Model T33903/T33904 (Mfd. Since 07/23)

-39-

Operation

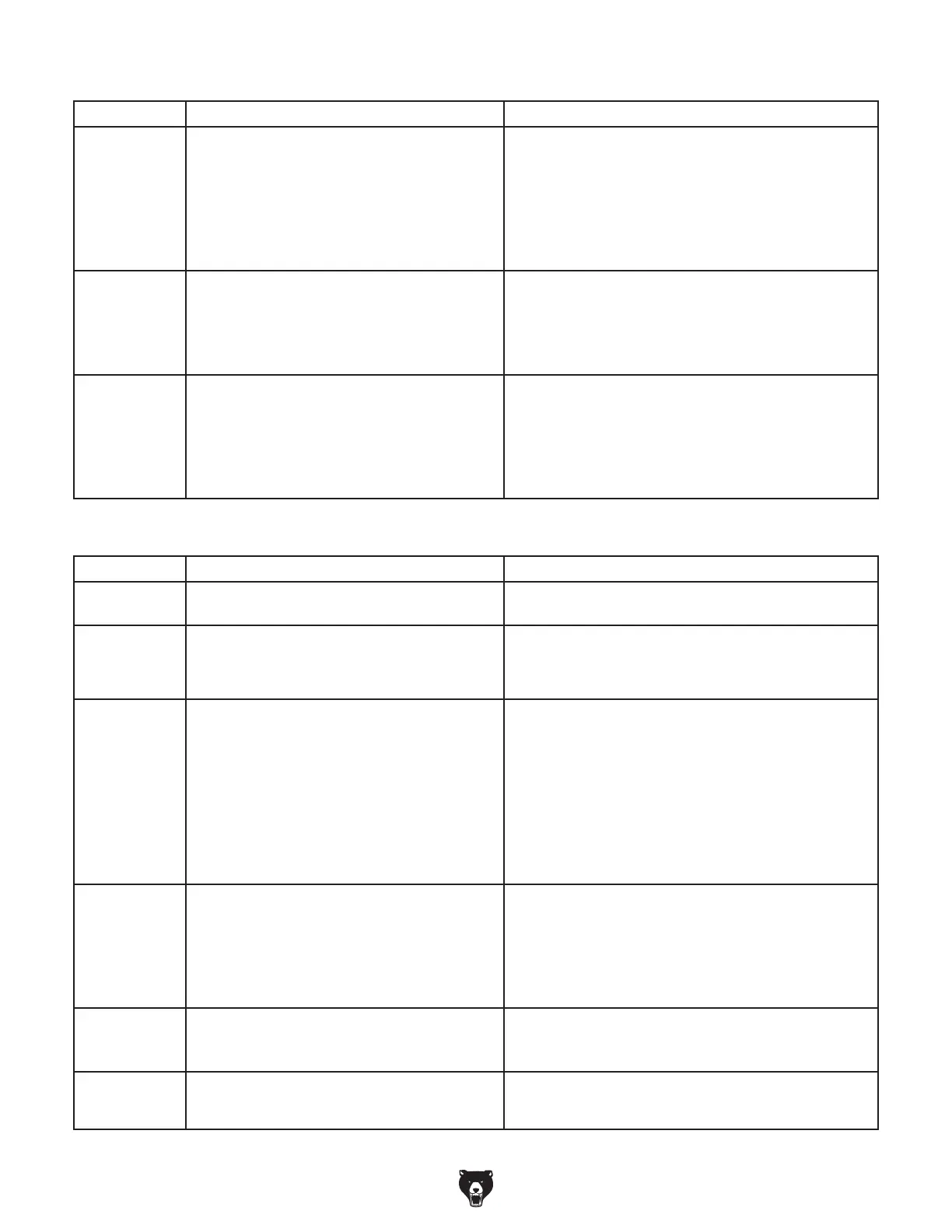

Symptom Possible Cause Possible Solution

Tool falls out or

loose in chuck.

1. Chuck jaws loose.

2. Excessive feed pressure.

1. Tighten chuck jaws.

2. Decrease feed pressure and allow chips to clear.

Chuck and

arbor fall out

or loose in

spindle.

1. Debris on chuck, arbor, or in spindle taper.

2. Excessive feed pressure.

1. Clean chuck, arbor, and spindle taper, then re-install

(Page 22).

2. Decrease feed pressure and allow chips to clear.

Breaking tools

or cutters.

1. Spindle speed/feed rate too fast.

2. Taking too big of cut at one time.

3. Improper cutting technique or type of cut for

tool/machine.

4. Cutting tool too small.

5. Cutting tool getting too hot.

6. Spindle extended too far down during or at

beginning of operation.

1. Reduce spindle speed (Page 29); reduce feed rate.

2. Decrease feed pressure and allow chips to clear.

3. Use right technique, tool, or machine for job.

4. Use larger cutting tool and slower feed rate.

5. Use coolant or oil for appropriate application; reduce

cutting speed (Page 29).

6. Fully retract spindle and raise table to increase rigidity.

Workpiece or

tool vibrates or

chatters during

operation.

1. Spindle extended too far down during or at

beginning of operation.

2. Table lock handles not tight.

3. Workpiece not secure.

4. Spindle speed/feed rate too fast.

5. Quill shaft lock screw not adjusted correctly.

1. Fully retract spindle and raise table to increase rigidity.

2. Tighten table lock handles (Page 32).

3. Properly clamp workpiece on table or in vise.

4. Reduce spindle speed (Page 29); reduce feed rate.

5. Adjust quill shaft lock screw (Page 46).

Table hard to

move.

1. Table locked.

2. Dirty or dry rack and pinion.

1. Disengage table locks (Page 32).

2. Clean away chips/debris. Lubricate rack and pinion

(Page 37).

Backside of

workpiece

splinters.

1. Scrap board not installed between table and

workpiece.

1. Install scrap board between table and workpiece.

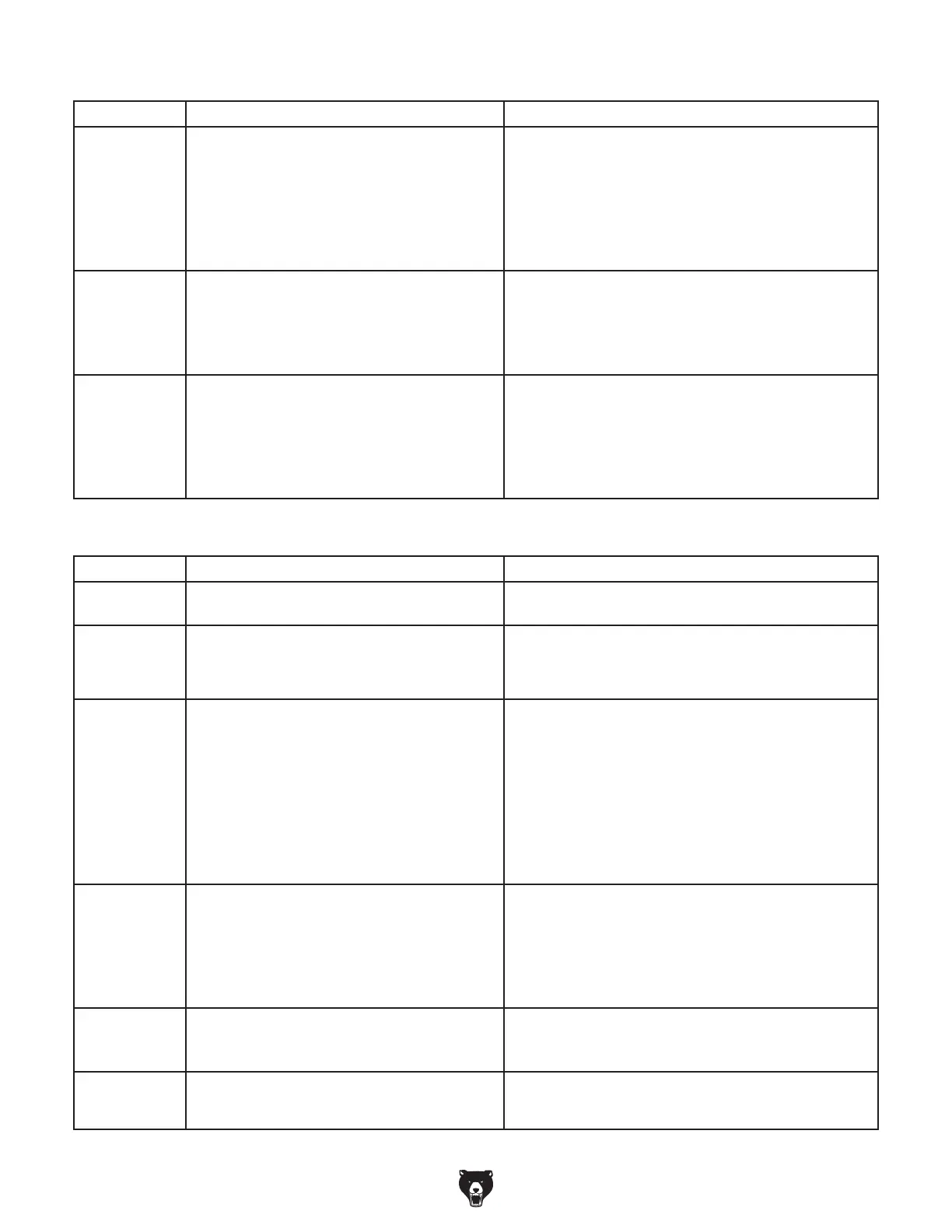

Symptom Possible Cause Possible Solution

Machine has

vibration or

noisy operation.

7. Chuck or cutter at fault.

8. Motor fan rubbing on fan cover.

9. Spindle bearings at fault.

10. Centrifugal switch needs adjustment/at fault.

11. Motor bearings at fault.

7. Replace out-of-round chuck, dull, or bent cutter.

8. Fix/replace fan cover; replace loose/damaged fan.

9. Test by rotating spindle; rotational grinding/loose shaft

requires bearing replacement.

10. Adjust/replace if at fault.

11. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

LED does not

illuminate.

1. Lens covered with dust.

2. Wiring broken, disconnected, or corroded.

3. LED or LED driver damaged/at fault.

4. LED switch at fault.

1. Clean lens.

2. Fix broken wires or disconnected/corroded

connections (Page 47).

3. Replace LED or driver (Page 44).

4. Replace switch.

Laser guide

does not

illuminate.

1. Lens covered with dust.

2. Wiring broken, disconnected, or corroded.

3. Laser module(s) damaged/at fault.

4. Laser switch at fault.

5. Laser LED driver at fault.

1. Clean lens.

2. Fix broken wires or disconnected/corroded

connections (Page 47).

3. Replace lase module(s) (Page 44).

4. Replace switch.

5. Replace laser LED driver.

Motor & Electrical (Cont.)

Loading...

Loading...