16 of 36© 2009 D 664 - 07/09

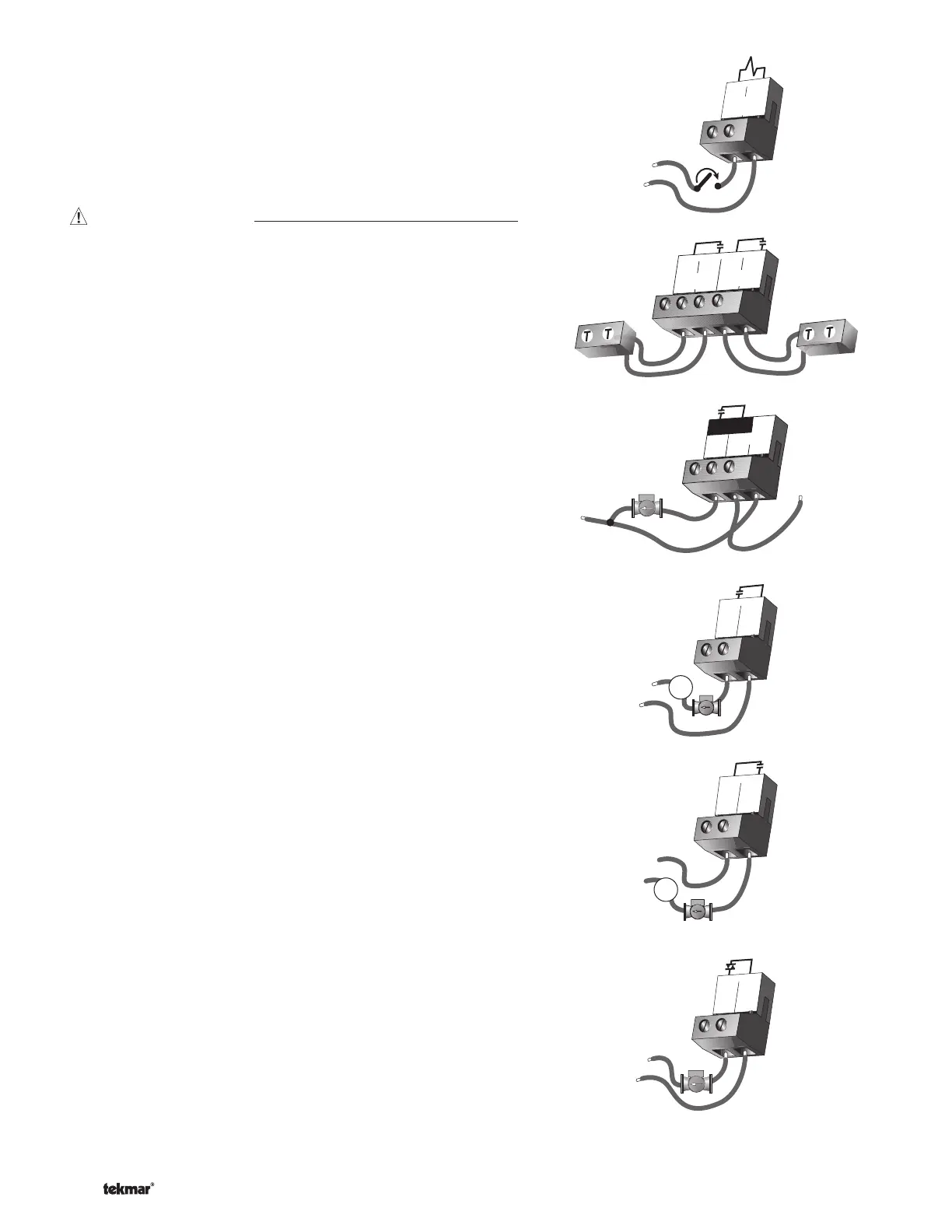

Melt / Idle Demand

To generate a melt demand or idle demand, a voltage between

24 V (ac) and 230 V (ac) must be applied across the Melt / Idle

Demand terminals (19 and 20).

Output Connections

Boiler Contacts

The Stage 1 and Stage 2 terminals (21, 22 and 23, 24) are isolated

outputs in the 664. There is no power available on these terminals

from the control. These terminals are used as a switch to either make

or break the boiler circuit. When the 664 requires the boiler(s) to fi re, it

closes the contact between terminals 21 and 22 and / or 23 and 24.

System Pump Contact (Sys P1)

The Sys P1 output terminal (28) on the 664 is a powered output.

When the relay in the 664 closes, 115 V (ac) is provided to the Sys P1

terminal (28) from the Power L terminal (29). To operate the system

pump, connect one side of the system pump circuit to terminal 28

and the second side of the pump circuit to the neutral (N) side of the

115 V (ac) power supply.

Zone Pumps and Zone Valves

The zoning outputs are isolated terminals in the 664. There is no

power available on these terminals from the control.

If zone 1 is used, connect the zone pump or zone valve circuit to the

Com Zn and Zn 1 terminals (26 and 25).

If zone 2 is used, connect the zone pump or zone valve circuit to the

Com Zn and Zn 2 terminals (26 and 27).

Variable Speed Injection Pump

The 664 can vary the speed of a permanent capacitor, impedance

protected or equivalent pump motor that has a locked rotor current

of less than 2.4 A. Most small wet rotor circulators are suitable as

described in Essay E 021. The 664 has an internal overload fuse which

is rated at 2.5 A 250 V (ac). Contact your tekmar sales representative

for details on the repair procedures if the fuse is blown.

If a variable speed injection pump is used, connect one of the wires

from the variable speed injection pump to the Opn / Var terminal (3)

on the 664. Connect the Pwr Mix terminal (4) to the live (L) side of

the 115 V (ac) power source. The other wire on the variable speed

injection pump must be connected to the neutral (N) side of the

115 V (ac) power supply.

19

20

Melt / Idle

Demand

24 to 230 V (ac)

L

N

22

21

23

24

Stage

1

Stage

2

Sys

P1

115 V (ac)

N

L

Power

30

L

N

29

28

25

Zn

1

26

Com

Zn

M

24 to 230 V (ac)

L

N

OR

26

Com

Zn

27

Zn

2

M

24 to 230 V (ac)

L

N

OR

3

4

Pwr

Mix

Opn/

Var

115 V (ac)

N

L

Loading...

Loading...