10 Maintenance

Topics Covered in this Chapter

▪ Lubrication Guide

▪ Belt Tensioning

Lubrication Guide

The motor bearings use a No. 2 consistency lithium complex base grease.

The following lubrication table is a general guide for normal operating conditions. However, if the bearing

is subjected to excessive operating conditions, a more frequent schedule may be needed.

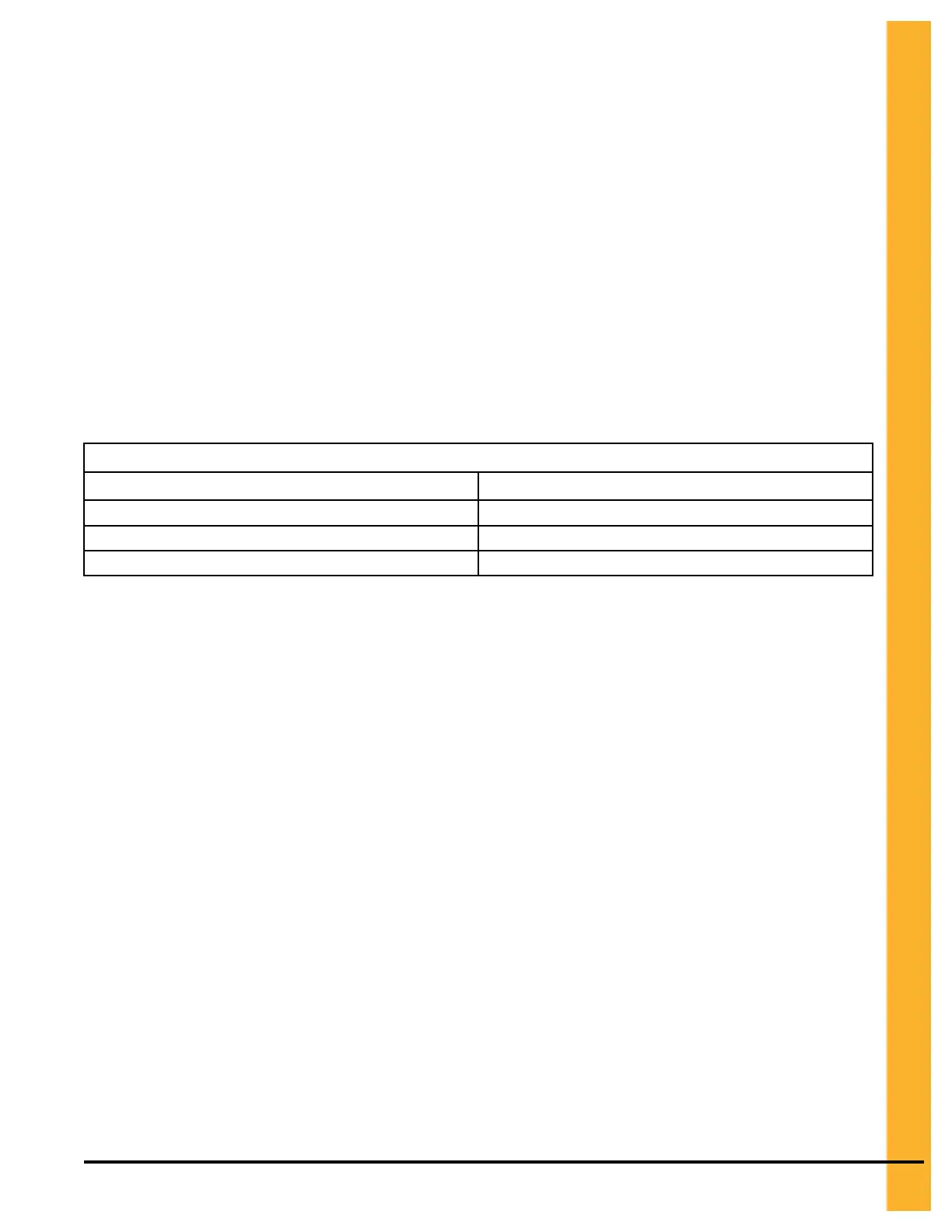

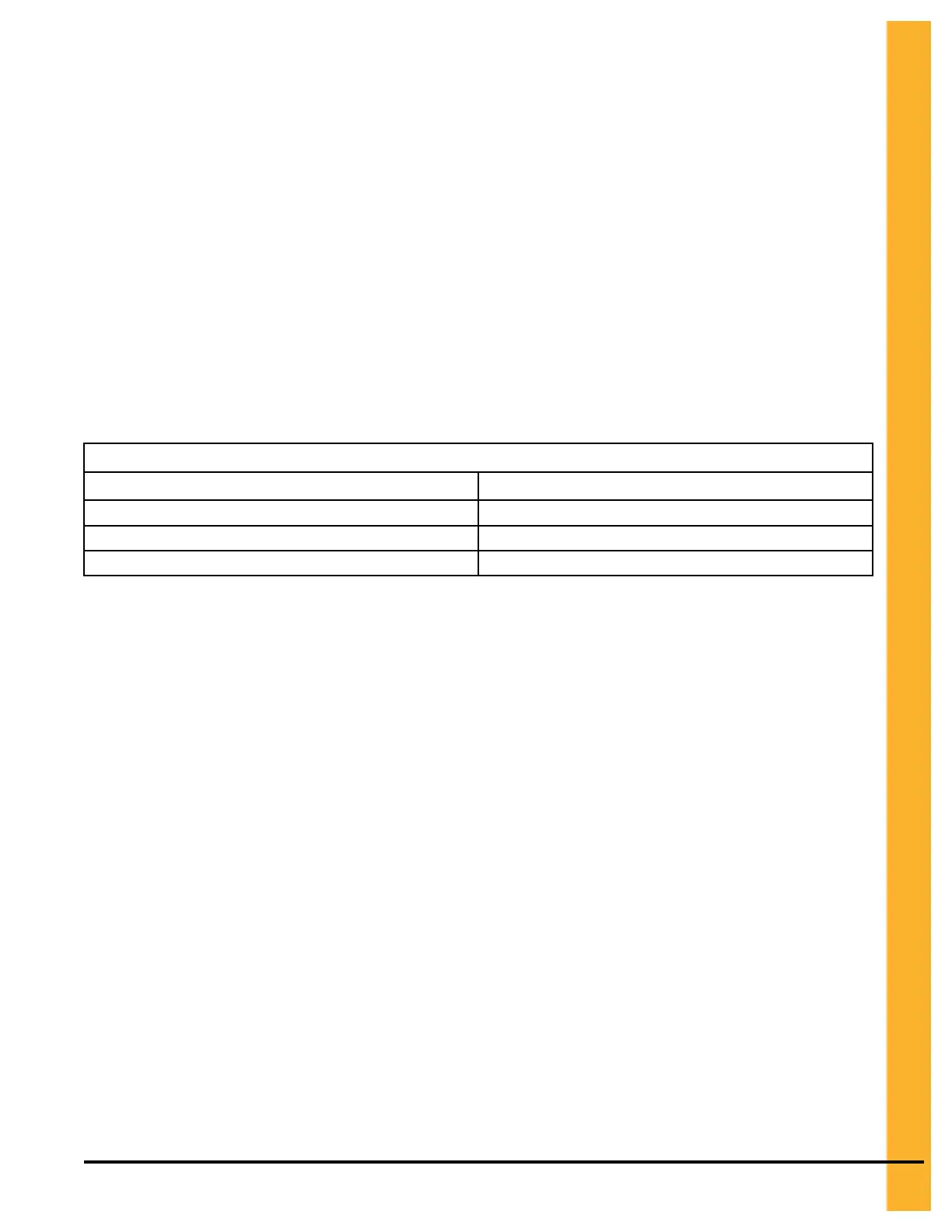

Suggested Lubrication Period in Weeks

Hours run per day 751 to 1500 rpm

8

7

16 4

24 2

Storage or special shutdown

If the dryer will be idle for some time, before shutting down, add grease to the bearing until the grease

purges from the seals. This will ensure protection of the bearing, particularly when exposed to the severe

environmental conditions. After storage or an idle period, add fresh grease to the bearing before

operating.

Belt Tensioning

If any of the following conditions exist, adjust the tension on the belts until they are alleviated:

• The belts squeal as the motor is turned on.

• The belts do not have a slight bow on the slack side when they are operating at full loads. A properly

tensioned belt will have a slight bow. The belts could be too loose or too tight.

• The sheave is excessively hot. To test, shut off power sources and lock out controls. Hold your

finger in the sheave groove, it should be warm but not too hot to touch. If it is to hot, the belt tension

should be loosened.

PNEG–2088 Quiet Portable Dryer

69

Loading...

Loading...