11

APCD-500, rev10

APCD-500

4.4. Filling Process

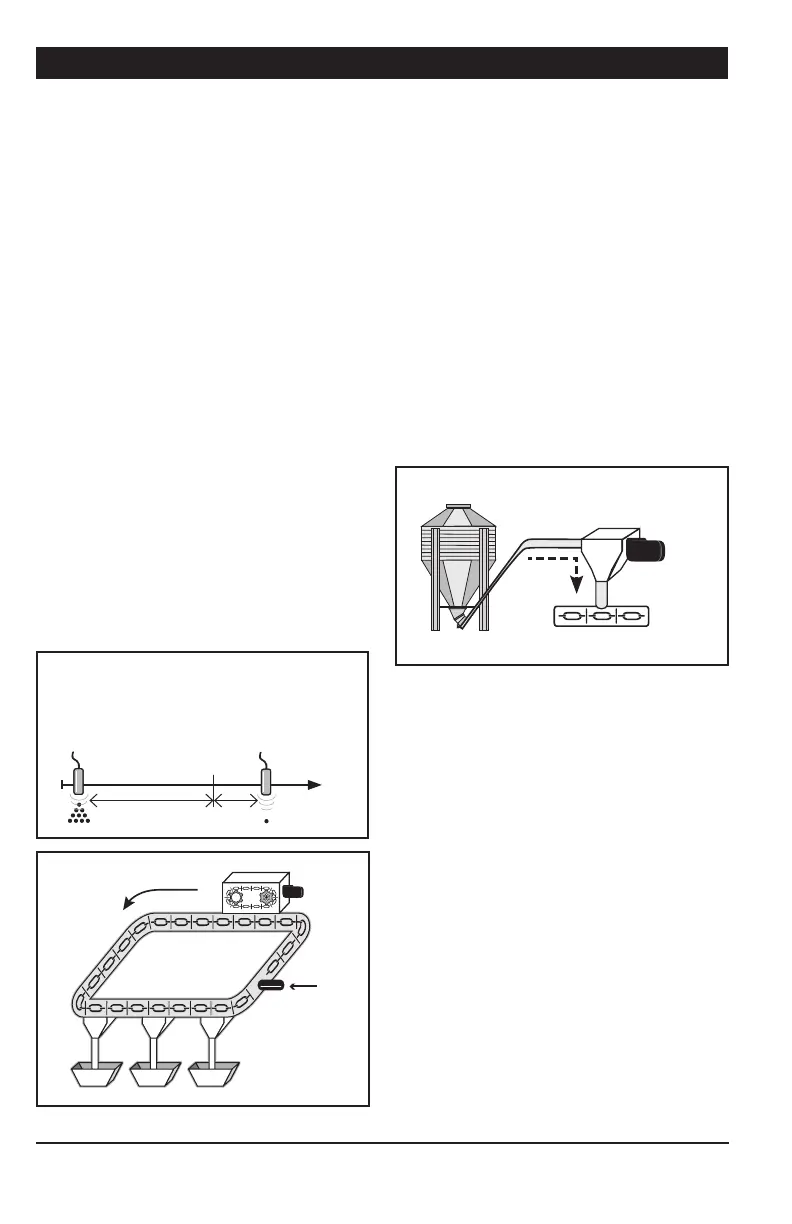

Operation of the Bin Auger:

At the start-up of each feeding cycle, right

after the Auger’s Delay has elapsed, the bin

auger starts bringing feed into the Chain Disk

Systems and stops when the Chain Disk Sys-

tem is full. There are two ways the controller

can detect that a Chain Disk System is full:

1. The proximity sensor detects feed for

5 seconds without interruption;

2. The drive unit has been running for the

“Max Run Time” parameter value (only if no

proximity sensor is used).

Feed Line

Auger

Auger

Motor

Bin

Chain Disk Overload Protection:

The controller monitors the amperage draw of

Chain Disk drive units to prevent overloading

the system:

•Iftheamperageexceedsthelimit“Max

Current Consumption” limit, the controller

temporarily shuts down the bin auger

while the Chain Disk keeps running in

order to discharge the feed. As the feed

load decreases the amperage draw also

decreases; the bin auger restarts when

the current consumption gets lower than

the “Max Current Consumption - Window Size”.

•Iftheamperagedrawgetshigherthan

the “Critical Current Consumption” for more

than the “Critical Delay”, the system stops

and will not restart.

Continuous Mode —

Proximity sensor on the Chain Disk

System Line after the Last Drop

If the proximity sensor is located on the Chain

Disk System line after the last drop, the system

is considered as being full when the master

proximity sensor detects feed. At that mo-

ment, the controller launches the “Continuous

Feed Delay” (which represents the amount of

time required for the animals to eat the feed).

When the “Continuous Feed Delay” has elapsed,

all Chain Disk Systems start running again

during the “Feed Bypass Delay”.

a) If the master proximity sensor still detects

feed after the “Feed Bypass Delay”, the control-

ler relaunches the “Continuous Feed Delay” and

the “Feed Bypass Delay” again since the system

is not empty yet. This process is repeated

up until the master proximity sensor stops

detecting feed.

b) If no feed is detected in the master Chain

Disk System after the “Feed Bypass Delay”, the

controller restarts a new feed cycle in order

to refill the whole Chain Disk.

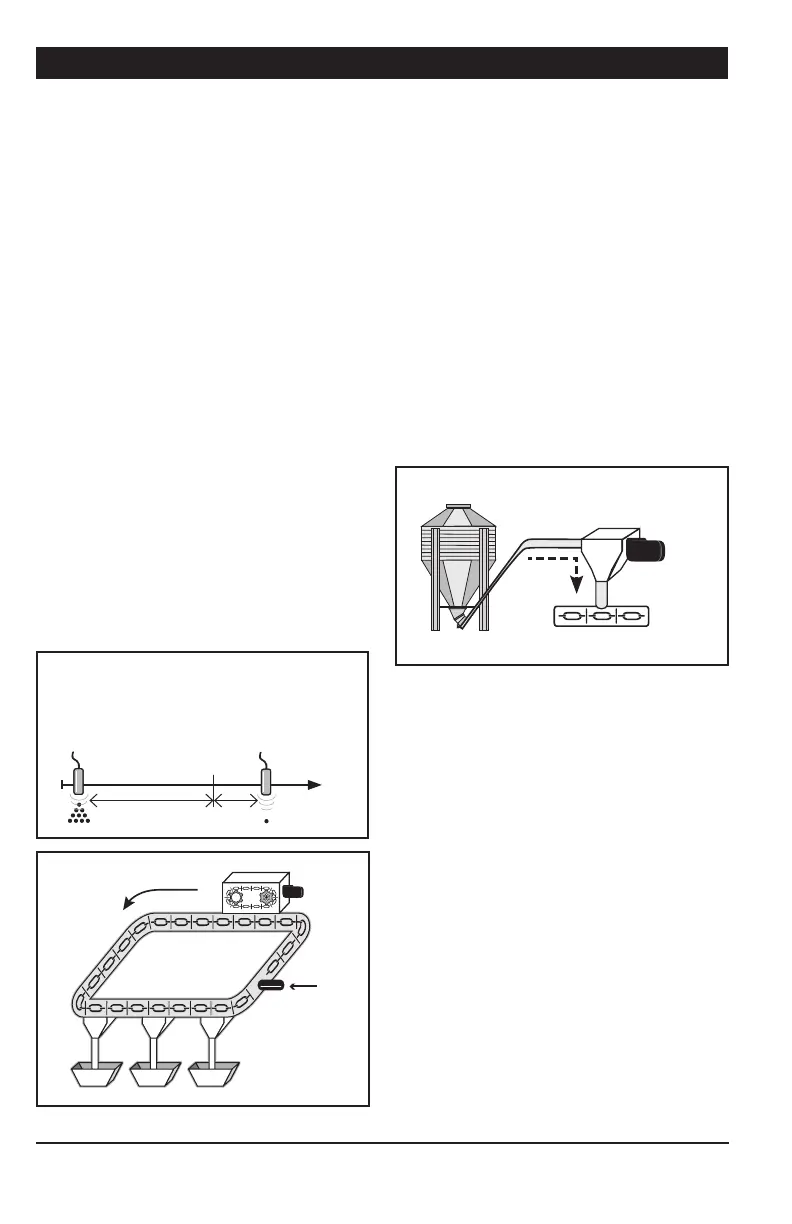

Feed is detected

by the master

proximity sensor

(the system is full)

Continuous Feeding

Delay

Bypass

Delay

The system is

empty when no feed

is detected after the

“Continuous Feed Delay”

+ “Feed Bypass Delay”.

A new feeding cycle

then starts.

Proxy in Feed Line:

Proximity

sensor on

the Chain

Disk System

line after

the last

drop

Last drop

Drive unit

Loading...

Loading...