Job __________________________

Designer ______________________

Contact _______________________

www.tekmarcontrols.com of 2 © 20 C 664 - 0/

0/

Snow Melting

Replaces: New

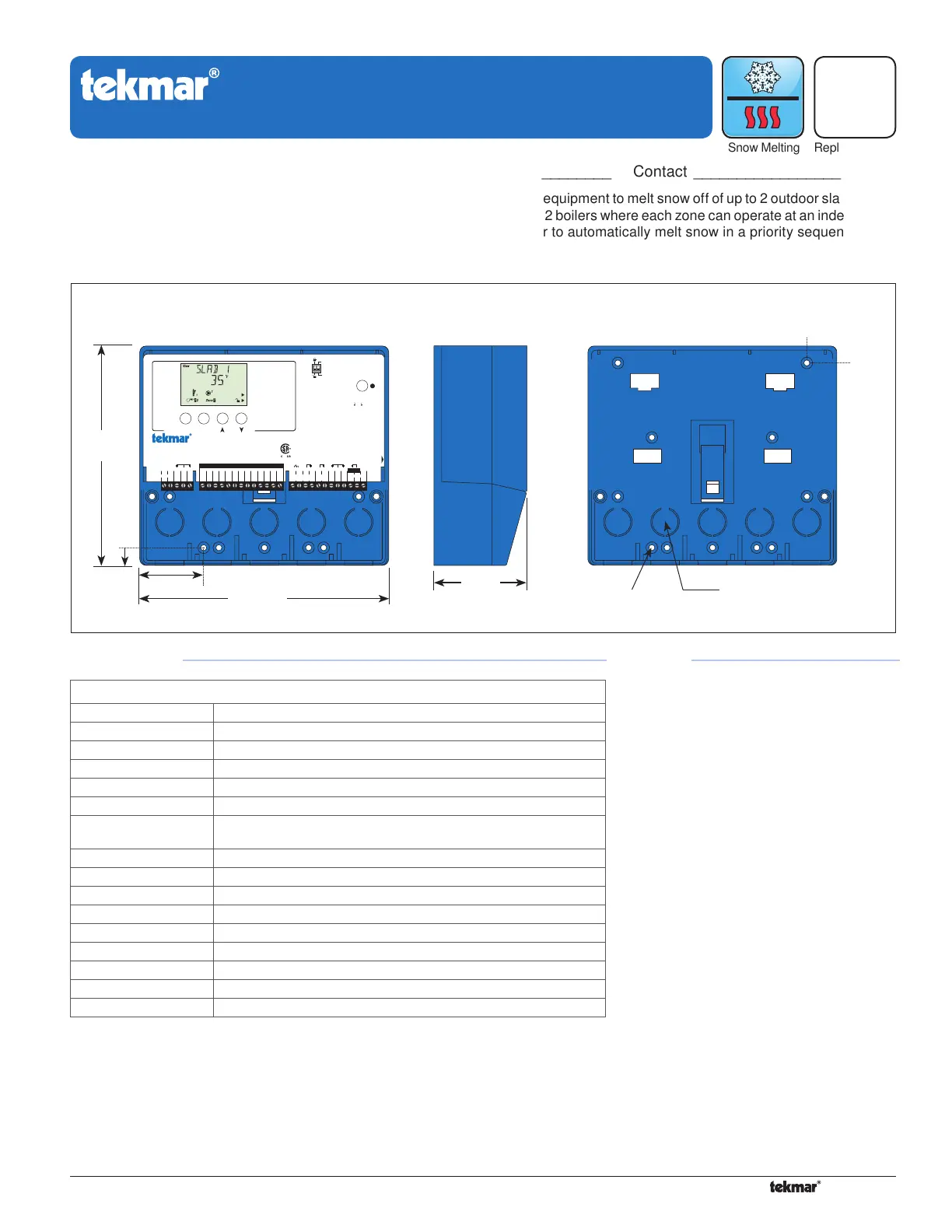

Front View

Side View

2–7/8”

(72 mm)

1/2” Knock-out

(x 5 back) (x 5 bottom)

Mounting Base

CL

1/2”

(13 mm)

7/8”

(23 mm)

6–5/8”

(170 mm)

7–5/8”

(193 mm)

1–7/8” (49 mm)

1/2”

(14 mm)

Ø 3/16” (5 mm)

--------------------------

Automatic snow detection and melt control

(with 090 Sensor)

Control up to 2 zones

Control up to 2 boilers

Slab temperature control

Mixing control (floating, variable speed, or

proportional)

Temporary Idle

Optional priority zoning operation

Slab protection for the snow melting system

Boiler Protection

Manual Override

Warm Weather Shut Down

Cold Weather Cut Out

Remote display and adjustment capabilities

Test sequence to ensure proper

component operation

Equipment Exercising

CSA C US certified (approved to applicable

UL standards)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-----------------------------------------------------

The Snow Detector & Melting Control 664 is designed to operate mechanical equipment to melt snow off of up to 2 outdoor slabs. It can

be used in hydronic snow melting applications consisting of up to 2 zones and 2 boilers where each zone can operate at an independent

temperature. This product uses a tekmar snow/ice detection sensor in order to automatically melt snow in a priority sequence while

protecting the boiler plant with a mixing device. It is capable of controlling up to 2 boilers, a variable speed or modulating (4-20 mA)

mixing device, a mix system pump, and 2 zone pumps.

An 090 Snow/Ice Sensor or Slab Sensor.

Two Zone, Two Stage Boiler, Mixing

Literature D664, A664, U664, D00, D070, E02

Control Microprocessor control. This is not a safety (limit) control

Packaged weight 3.5 lb. (600 g)

Dimensions 6-5/8” H x 7-9/6” W x 2-3/6” D (70 x 93 x 72 mm)

Enclosure Blue PVC plastic, NEMA type

Approvals CSA C US, meets class B: ICES & FCC Part 5

Ambient conditions

Indoor use only, 32 to 22°F (0 to 50°C), RH ≤90% Non-

condensing

Power supply 5 V (ac) ±0%, 50/60 Hz, 600 VA

Floating relays 230 V (ac) 5 A, /6 hp

Stage/Zn/P relays 230 V (ac) 5 A, /3 hp

Var. pump 230 V (ac) 2.4 A max (FLA) 5 A max (LRA), fuse T2.5 A 250 V

Demands 20 to 260 V (ac) 2 VA

Sensors NTC thermistor, 0 kΩ @ 77°F (25°C ±0.2°C) ß=3892

–Included Outdoor Sensor 070 and 3 of Universal Sensor 082

–Optional tekmar type #: 039, 040, 072, 073, 090, 09, 094, 74

Warranty Limited 3 Year (See D664 for full warranty)

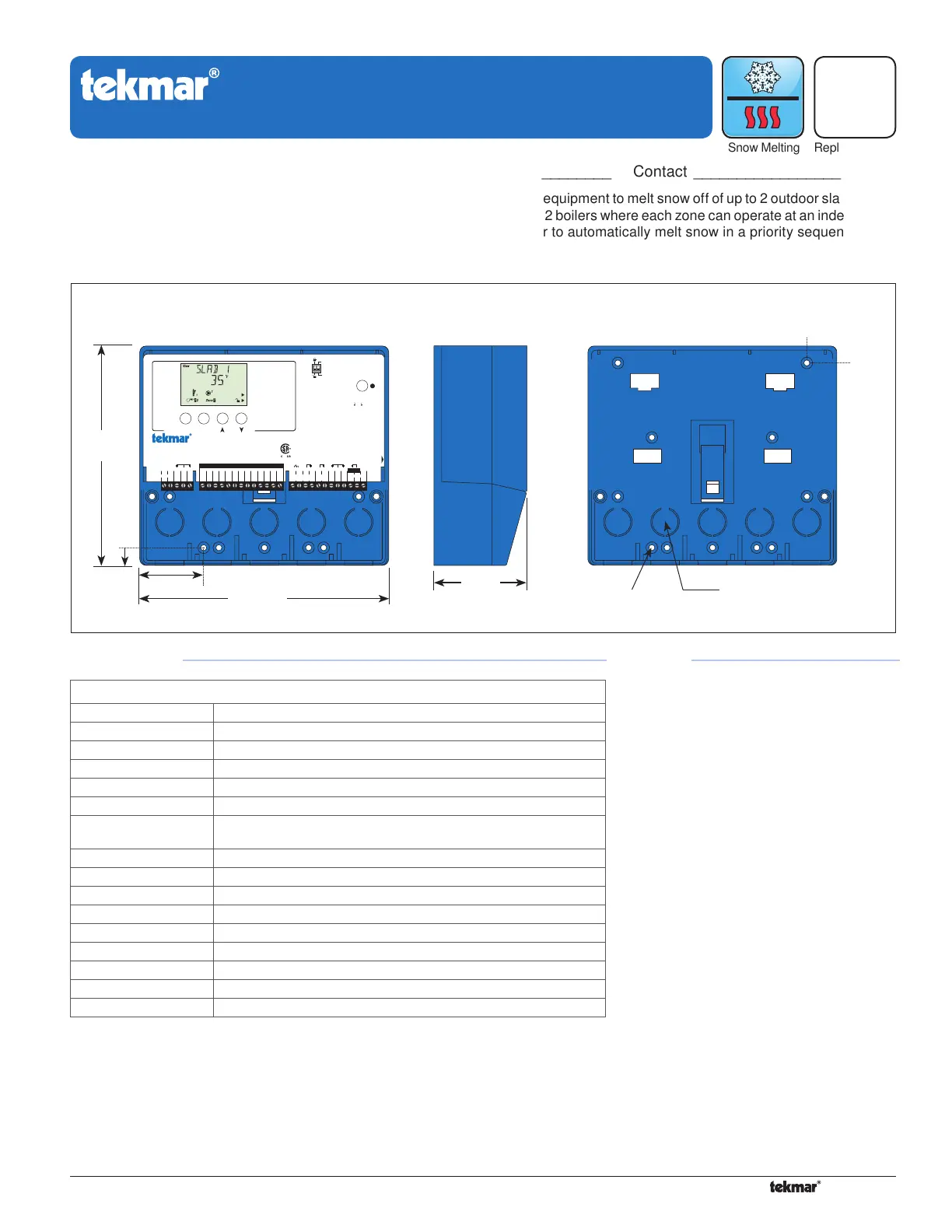

+

2

–

3

Opn/4-20 mA

Var

4

Pwr

Mix

5

Cls

6

Red

7

Blk/

Com

8

Blu

9

Yel

0

Brn/

Slab1

Slab

2

2

Com

3

tN2

4

Mix

Ret

5

Mix

Sup

6

Com

7

Boil

8

Out

9

Melt/Idle

Demand

20 2

Stage

1

22 23

Stage

2

24 25

Zn

1

26

Com

Zn

27

Zn

2

28 30

Sys

P1

29

Power

L N

Menu

Test

Two Zone, Two Stage Boiler, Mixing

Item

Start Stop

Idle Demand

Signal wiring must be rated at least 300

Melt Demand

not testing

testing

testing paused

For maximum heat,

press and hold Test

button for 3 seconds.

Made in Canada by

tekmar Control Systems Ltd.

tektra 900-0

Power 115 V ± 10% 50/60 Hz 600 VA

Floating Relays 230 V (ac) 5 A 1/6 hp

Stage/Zn/P1 Relays 230 V (ac) 5 A 1/3 hp

Var. Pump 230 V (ac) 2.4 A max (FLA)

5 A max (LRA), fuse T2.5 A 250V

Demand 20 to 260 V (ac) 2 VA

1 kΩ max

power

Date Code

H98D

Meets Class B:

Canadian ICES

FCC Part 5

Melt Demand

Idle Demand

WWSD

Minimum

Maximum

Water

Melting

ATC Contractor to coordinate with

Limbach and Snow melting system

vendor for additional monitoring

sensors, and install of all devices

and output to BMS.

Loading...

Loading...