Rev.7 27

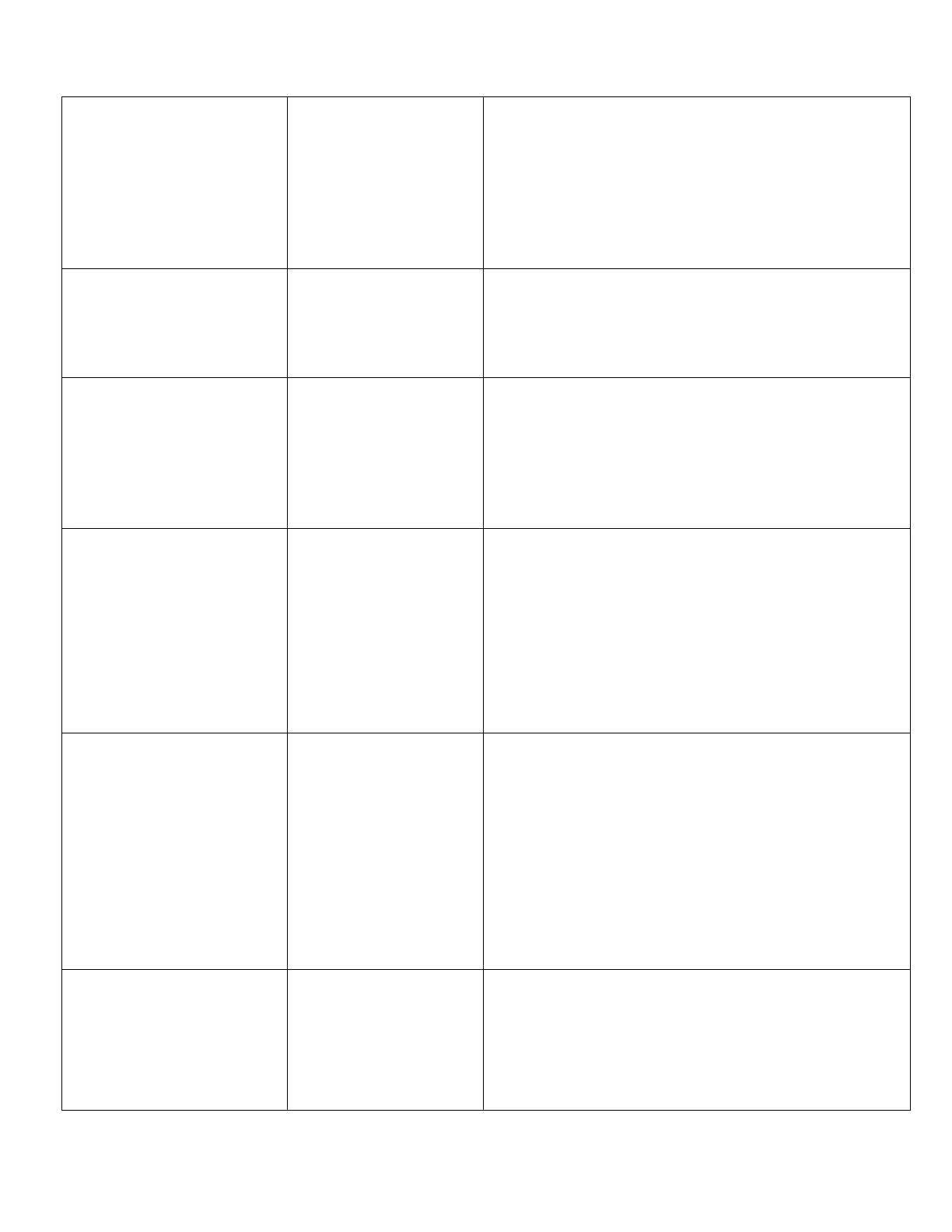

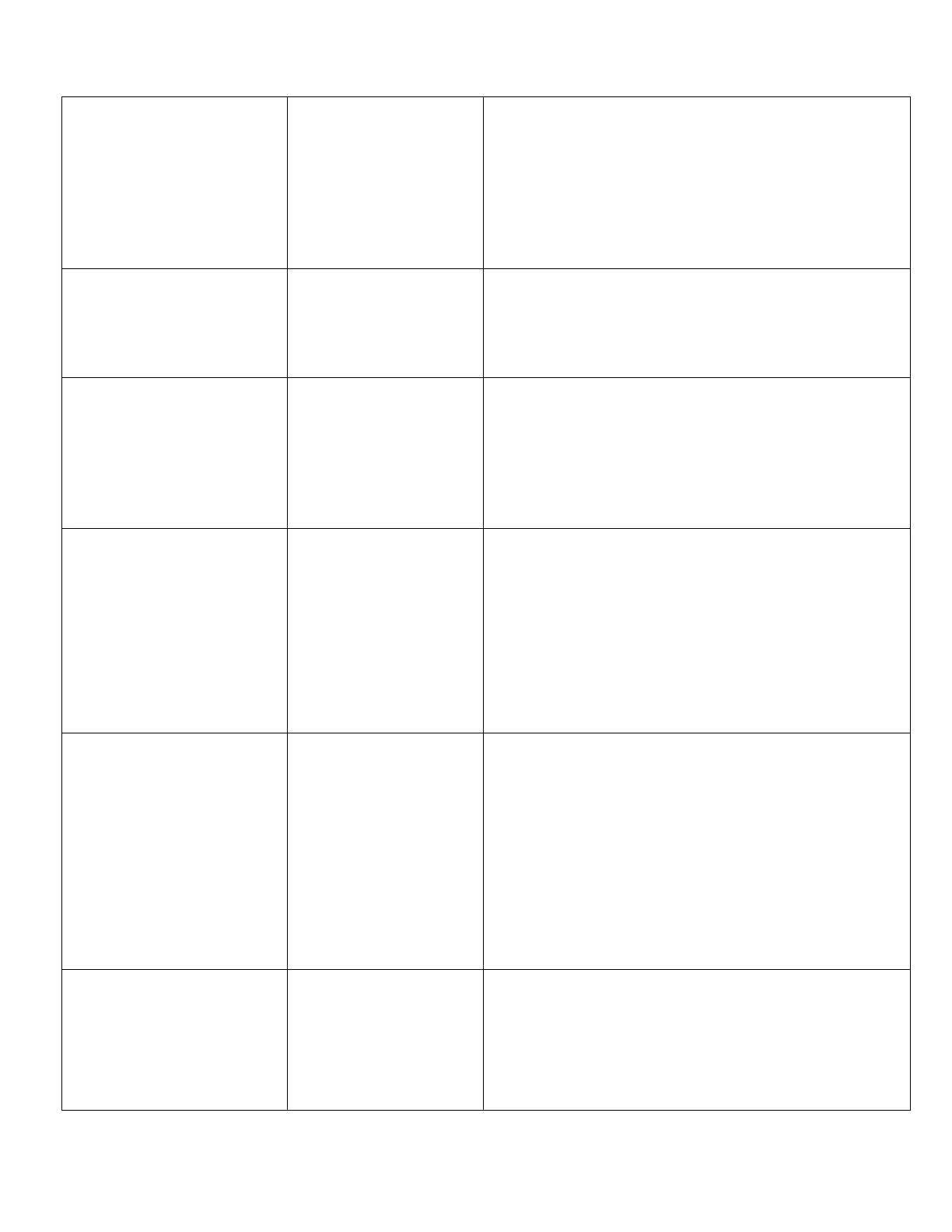

TROUBLESHOOTING GUIDE (CONTINUED)

Symptom Cause Correction

The machine stops, but the

red light does not come on.

NOTE: The last two bags

may be stapled together, or

caught in the Bag Closer.

The Model 125 Bag

Closer Limit Switch

did not release fast

enough.

Determine what is preventing the bags from passing

freely through the Bag Closer.

Are the filled bags rubbing the bottom Feed Plates of

the Bag Closer?

Is the take-away conveyor fast enough to prevent the

bags from contacting each other as they fall out of the

Bag Closer?

The machine stops, pushing

the Start Button indexes

one filled bag which passes

through the Bag Closer

without getting a staple.

The Model 125 Bag

Closer Limit Switch is

stuck in the actuated

position.

Make sure that the Limit Switch arm on the Model

125 moves freely.

The machine stops and the

film has not indexed far

enough. The Timing Mark

did not pass the Photo Eye

and no vertical heat seal

was formed.

The film advanced too

slowly because of

excess friction between

the Belt and the Fill

Opening.

Locate the cause of the friction.

Is the Water Injector functioning properly?

Is the Perforator cutting too deeply, allowing the

perforation to tear as it passes around the Fill

Opening, allowing direct contact between the Belts

and the Fill Opening?

The machine stops and the

film is broken, the film

breaks when the Dancer

Roller is pulled in against

the machine frame.

The film is not

unwinding from the roll

fast enough.

Locate the reason that the Dancer is not supplying the

film freely.

Make sure the Roll Holder spins easily when the

Brake Cam Limit Switch is depressed.

The Core Holder may be pressed too tightly into the

film core.

The Dancer Spring tension may need to be increased

by moving the Spring Bracket.

The machine stops and the

film has indexed too far

without forming the side

seal.

The Timing Mark

passes the Photo Eye

but did not see it.

Locate the reason that the Photo Eye did not see the

Timing Mark.

Does the Bag Film have a Timing Mark printed on it?

Is the Bag Film threaded between the Photo Eye and

the Reflector?

Is the Timing Mark passing above or below the Photo

Eye beam rather than through it?

Is the Photo Eye sensitivity set correctly for the

Timing Mark being used?

Side Seal not being formed

properly.

Film is sticking to the

Side Seal Bar or Teflon

Cloth.

Scrape off the Side Seal Bar.

Coat the Teflon Cloth with Dow Corning Paste #7.

Rotate the Teflon Cloth ¼ turn.

A rapid build-up of plastic on the Teflon Cloth

indicates that the Side Seal Bar may be too hot.

Loading...

Loading...