Description English

Plate Heat Exchanger 1

EN

EN

Description

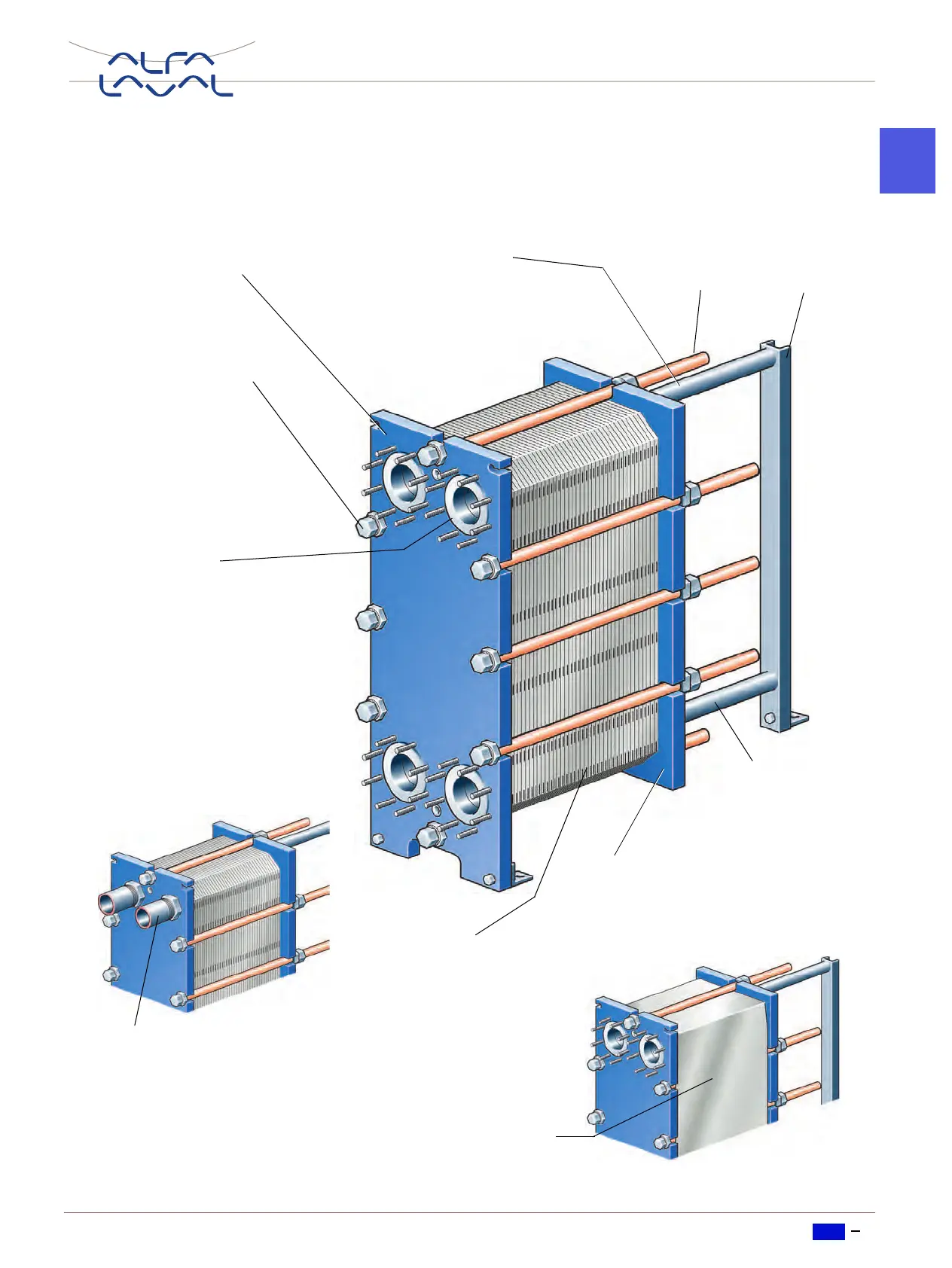

Main components

Support

column

Frame plate

Carrying bar

Carries the channel plates

and the pressure plate.

Connections

Holes through the frame plate,

permitting the media to enter into

the heat exchanger.

Threaded studs around the

holes secure the pipes to the ap-

paratus. Metallic or rubber-type

linings may be used to protect

the holes against corrosion.

Connections can also be pipes

for welding or threaded.

Tightening bolts

Press the channel

plates together.

Pressure plate

Moveable steel plate. In some cases

pipes may be connected to the pres-

sure plate.

Channel plates

Heat is transferred from one

medium to the other through

the thin channel plates.

The number of plates deter-

mines the total heat transfer

surface.

Guiding bar

Keeps the channel

plates in line at thei

lower end.

Bolt

protection

Pipe connections

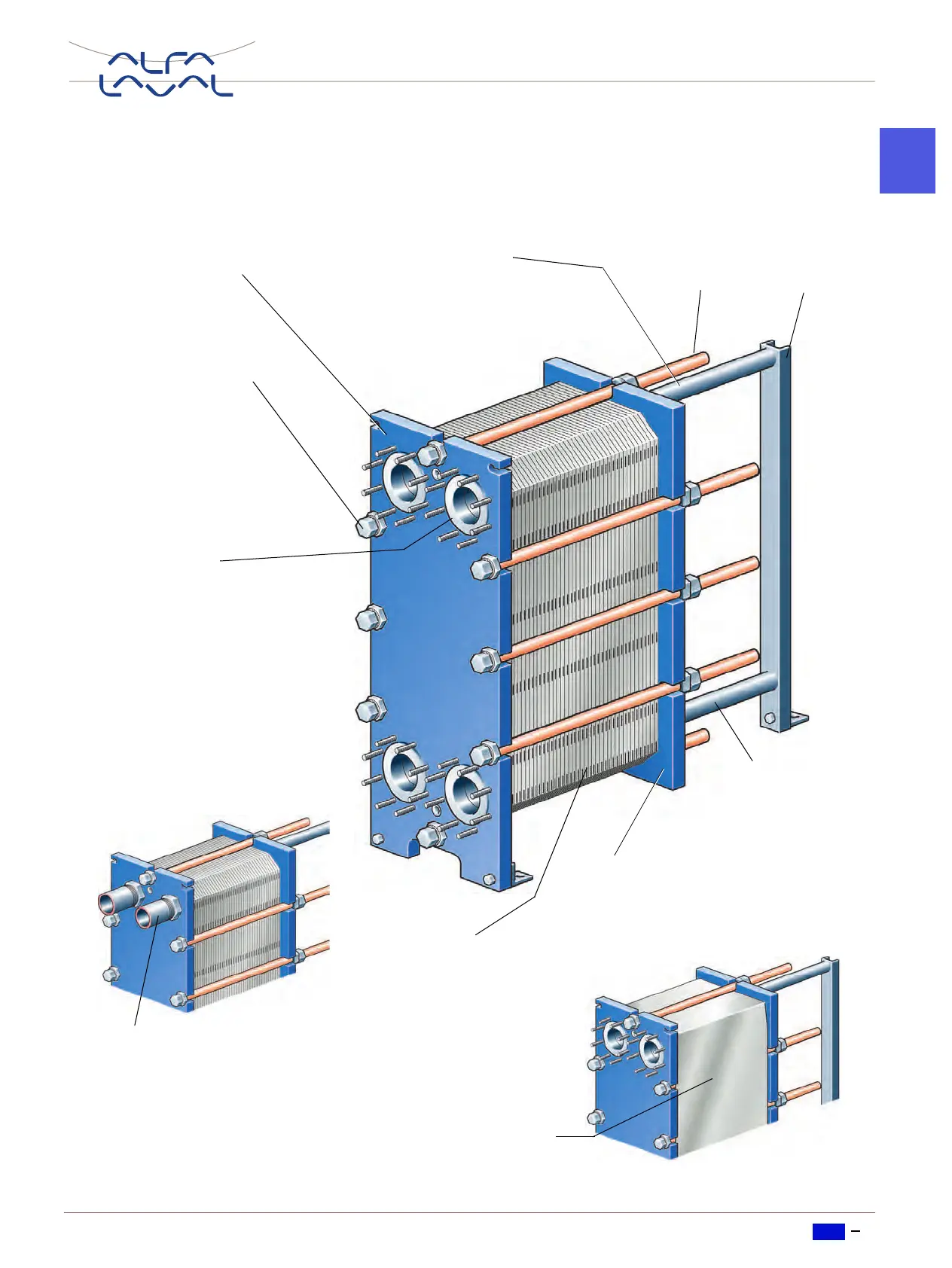

Protective sheets

In the USA mandatory, in

other countries optional.

Loading...

Loading...