Model T33903/T33904 (Mfd. Since 07/23)

-37-

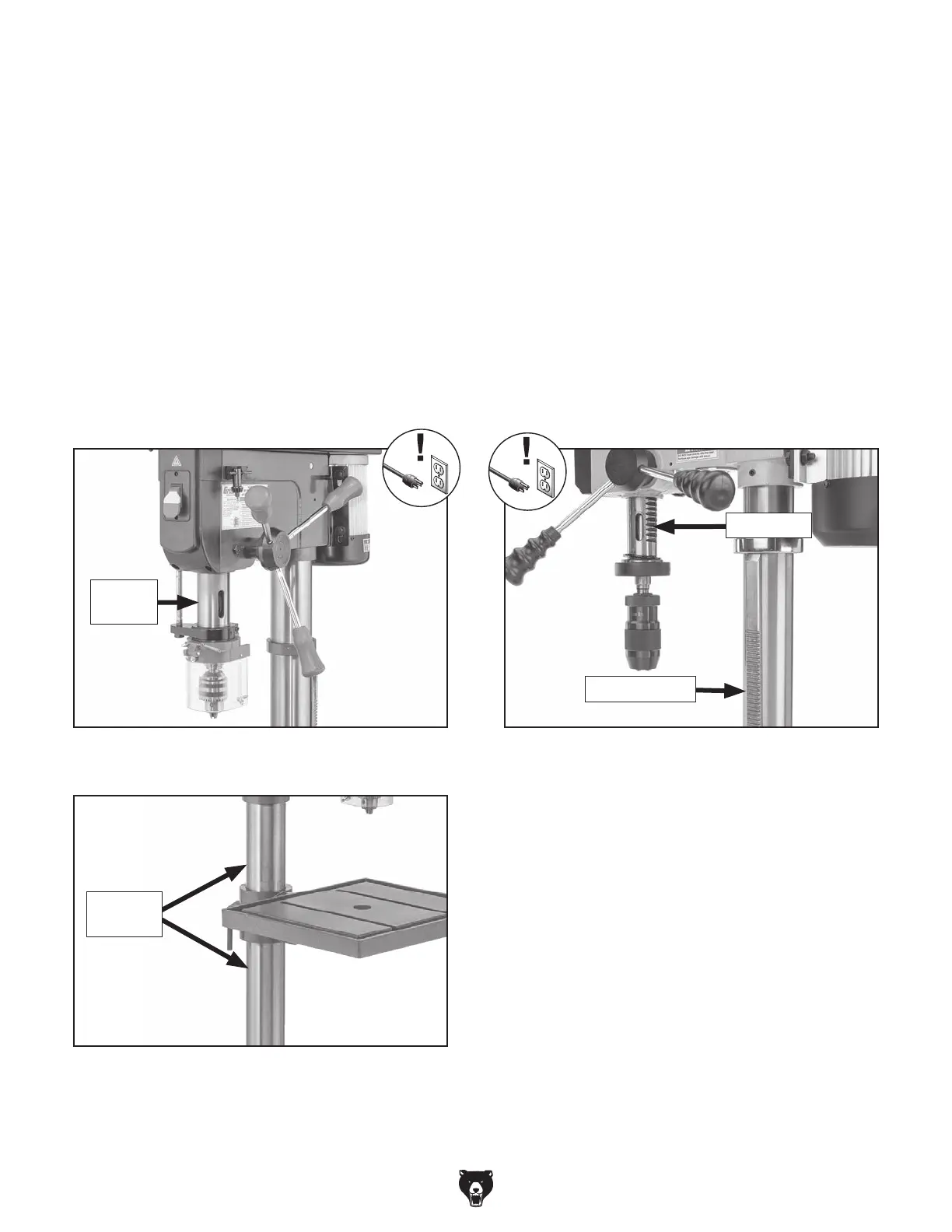

Figure 54. Spindle moved down to expose quill

surface.

Quill

Surface

Quill & Column Surfaces

Oil Type .... Grizzly SB1365 or ISO 68 Equivalent

Oil Amount

............................................Thin Coat

Lubrication Frequency

...........8 Hrs. of Operation

After cleaning, allow mineral spirits to dry, then

apply a thin coat of oil to the surfaces.

Items Needed Qty

Mineral Spirits .................................... As Needed

Shop Rags

......................................... As Needed

Move the spindle all the way down to access

the smooth surfaces of the quill. Adjust the table

height as necessary to access the entire length of

the column (see Figures 54–55). Clean both with

mineral spirits and shop rags.

Note: Avoid removing the grease from the column

and quill racks during cleaning.

Items Needed Qty

Mineral Spirits .................................... As Needed

Shop Rags

......................................... As Needed

Stiff Brushes

...................................................... 2

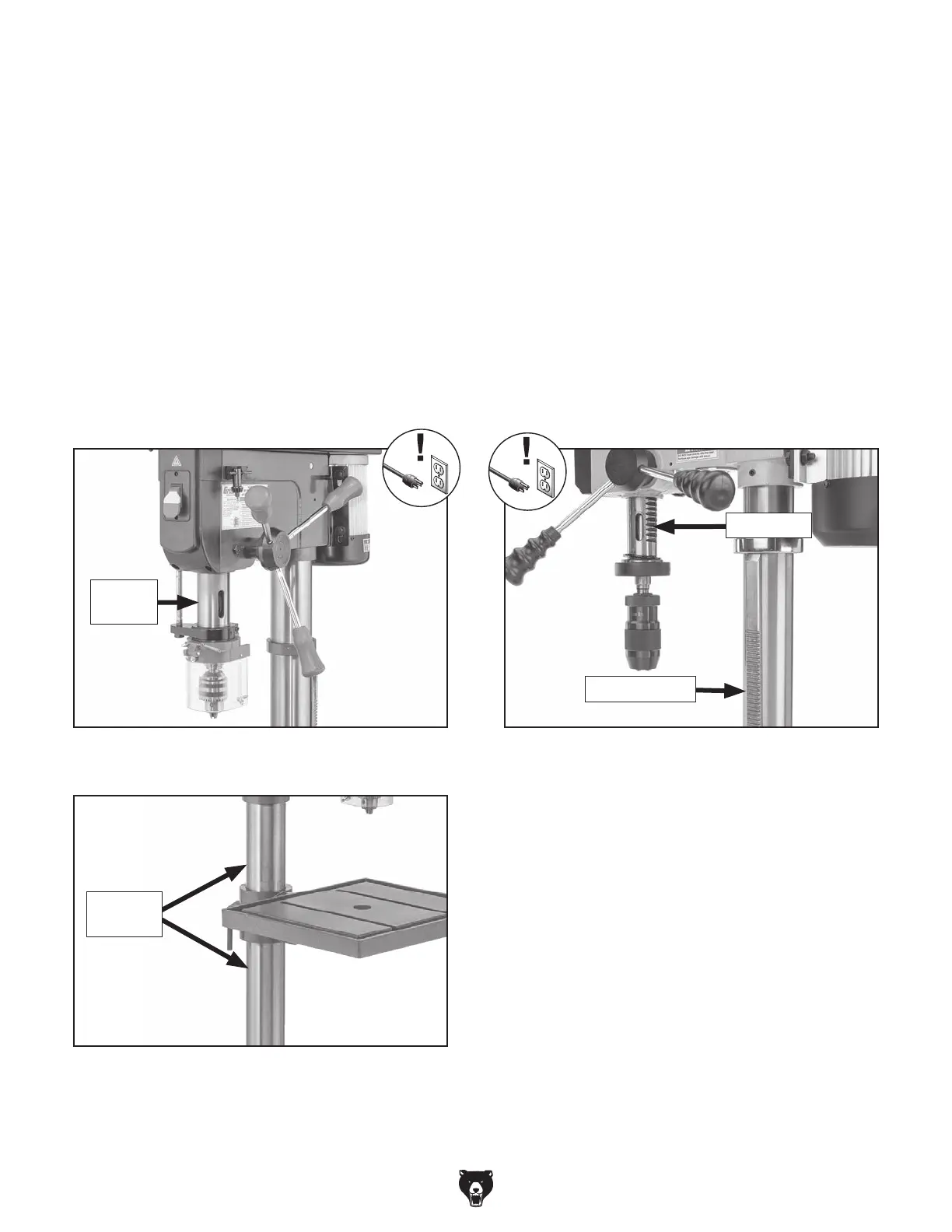

Figure 55. Column surface locations (T33904

shown).

Figure 56. Example of quill and column racks

exposed.

Allow mineral spirits to dry, then use a brush to

apply a thin coat of grease to the rack teeth, then

fully raise/lower the quill and table to distribute the

grease.

Column

Surfaces

Column Rack, Quill Rack & Pinion

Grease Type .... Grizzly T26419 or NLGI#2 Equiv.

Grease Amount

....................................Thin Coat

Lubrication Frequency

......... 90 hrs. of Operation

Move spindle all the way down to gain access to

quill rack (see Figure 56), then clean teeth with

mineral spirits, shop rags, and a brush.

Clean the column rack teeth (see Figure 56) in

a similar manner with mineral spirits, shop rags,

and a brush.

Quill Rack

Column Rack

Loading...

Loading...