English Maintenance

12 Plate Heat Exchanger

EN

EN

Closing

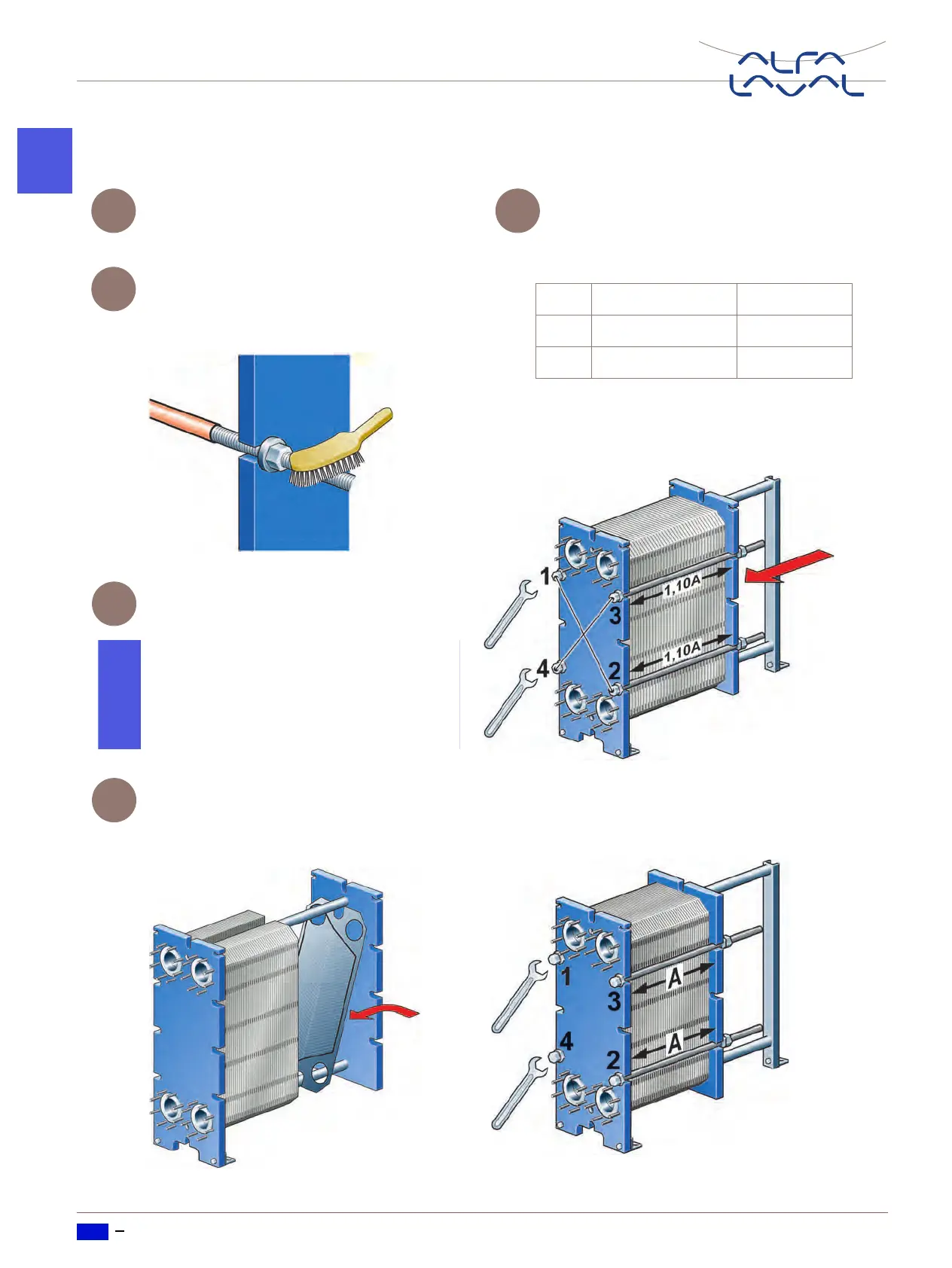

Check that all the sealing surfaces are

clean.

Brush the threads of the bolts clean, using

a steel wire brush. Lubricate the threads

with a thin layer of grease, e.g. Gleitmo

800 or equivalent.

Attach gaskets to the plates or check that

all the gaskets are properly attached.

Insert the plates with the herring bone pat-

tern positioned in alternate directions and

with the gaskets turned towards the frame

plate.

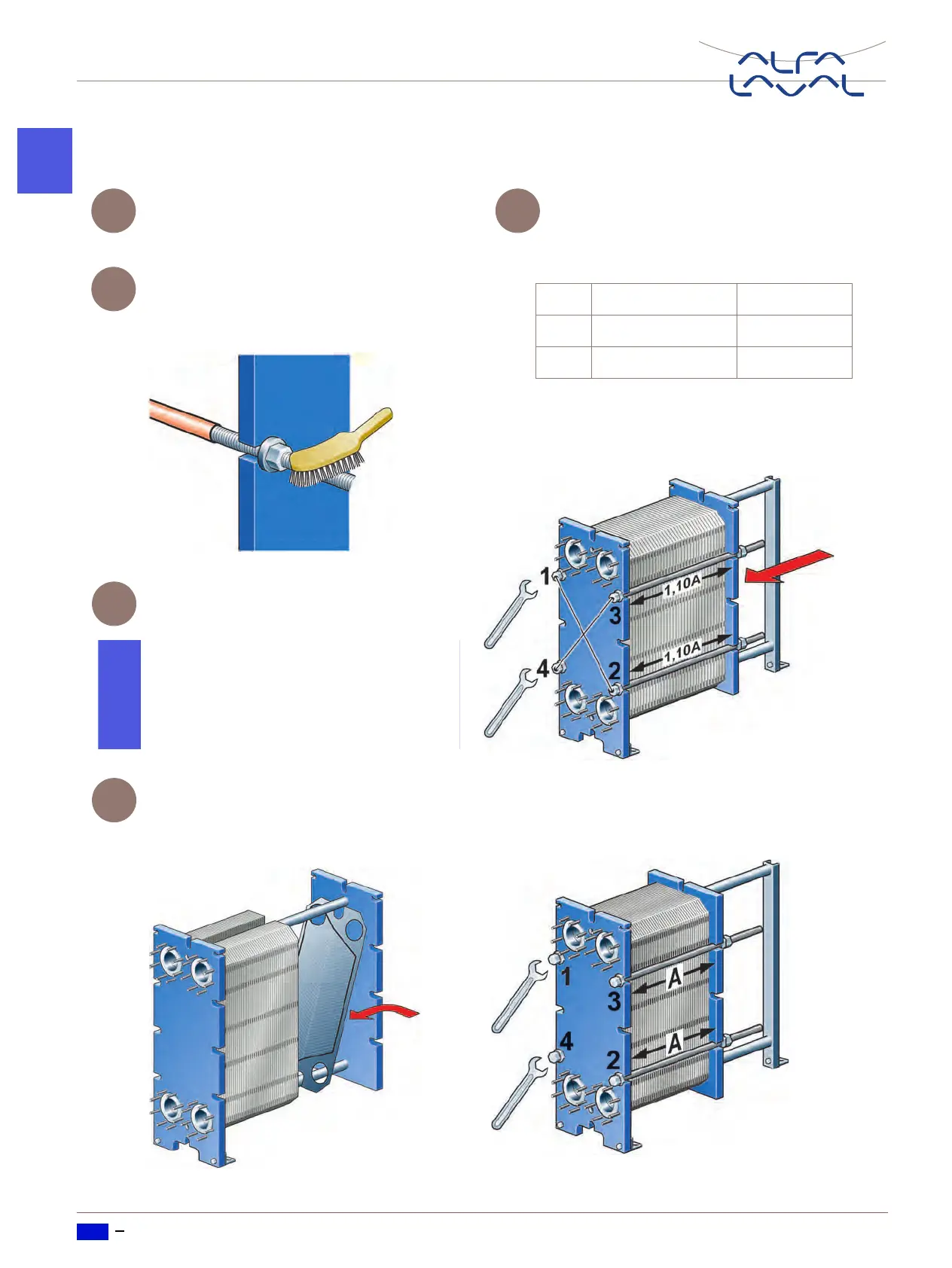

Press the plate assembly together. Tight-

ening is done in two steps, see figures be-

low. Be careful so that the frame plate and

the pressure plate are always in parallel.

Tighten the two diagonal pair of bolts alter-

nately until the plate package measures

1,10A.

After that bolts are tightened alternately

and diagonally, as shown in the figure be-

low.

1

2

3

Note!

If the gasket is wrongly positioned, it will

show by the fact that it rises out of the gas

ket groove or that it is positioned outside

the groove.

4

Step Bolt No. To dimension

1 1–2 or 3–4 1,10A

2 1–2–3–4 A

5

Loading...

Loading...