Repair

Repair Repair

Repair

Repairingthisequipmentrequiresaccesstoparts

thatmaycauseelectricshockorotherseriousinjury

ifworkisnotperformedproperly.Besuretoshut

offallpowertoequipmentbeforerepairing.

Before Before

Before

Beginning Beginning

Beginning

Repair Repair

Repair

NOTICE NOTICE

NOTICE

Propersystemsetup,startup,andshutdown

proceduresarecriticaltoelectricalequipment

reliability.Thefollowingproceduresensuresteady

voltage.Failuretofollowtheseprocedureswill

causevoltageuctuationsthatcandamage

electricalequipmentandvoidthewarranty.

1.Flushifnecessary.SeeFlushing,page50.

2.SeeShutdown,page49.

Repair Repair

Repair

Proportioning Proportioning

Proportioning

Pumps Pumps

Pumps

1.FollowBeforeBeginningRepair,page51.

2.TurnbothPressureRelief/Sprayvalve(SA,SB)

toPressureRelif/Circulation.Routeuidtowaste

containersorsupplytanks.Ensuregauges(GA,

GB)dropto0psi.

Note

Usedropclothorragstoprotectthe

Reactorandsurroundingareafromspills.

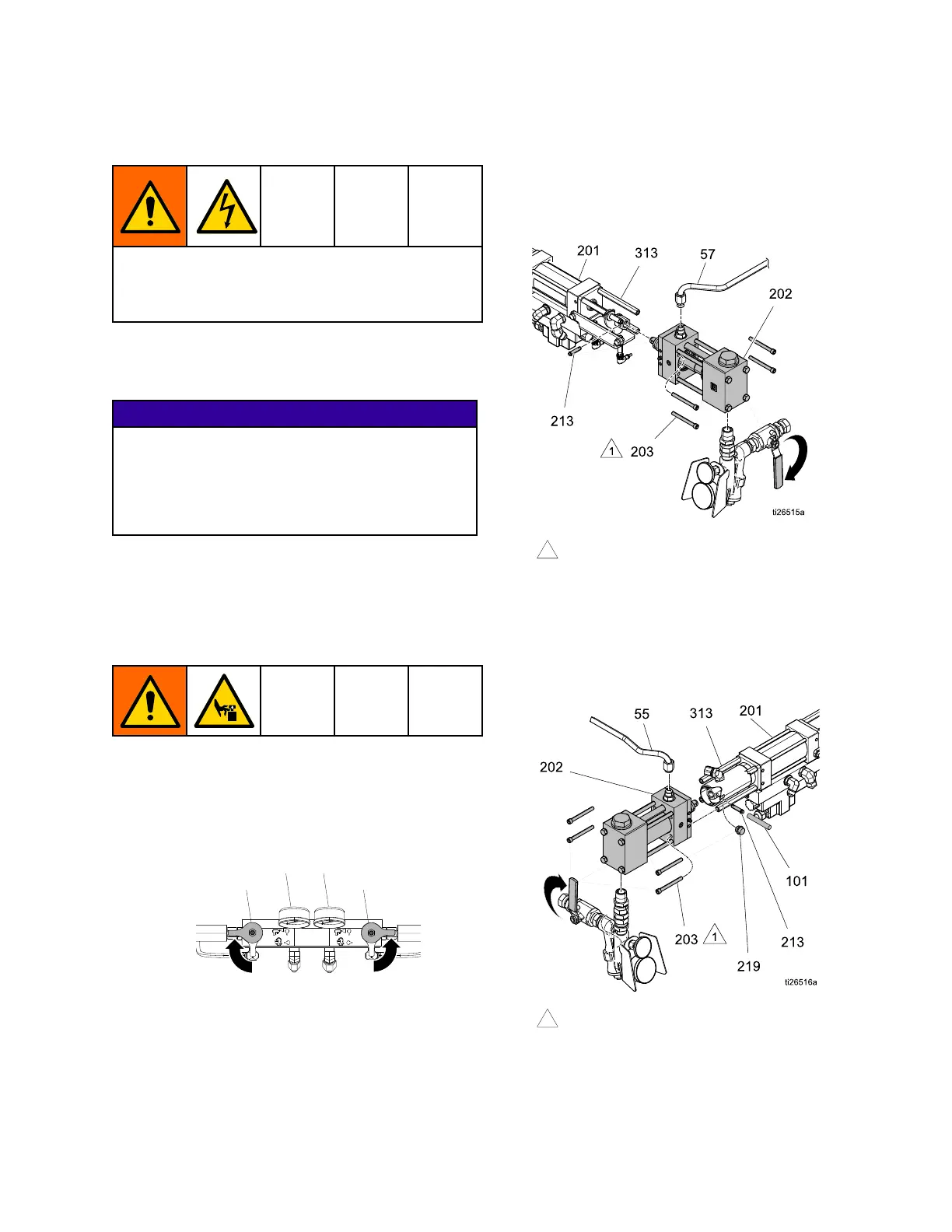

3.DisconnecttheB(Resin)sidepumpinletline,the

inlety-strainer,andhardtube(57).Removethe

pin(213)fromtheclevis(317)todisconnectthe

pumpfromthehydrauliccylinder(201).Remove

thefourscrews(203)holdingthepumptothe

spacers(313)ofthecylinder.Takethepump

assemblytoaworkbench.

Torque to 200 in. - lb (22.6 N•m).

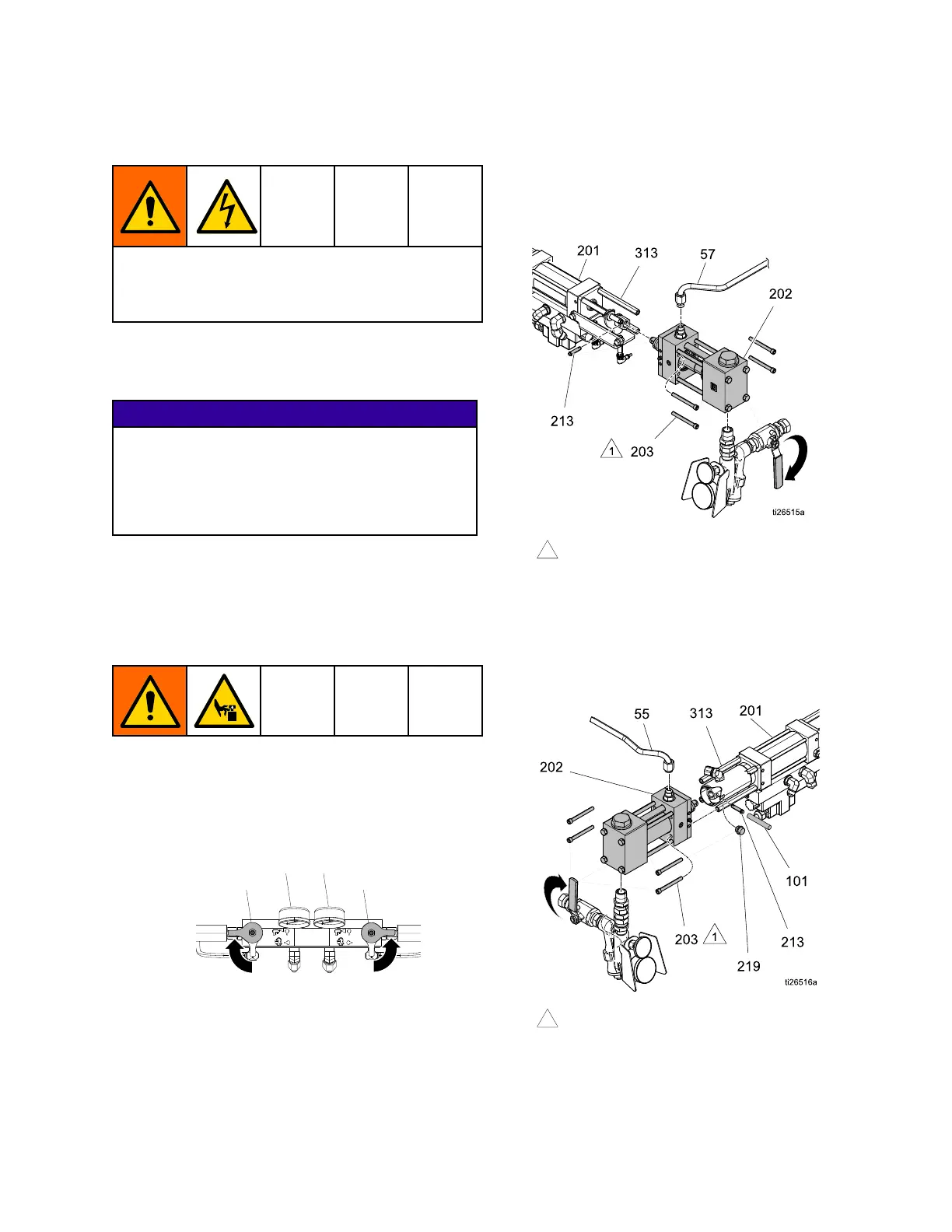

4.DisconnecttheA(ISO)sidepumpinletline,the

inlety-strainer,andhardtube(55).Usethepin

extractortool(101)toremovethepin(213),which

disconnectsthepumpfromthehydrauliccylinder

(201).Removethefourscrews(203)holdingthe

pumptothespacers(313)ofthecylinder.Take

thepumpassemblytoaworkbench.

Torque to 200 in. - lb (22.6 N•m).

5.Seepumpmanualforrepairinstructions.

6.Reconnectthepumpinthereverseorder.Torque

thescrewsto200in.-lb(22.6N•m)

334946C 51

Loading...

Loading...