8

APCD-500, rev10

APCD-500

4. CONTROLLER OVERVIEW

4.2. Chain Disk System

Setups

Up to 7 slave units (APCD-500-S) can be

used to drive additional Chain Disk Systems.

These supplementary Chain Disk Systems

can share common bin augers, they can be

linked together, or they can operate inde-

pendently one from another. The following

section explains the three possible Chain

Disk System setups that can be managed by

the controller. Refer to the Installation Setup

chapter to select your specific Chain Disk

System setup.

• Timed or continuous feed cycles;

• With or without proximity sensors.

• With or without actuators / air valves to

open the drops;

• With commun or individual bin augers;

• With one or multiple Chain Disk Systems;

• With cascade or independent Chain Disk

setups.

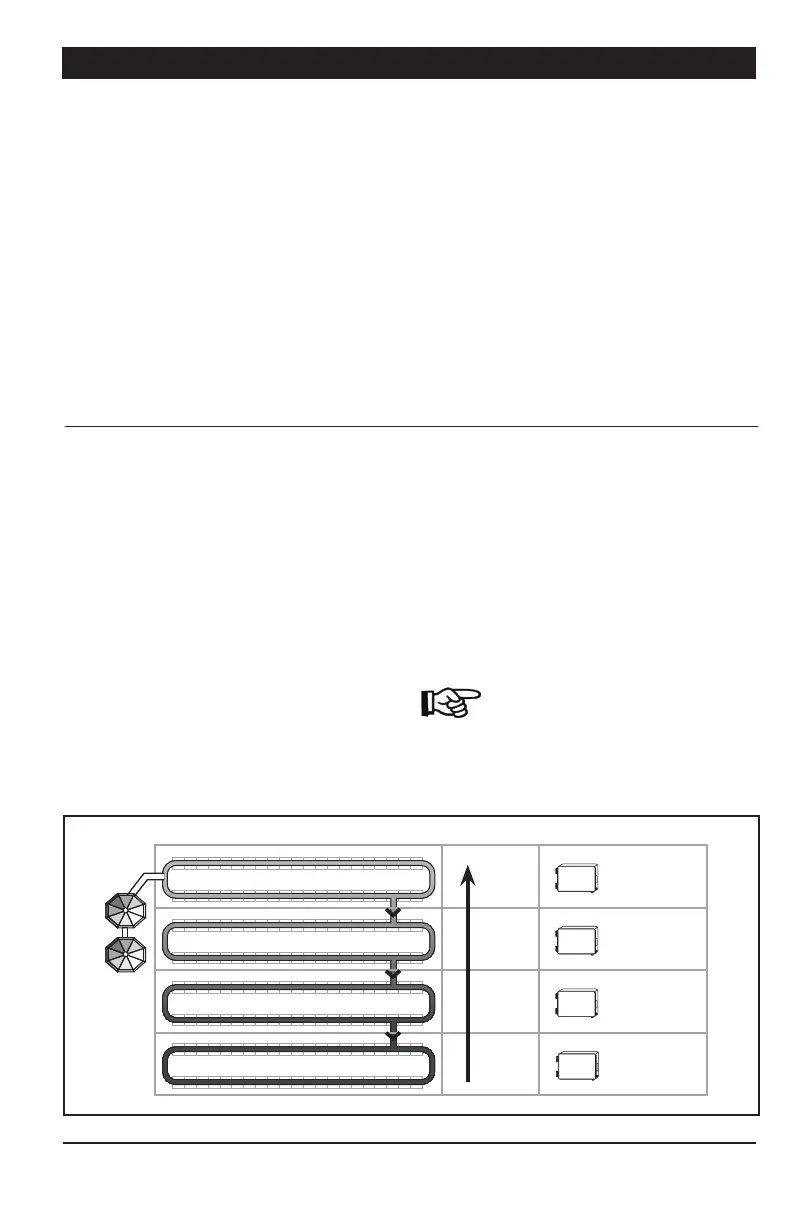

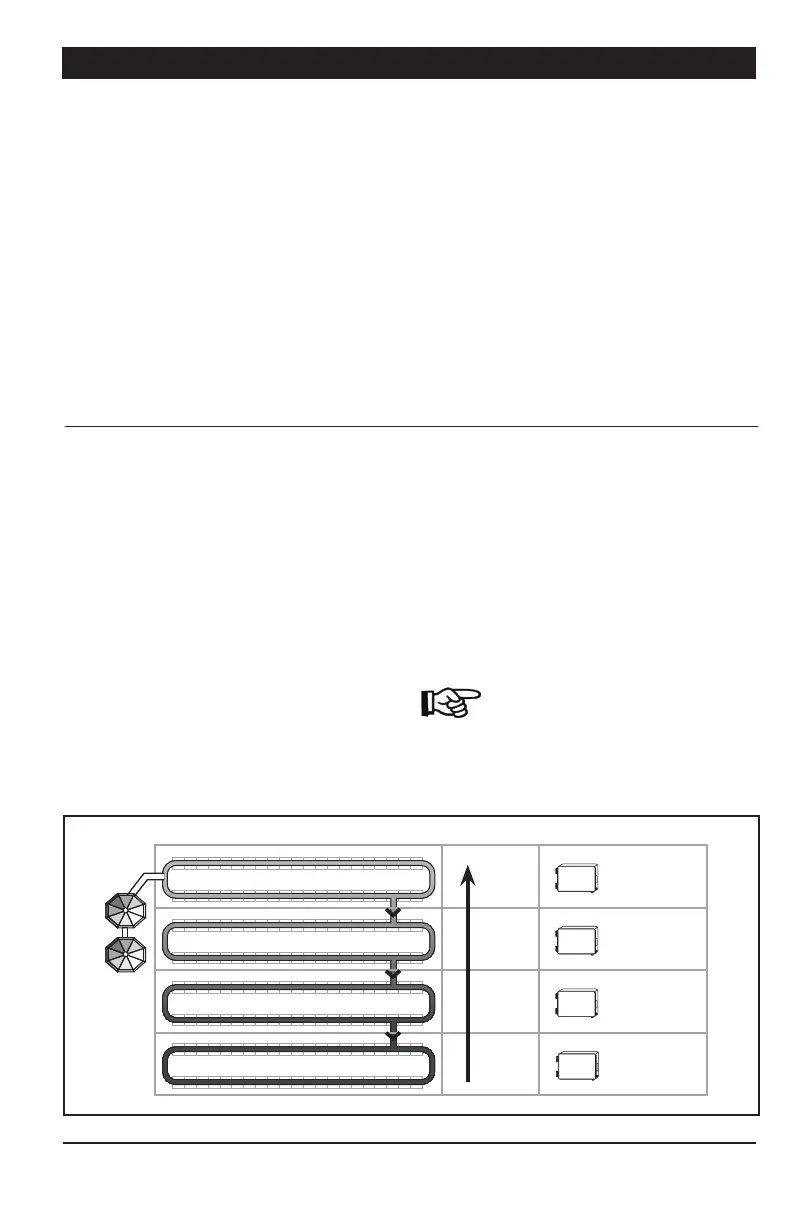

4.2.1. Cascade Setup

In this setup, all Chain Disk Systems are

connected together and share a common

bin auger. When this auger starts bringing

feed into the Chain Disk Systems, all drive

units start running to send feed towards the

farthest Chain Disk System (APCD-500-S

unit with the highest ID number). When the

farthest Chain Disk System is full, the feed

fills the preceding Chain Disk System, etc.

Refer to sections 4.4.1 & 4.4.2 to get

information about the filling process

in this Chain Disk System setup.

Cascade Setup

4.1. Features

The APCD-500 controls the feed entry into

Chain Disk Systems and the distribution of

feed to the animals. When used in combina-

tion with APCD-500-S auxiliary units, this

controller can control up to 8 Chain Disk

Systems.

Due to its great number of options, the

APCD-500 controller can suit most Chain

Disk setups:

APCD-500

MASTER

APCD-500-S

ID 1

APCD-500-S

ID 2

APCD-500-S

ID 3

Bins

Chain Disk Systems Filling Order Controller & ID#

Last

Third

Second

First

Loading...

Loading...