25

APCD-500, rev10

APCD-500

4.4.6. Filling Independent Chain

Disk Systems with Individual Bin Au-

gers Using the Timed Feed Distribu-

tion Mode

1. Beginning the Filling Process — The filling

process starts at the start-up of a feed cycle

(defined by the “Cycle Time” parameter).

2. Cleaning the Drops — If actuators are

used and the “Clean Drop” option is enabled

in the INSTALLATION menu, the controller

opens and closes the drops 3 times in a row

to evacuate feed leftovers from the system.

3. Emptying Chain Disk Systems — To en-

sure all Chain Disk Systems are empty before

bringing new feed, the controller activates

all drive units during their respective “Au g e r

Delay”.

4. Filling Chain Disk Systems — When the

“A u ge r D e l a y” of a Chain Disk System has

elapsed, the Chain Disk System keeps running

and its respective bin auger starts sending

feed towards this Chain Disk System.

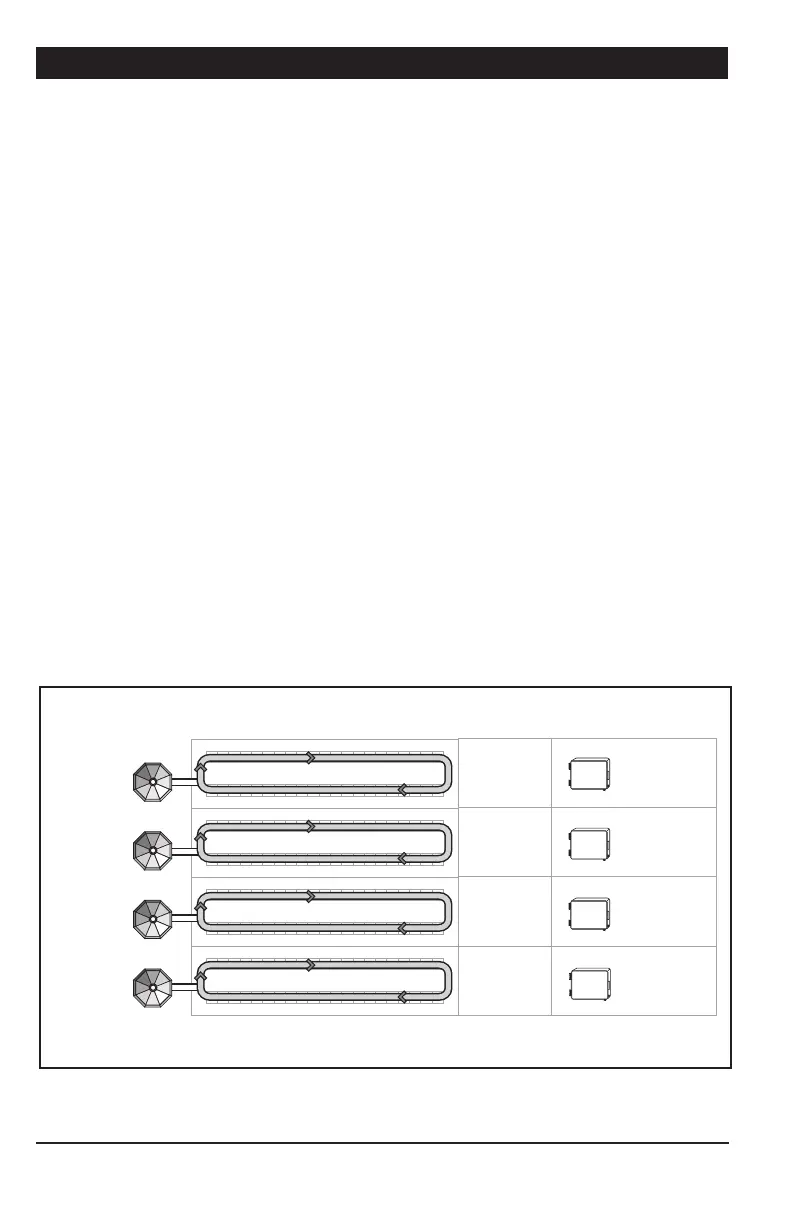

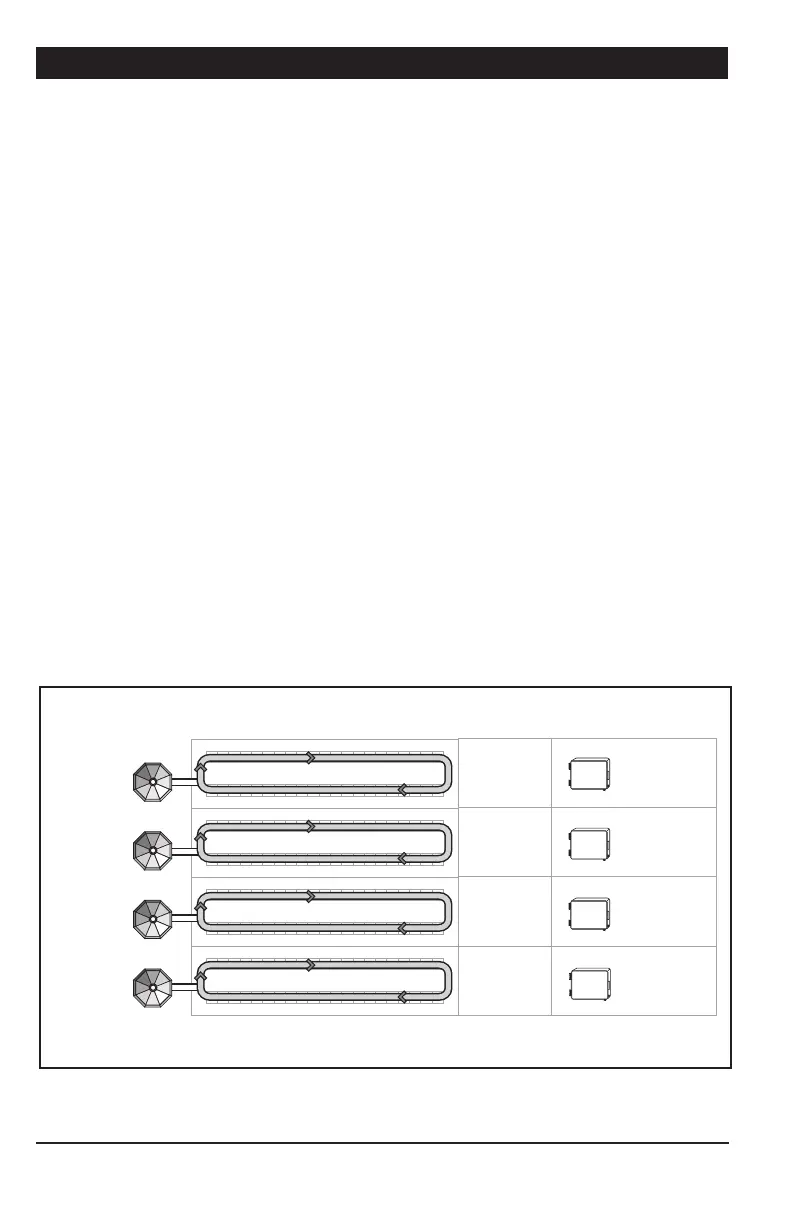

Simultaneous

Simultaneous

Simultaneous

Simultaneous

APCD-500-S

ID 3

APCD-500-S

ID 2

APCD-500-S

ID 1

APCD-500

MASTER

Chain Disk Systems Filling Order Controller & ID#

5. The Chain Disk System is Full:

• If a proximity sensor is used:

The controller knows a Chain Disk System

is full when the proximity sensor detects

feed for 5 seconds. When feed is detect-

ed, the controller stops the feed entry (bin

auger) and the drive unit keeps running

for the “Shutdown Delay” and then stops.

• If no proximity sensor is used:

The controller knows the Chain Disk

System is full when the drive unit has

been running for its respective “Run Time”

parameter value. The drive unit of this

Chain Disk System stops when its “Run

Time” has elapsed.

6. Feed Dumping — When the Chain Disk

system is full, feed is ready to be delivered

to the animals. Step to section 4.4.

Loading...

Loading...