18

APCD-500, rev10

APCD-500

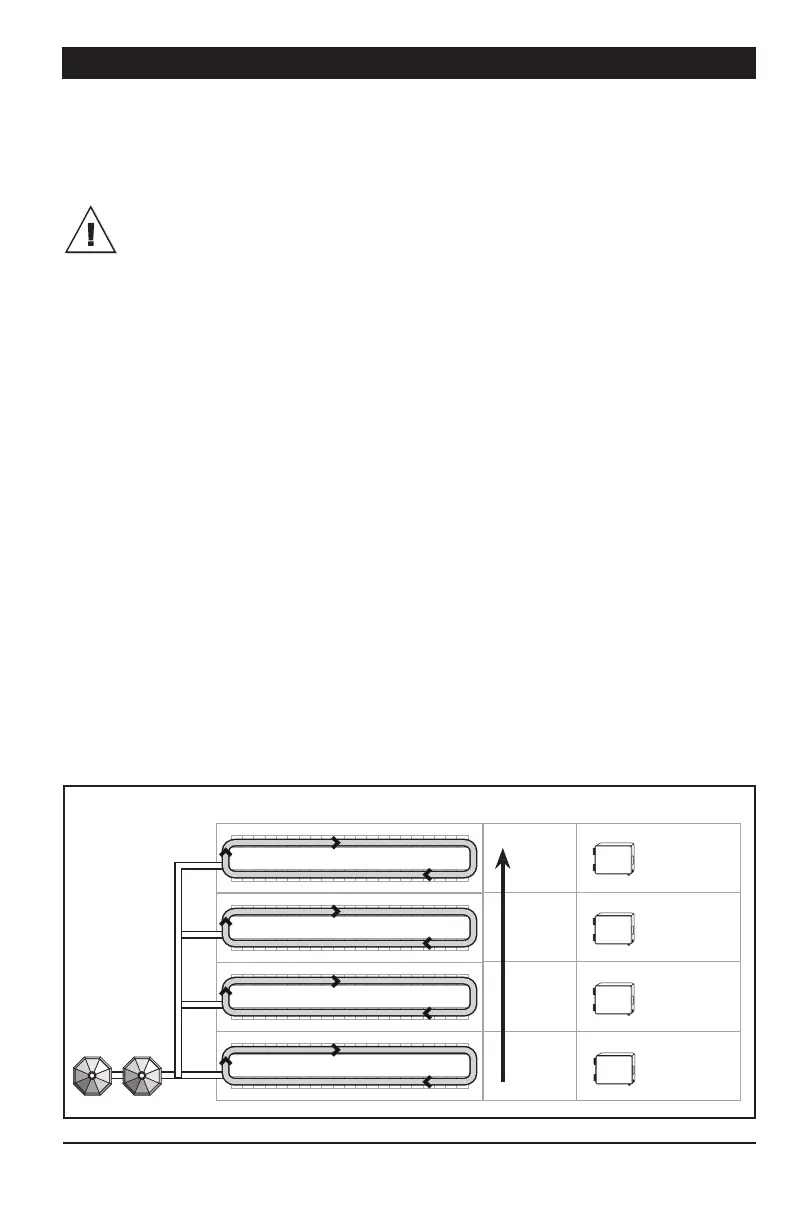

4.4.3. Filling Independent Chain Disk

Systems with a Common Bin Auger us-

ing Continuous Feed Distribution Mode

The common bin auger must be con-

nected to the master APCD module!

1. Beginning the Filling Process — The fill-

ing process starts at the end of the previous

cycle (refer to point 7 below to see when a

cycle ends).

2. Emptying the Bin Auger and Chain Disk

Systems — When the “Continuous Delay” has

elapsed, the controller activates all drive

units during the “Purge Time” and launches

the “A u g e r D e l a y” . When the “A u g e r D e l a y” has

elapsed, the bin auger starts sending feed to-

wards the Chain Disk Systems. Normally, the

“Purge Time” must be longer than the “A u g e r

Delay” to prevent feed from accumulating at

the end of the bin auger.

3. Filling the First Chain Disk System —

When the “Purge Time” is over, all drive units

stop except for the first Chain Disk System

to be filled: the master Chain Disk System.

4. The Chain Disk System is Full — The

controller knows the Chain Disk System is

full when the proximity sensor located at its

end detects feed for 5 seconds without inter-

ruption. When feed is detected, the drive unit

of this Chain Disk System stops.

5. Filling the Chain Disk Systems One by One

— Each time a Chain Disk System gets full, its

drive unit stops running and the next Chain

Disk System starts being filled (Chain Disk

Systems are being filled in numerical order).

6. The Last Chain Disk System is Full — When

the last Chain Disk System is full (i.e., the

slave Chain Disk with the highest ID #), all

drive units are off and the bin auger stops

bringing feed into the system.

7. Next cycle — The next feed cycle starts

when the last Chain Disk System gets empty:

a) If the proximity sensor is mounted in the

last drop, the next cycle starts when the

proximity sensor stops detecting feed.

b) If the proximity sensor is on the Mas-

ter Chain Disk System line after the last

drop, the new cycle starts if no feed is

detected after 2 delays: “Continuous Feed

Delay” + “Bypass Delay” (the “Continuous

Feed Delay is the amount of time required

for the animals to eat the feed).

Back to step 1.

Last

Third

Second

First

APCD-500-S

ID 3

APCD-500-S

ID 2

APCD-500-S

ID 1

APCD-500

MASTER

Chain Disk Systems Filling Order Controller & ID#

Bins

Loading...

Loading...