Why my Honeywell SPM Flex detector does not communicate via USB?

- JJeremy SchmidtSep 1, 2025

If your Honeywell Security Sensors detector does not communicate via USB, check the cable connection.

Loading...

Loading...

Why my Honeywell SPM Flex detector does not communicate via USB?

If your Honeywell Security Sensors detector does not communicate via USB, check the cable connection.

What to do if Honeywell Security Sensors Chemcassette cartridge door will not latch closed?

If your Honeywell Security Sensors Chemcassette cartridge door will not latch closed, make sure the Chemcassette cartridge is fully seated, the USB stick is not interfering with the door, the door is fully seated on both sides (latches should hook under the tabs easily), and all four latches are properly secured.

How to fix no blue light on Honeywell Security Sensors?

If your Honeywell Security Sensors shows no blue light, this could be due to no power to the detector. Turn the circuit breaker on and check the power cable.

What to do if Honeywell SPM Flex Security Sensors Chemcassette gate won’t open?

If your Honeywell Security Sensors Chemcassette gate won’t open, use either the Change Chemcassette wizard or Maintenance / Open/Close gate. If that doesn’t work, the gate motor may be broken, and you may need to replace the gate motor.

What to do if my Honeywell SPM Flex Security Sensors cannot achieve target flow rate?

If you cannot achieve the target flow rate on your Honeywell Security Sensors, confirm the inlet and outlet tubes are free of restrictions or kinks, and that all filters are clean. Also, confirm the Chemcassette cartridge is fully seated, and exit and re-enter the monitor to pull a fresh part of the tape. Check the filters (internal and external) and replace them as needed. Finally, confirm all tubing connections are properly seated (internal and external). If the pump is old, consider replacing it.

Why Chemcassette cartridge will not install properly in my Honeywell Security Sensors?

If your Honeywell Security Sensors Chemcassette cartridge will not install properly, confirm that the red shipping tab has been removed from the payout spool. Also, use the Change Chemcassette wizard to open the gate and guide you through the process, and confirm you are logged in with an account with the appropriate security level to change the Chemcassette cartridge.

What to do if my Honeywell SPM Flex unit will not read Chemcassette?

If your Honeywell Security Sensors unit will not read the Chemcassette, the cause may be a defective RFID chip. In this case, replace the Chemcassette.

Why does my Honeywell Security Sensors SPM Flex unintentionally turns on during transport?

If your Honeywell Security Sensors SPM Flex unintentionally turns on during transport, the cause may be that the physical power switch is on, unintentionally pushing the power switch by the display. To prevent this, put the physical power switch located behind the Chemcassette door in the off position. Place the switch back in the on position when ready to use again.

How to connect Honeywell Security Sensors SPM Flex to Ethernet network?

If your Honeywell Security Sensors SPM Flex is not on the Ethernet network, verify that the correct CAT5 cable is used and properly connected at both ends, and that the network port is active. If possible, use Auto detect configuration to automatically get IP configuration from the network. Otherwise, check the IP configuration and reboot.

Why Honeywell SPM Flex detector does not appear on the network?

If your Honeywell Security Sensors detector does not appear on the network, check the cable connection to the Ethernet port, keeping in mind that the system is for internal use only. Also, verify that the network configuration is enabled and consider using the “Auto...” setting.

| Brand | Honeywell |

|---|---|

| Model | SPM Flex |

| Category | Security Sensors |

| Language | English |

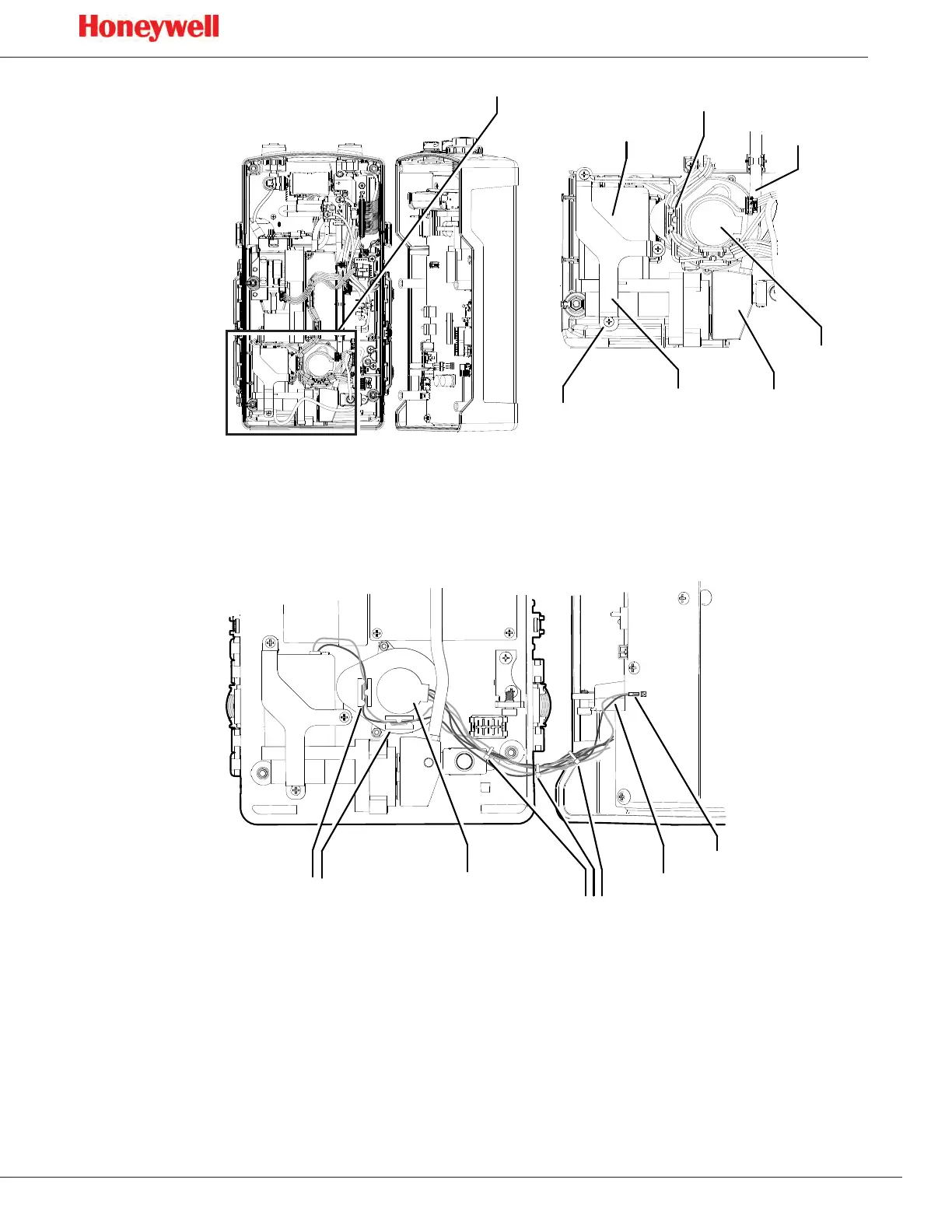

Details on fixed installation configuration and components.

Lists optional accessories for detector enhancement and functionality.

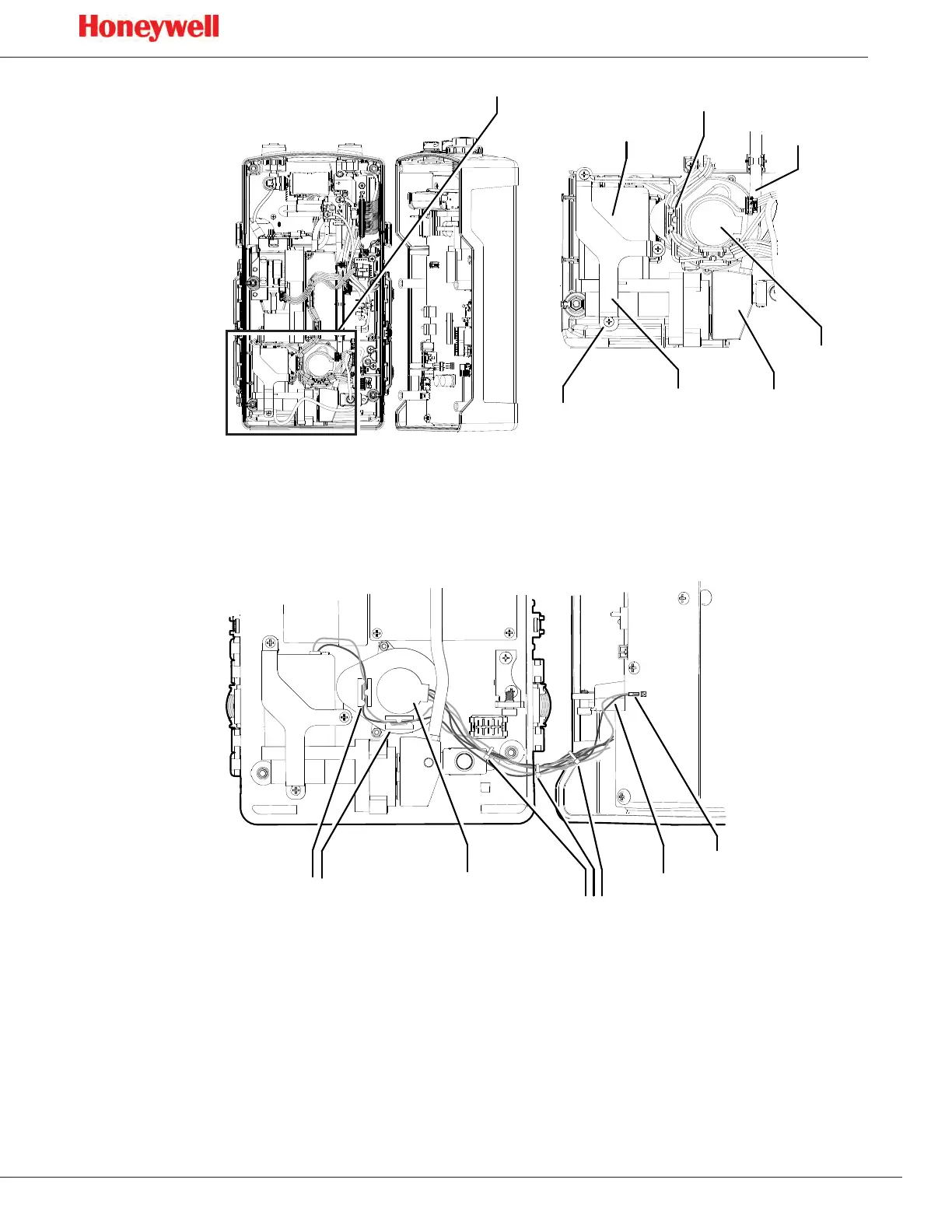

Describes common wiring configurations for fixed detector installations.

Details the Ethernet port and the internal terminal module for connections.

Illustrates various wiring diagrams for different configurations, including 4-20 mA.

Explains the three-wire connection for 4-20 mA output, including sink, source, and isolated.

Covers relay configuration and Modbus/TCP server capabilities for data communication.

Provides a detailed table of Modbus register addresses, bits, descriptions, and values.

Details sample and exhaust tubing specifications and calculations for optimal performance.

Provides technical drawings for detector installation, including dimensions and mounting.

Details the physical dimensions of the SPM Flex detector in inches and centimeters.

Describes available mounting bracket options for fixed detector installations.

Illustrates the standard mounting bracket and its installation dimensions.

Details the mounting bracket for replacing older SPM detector models.

Describes the sun shield for outdoor applications, protecting the detector from elements.

Explains how to rotate the display for optimal viewing in different installation orientations.

Procedure for converting a fixed installation detector into a portable unit.

Discusses the importance and types of in-line filters for detector protection.

Details the use and limitations of the optional sampling wand for specific gas detection.

Covers power-up sequence, battery status, and powering the detector off.

Explains the use of control buttons for menu navigation and operation.

Details the real-time clock, audible alarm settings, and status monitoring icons.

Describes how battery level and gas concentration are displayed on the detector.

Details how to enable or disable alarms and faults for specific periods.

Covers accessing event history, Chemcassette details, and gas settings.

Details network summary and additional status information like flow rate and battery.

Covers software versions and access to the maintenance menu functions.

Explains flow optimization and general setup configurations for the detector.

Discusses gas monitoring settings, latching options, and alarm volume.

Describes how to enable and configure Ethernet connection and Modbus TCP.

Details the detector's security levels and access rights based on passcodes.

Covers configuration manager, test menu options, and duty cycle settings.

Explains gas cross-sensitivity adjustment and stale tape fault management.

Provides a table of symptoms, causes, and corrective actions for common detector problems.

Lists and explains various instrument and maintenance fault codes.

Outlines recommended maintenance intervals and authorized service recommendations.

Step-by-step guide for replacing the end-of-line filter.

Procedures for checking pump functionality and verifying optic system response.

Instructions for removing and replacing internal dust and acid scrubber filters.

Detailed procedure for replacing the detector's pump assembly.

Guidance on diagnosing and resolving stepper and gate motor malfunctions.

Instructions for battery replacement and cleaning exterior surfaces.

Procedures for cleaning tape transport surfaces to prevent false readings.

Methods for verifying the integrity of tubing connections and detecting system leaks.

Guidelines for proper storage of the detector and end-of-life recycling.