:

• Air pressure to the valve actuators is too low. See Cause 1.

• Solenoid is clogged. Make sure air supply has 5 micron filter installed.

• Something is restricting the solenoid or tubing. Check for air output from

air line for corresponding solenoid when valve is actuated. Clear restric-

tion.

• A dose valve is turned in too far. See ProMix 2KS Operation manual for

settings.

• Fluid pressure is high and air pressure is low.

• Fluid seal in valve has failed. See corresponding valve manual for repair

information.

4. Solenoid, cable, or fluid station

control board failure.

Check voltage level to solenoid by pulling solenoid connector and checking

voltage between pins.

If voltage is 9-15 VDC, the solenoid is damaged. Replace solenoid or correct

electrical line problem.

If there is no voltage, replace the board.

5. Blown fuse. Check condition of fuses F1 and F2. F1 powers J9 and J14 (Dose Valve A

and B and Purge Valve A and B solenoids). F2 powers J8 and J15 (3rd

Purge Valve, Dump Valve A and B, and GFB 1 and 2 solenoids).

Loading...

Loading...