English Operation

6 Plate Heat Exchanger

EN

EN

Unit in operation

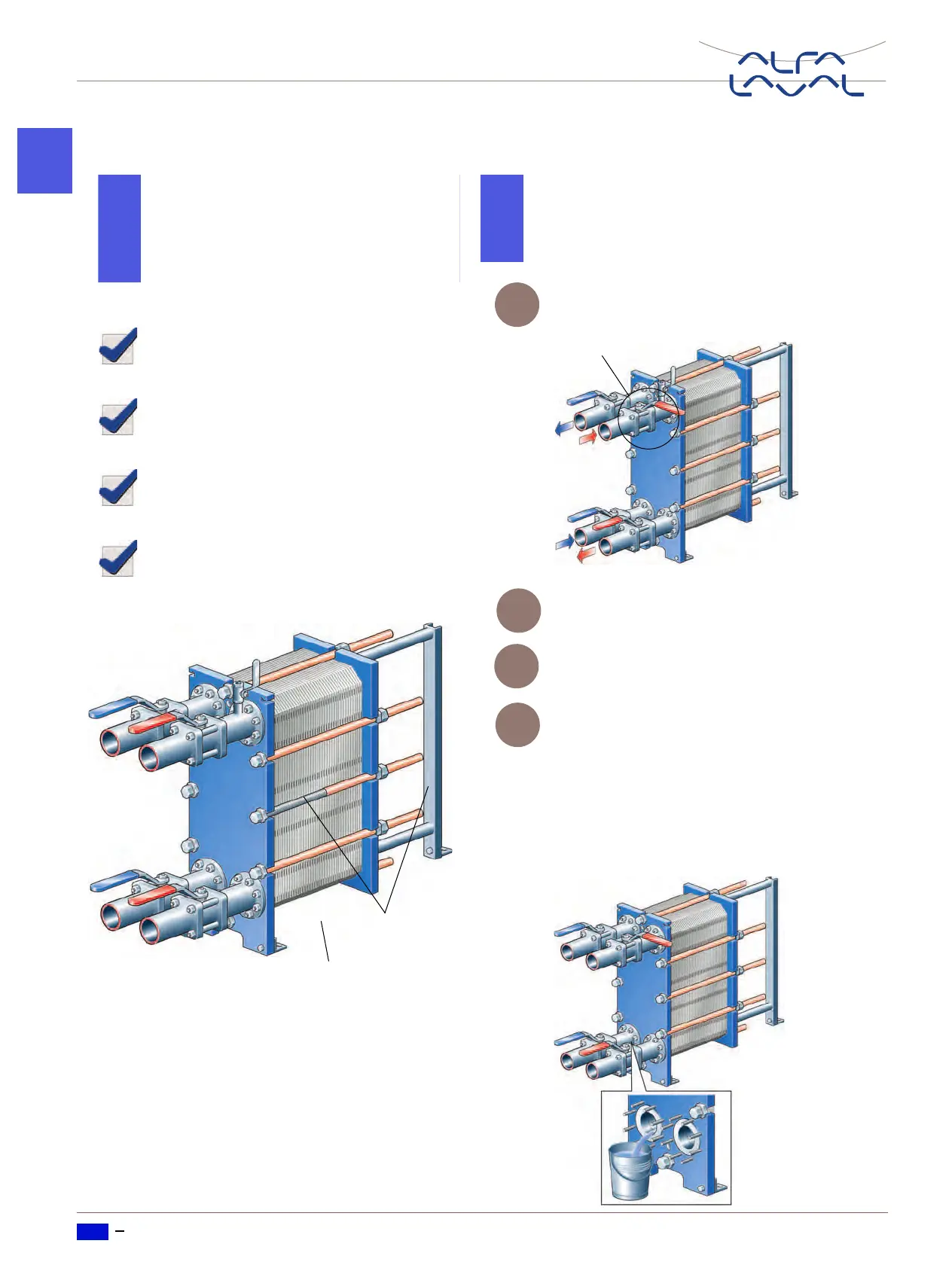

During operation, check that

media temperatures and pressures are

within the limits stated on the PHE-draw-

ing

no leakages appear due to faulty tighten-

ing of the plate pack or to defective or

damaged gaskets

support column, carrying bar and guiding

bar are kept clean and greased

the bolts are kept clean and greased.

Always consult your local Alfa Laval Representa-

tive for advice on

• new plate pack dimensions if you intend to

change number of plates

• selection of gasket material if operating temper-

atures and pressures are permanently

changed, or if another medium is to be proc-

essed in the PHE.

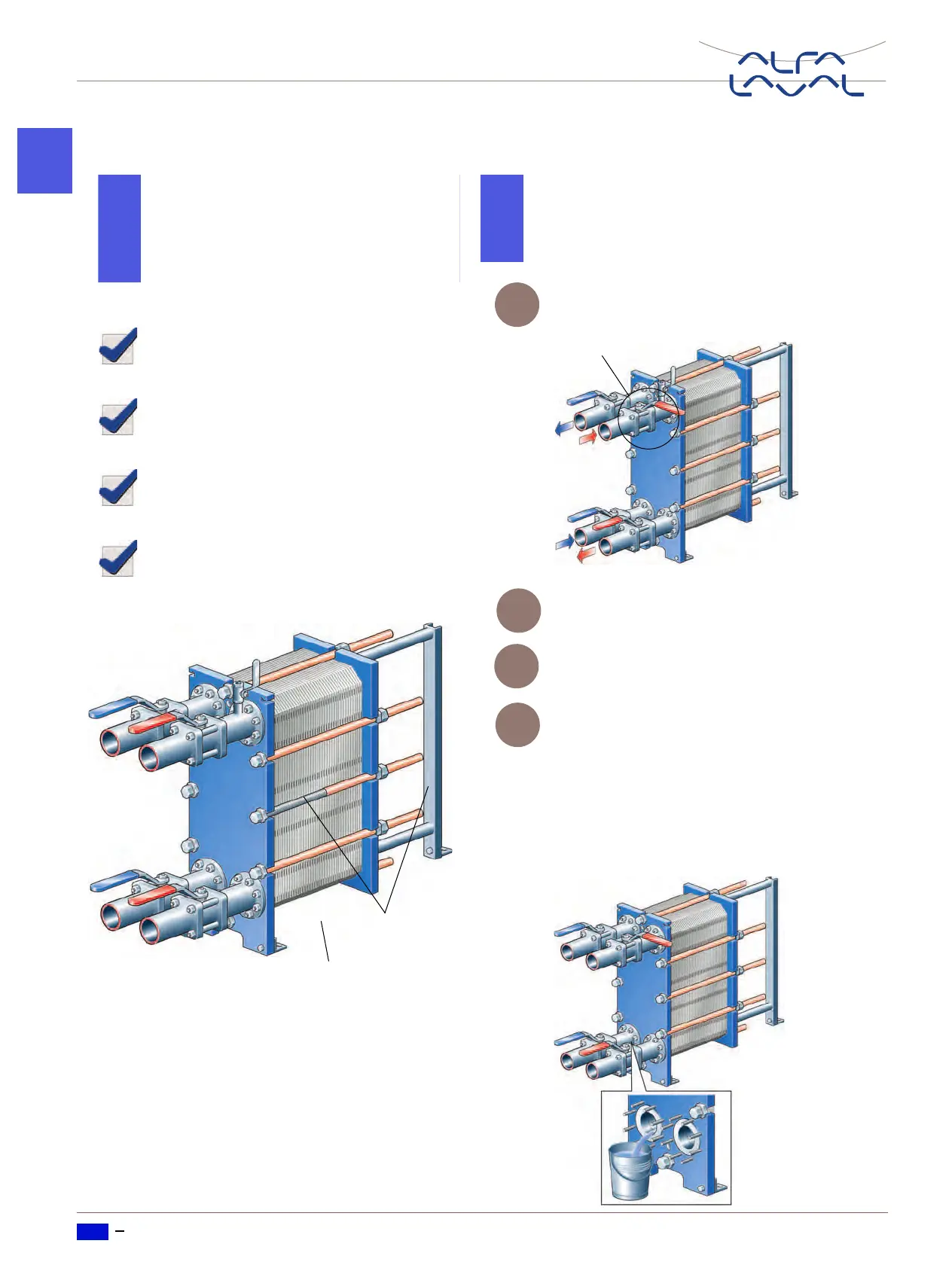

Shut-down

Slowly close the valve controlling the flow-

rate of the pump you are about to stop.

When the valve is closed, stop the pump.

Repeat steps 1–2 for the other side.

If the heat exchanger is shut down for sev-

eral days or longer, it should be drained.

Draining should also be done if the proc-

ess is shut down and the ambient temper-

ature is below freezing temperature of the

media. Depending on the media proc-

essed, it is also recommended to rinse and

dry the heat exchanger plates and connec-

tions.

Note!

Adjustments of flowrates should be made

slowly in order to protect the system

against sudden and extreme variations of

temperature and pressure.

No leakage

Clean and

greased

Note!

If several pumps are included in the system,

make sure you know which one should be

stopped first.

1

Close

2

3

4

Loading...

Loading...