Maintenance English

Plate Heat Exchanger 13

EN

EN

Finally the middle pair of bolts, and upper

and lower bolts are tightened.

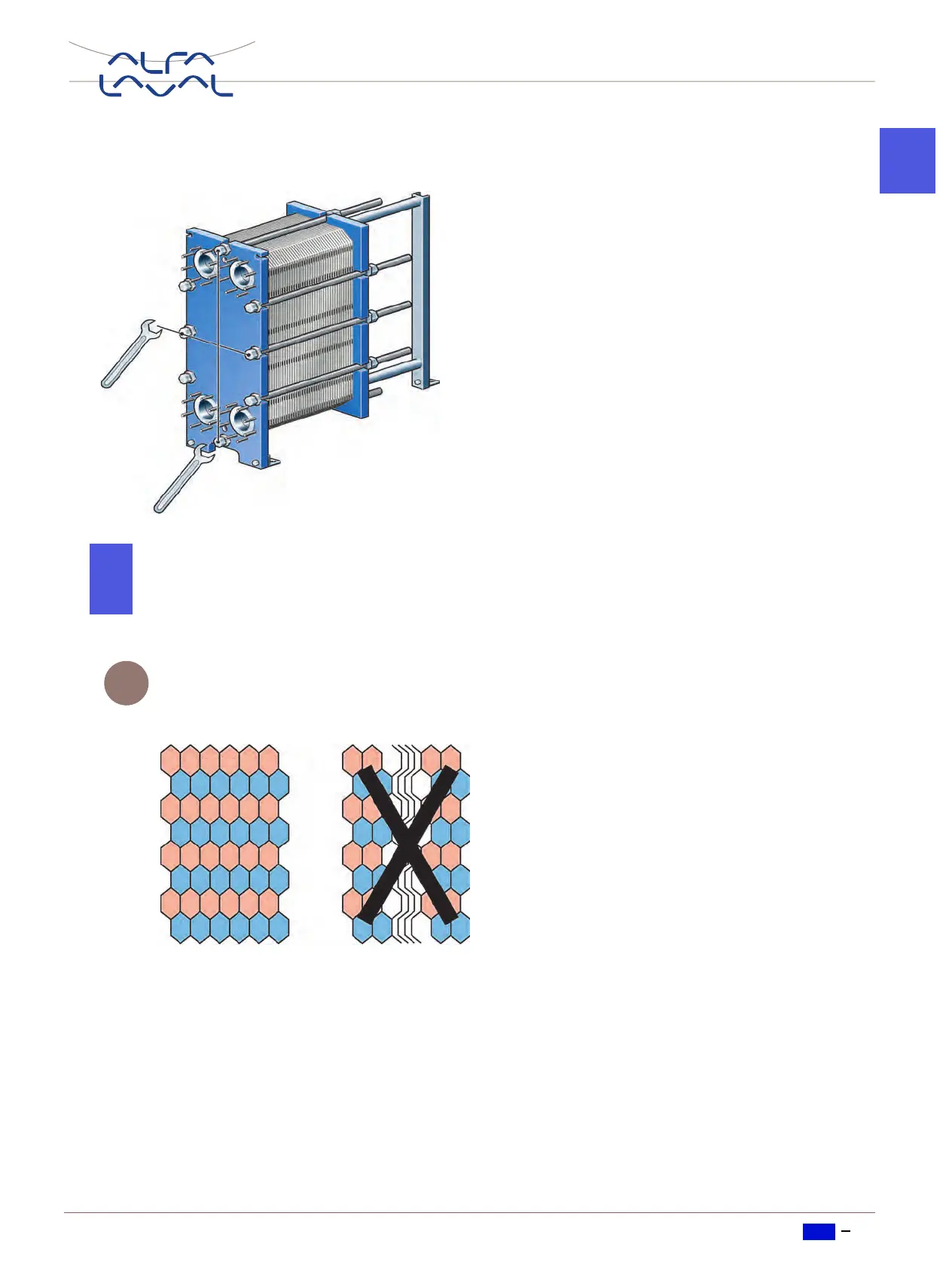

If the plates are correctly assembled, the

edges form a “honeycomb” pattern, see

picture below.

Pressure test after maintenance

Before start-up of production, whenever plates or

gaskets have been removed, inserted or exchanged,

it is strongly recommended to perform a pressure

test to confirm the internal and external sealing func-

tion of the PHE. At this test, one media side at the

time must be tested with the other side open to the

atmosphere.

The pressure testing shall be performed at a pres-

sure equal to the operating pressure of the actual unit

but never above the design pressure as stated on the

nameplate.

The recommended test time is 10 minutes.

Please note that PHE units for refrigeration applica-

tions and units with media not mixable with water

must be dried after hydrostatic pressure testing.

Please consult the local office/representative of the

supplier for advice on the pressure testing proce-

dure.

Note!

The actual measurement must never be less

than the A-dimension.

6

Loading...

Loading...