10

APCD-500, rev10

APCD-500

4.3. Feed Distribution Modes

4.3.1. Timed Feed Distribution

When feed is distributed according to a timer,

the user chooses at what time the Chain Disk

Systems start being filled and at what time

feed starts being delivered to the animals. Up

to daily 25 feed cycles can be programmed.

Refer to section 5.6 to enable the timed feed

distribution method.

Location of the optional proximity

sensor in timer mode

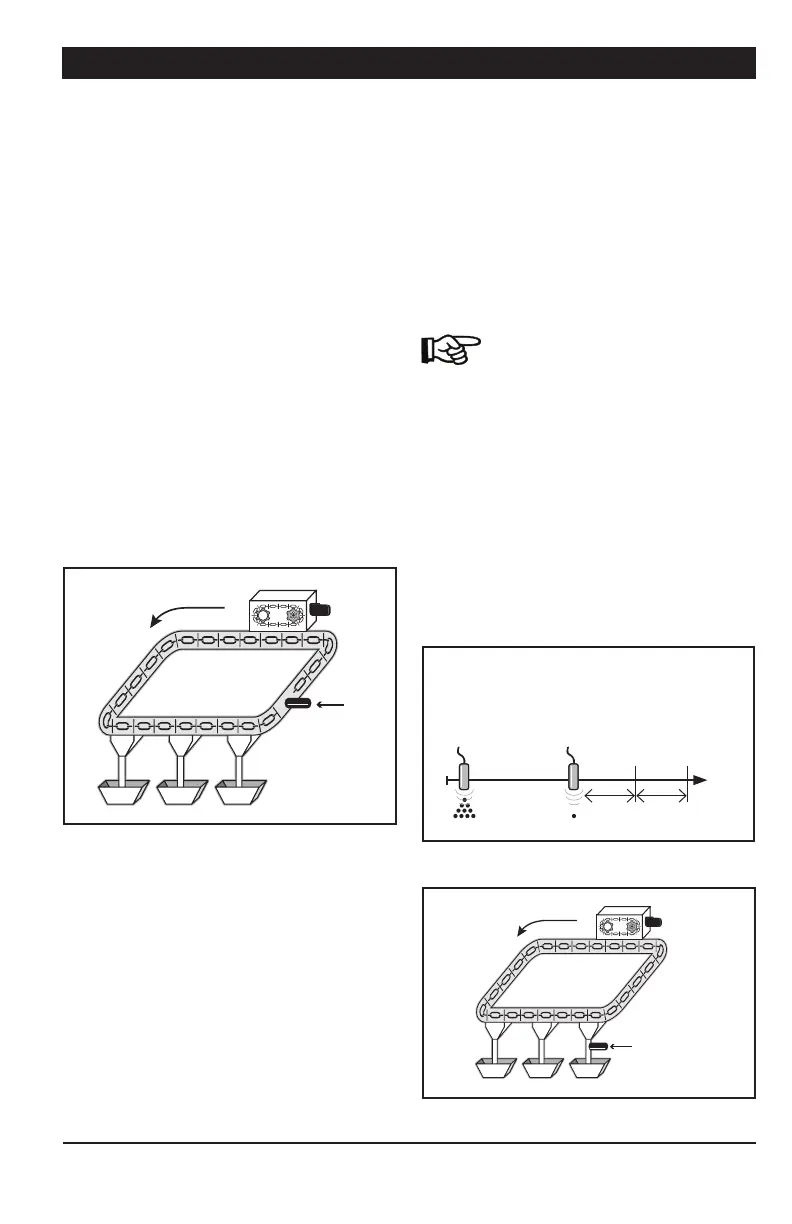

When feed is distributed according to a timer,

a proximity sensor can be used to stop the

Chain Disk Systems when feed is detected

(see illustration). One proximity sensor must

be located at the end of each Chain Disk

System.

Proxy on

the Chain

Disk System

line after

the last

drop and

before the

fill hopper

Last drop

Drive unit

4.3.2. Continuous Feed Distribution

The continuous feed distribution mode

ensures the system is always full: the bin

auger starts bringing feed into the Chain

Disk System as soon as it gets empty. In

this operating mode, the proximity sensor

can either be mounted in the last drop or on

the Chain Disk System line after the last drop

and before the fill hopper.

Refer to section 5.6 to specify the

location of the proximity sensor.

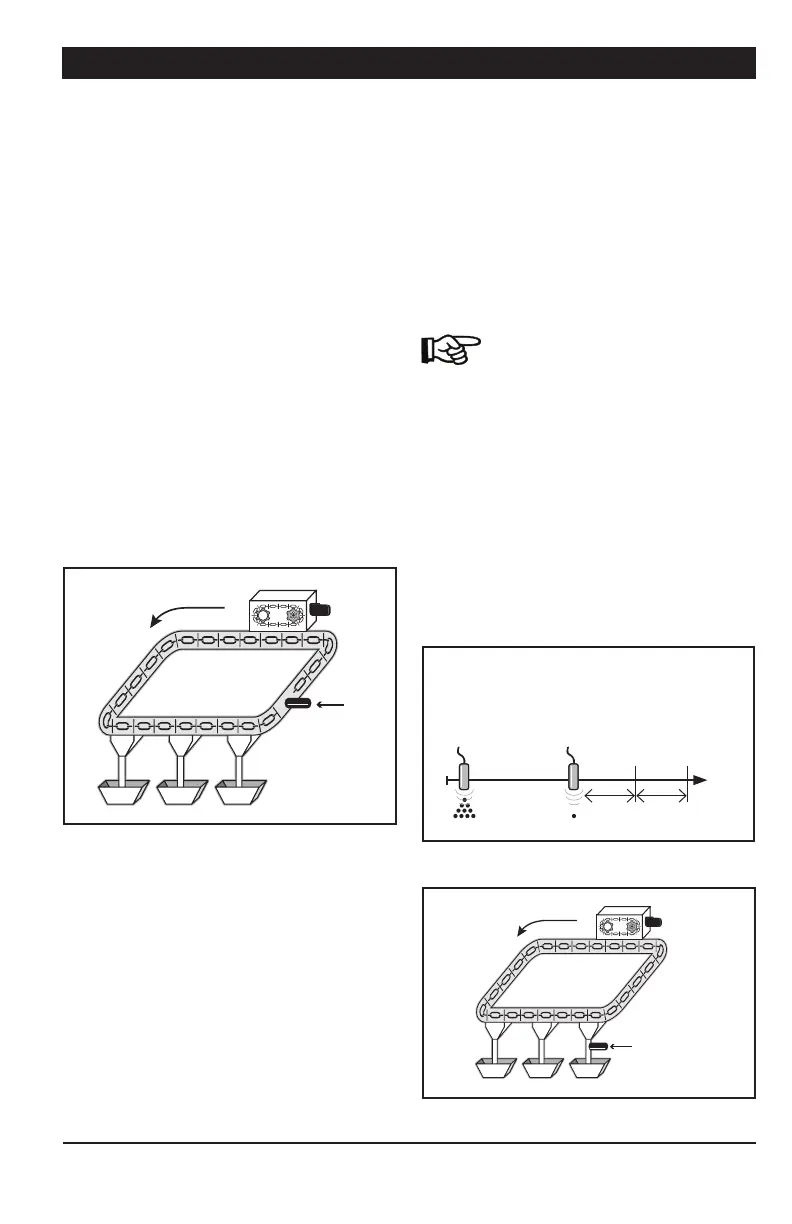

Continuous Mode —

Proximity sensor in the last drop

If a proximity sensor is located in the last

drop of the Master Chain Disk System, the

system is considered as being full when the

proximity sensor detects feed. Once the

system is full, the controller waits for drop

tube to empty out before launching a new

feed cycle (the drop tubes are considered as

being empty when the proximity sensor stops

detecting feed).

Feed is detected

by the master

proximity sensor

(the system is full)

Cont.

Feeding

Delay

Bypass

Delay

etc.

A new feeding cycle

starts when feed stops

being detected by the

master proximity sensor

(the drop tube is empty)

Proxy in Last Drop

Proximity

sensor in

drop

Last drop

Drive unit

Loading...

Loading...