9 of 36 © 2009 D 664 - 07/09

NO BOILER SENSOR (Boil SENS = NONE)

The 664 is capable of operating without a boiler sensor if desired. Without a boiler sensor,

the 664 is unable to provide boiler protection. In this mode of operation, the Stage 1 contact

is used to provide a boiler enable. When the mixing device begins to ramp up, the Stage 1

contact on the 664 closes. The Stage 1 contact remains closed until the mixing device no

longer requires heat. This type of application is typical if the 664 is drawing heat from a

source that already incorporates some form of boiler protection.

ROTATION (ROTATE)

The ROTATE item is an adjustable setting that is factory set at 48 hours. The firing order of the boiler changes whenever one stage’s

accumulated running time exceeds the other stage’s accumulated running time by more than the ROTATE setting. After each rotation,

the stage with the least running hours is the fi rst to fi re and the stage with the most running hours is the last to fi re. This function

ensures that both stages receive equal amounts of use. When this item is set to the OFF setting, Stage 1 is always the fi rst to fi re.

BOILER SENSOR ON THE RETURN (Boil SENS = RET)

The boiler sensor should be located on the boiler return if the 664 is one of many controls

that can call for boiler operation. When in the Return mode, the 664 provides a boiler

enable through the Stage 1 contact. The 664 no longer tries to control the boiler supply

water temperature directly, but allows the boiler to operate at its operating aquastat setting

when required. If this mode of operation is selected, the boiler pump should either operate

continuously, or be operated in parallel with the System Pump contact (Sys P1). When

the mixing device begins to ramp up, the Stage 1 contact closes on the 664. The Stage 1

contact remains closed until the mixing device no longer requires heat. With the sensor

on the boiler return, the 664 is still capable of providing boiler protection as described in

Section A.

Section D1

Snow Melting

Enable

Section D2

Snow Melting

Disable

The snow melting system can be enabled manually or automatically. A melting enable signal applied to the control places both zones

into the Melting mode. If a melting enable signal is applied once the system is already in the Melting mode, the control responds to

the last command received.

MANUAL MELTING ENABLE

A manual melting enable signal requires the user to manually start the snow melting system and can be provided from the Start button

on the control, Remote Start / Stop Module 039, Remote Display Module 040, or an external melt demand.

Section C2: Boiler Return Sensor

Section C3: No Boiler Sensor

Section D: Melting Enable / Disable

Section D1: Snow Melting Enable

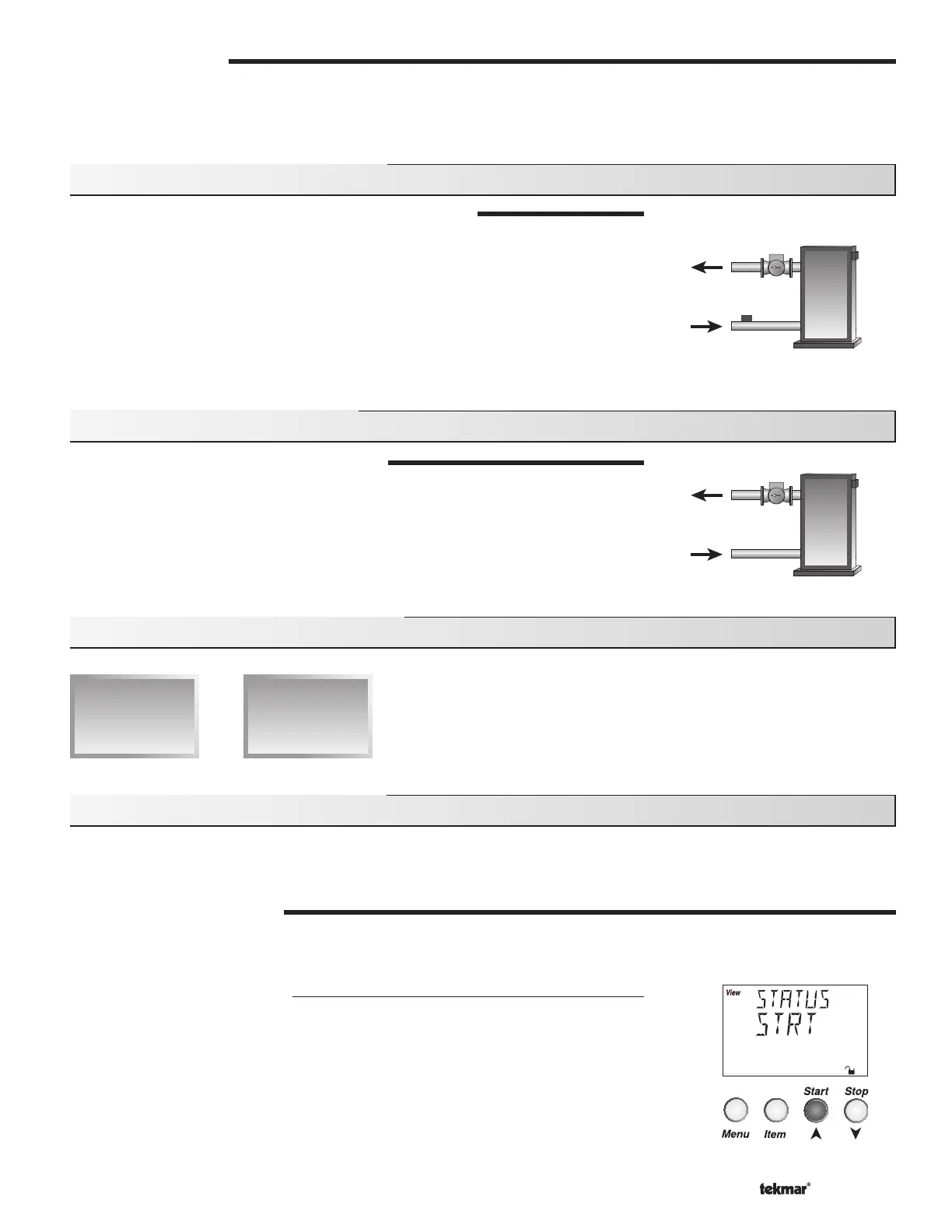

Start Button on the Control

The snow melting system is enabled by pressing the Start button on the control while

in the VIEW menu. The control then displays the RUN TIME setting to allow the user to

adjust it. Once the snow melting system is enabled, the word STRT is displayed for at

least 5 seconds in the STATUS item of the appropriate zone while in the VIEW menu. If

the Start button on the control is pressed while the zone(s) is already melting and up to

temperature, the running time counter is reset to the RUN TIME setting.

Loading...

Loading...