Figures and Tables

Figure 1 Typical Power Supply and SCT/SFC Connections to ST 3000. ............................................ 6

Figure 2 Location of Failsafe Direction Jumper on PWA. .................................................................. 14

Figure 3 Write Protect Jumper Location and Selections.................................................................... 15

Figure 4 Typical Mounting Area Considerations Prior to Installation ................................................. 17

Figure 5 Typical Bracket Mounted and Flange Mounted Installations ............................................... 23

Figure 6 Leveling a Model STA122 or 922 Absolute Pressure Transmitter....................................... 27

Figure 7 Typical Flange Mounted Transmitter Installation ................................................................. 29

Figure 8 Typical Flush Mounted Transmitter Installation ................................................................... 30

Figure 9 Typical Pipe and Flange Mounted Installations ................................................................... 31

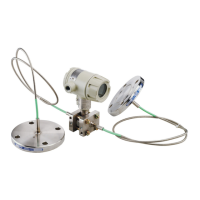

Figure 10 Typical Remote Diaphragm Seal Transmitter Installation.................................................... 33

Figure 11 Typical 3-Valve Manifold and Blow-Down Piping Arrangement. ......................................... 34

Figure 12 Typical Arrangement for ½” NPT Process Connection Piping............................................. 35

Figure 13 Operating Range for ST 3000 Transmitters......................................................................... 39

Figure 14 ST 3000 Transmitter Terminal Block ................................................................................... 40

Figure 15 Ground Connection for Lightning Protection........................................................................ 42

Figure A-1 Smart Meter Display with All Indicators Lit........................................................................... 52

Figure A-2 Typical Setup for Setting Range Values Using Local Zero and Span Adjustments. ........... 58

Table 1 Connecting Power Supply and SFC to ST 3000.................................................................... 6

Table 2 Testing Communications with Transmitter............................................................................. 7

Table 3 Verifying Transmitter’s Configuration Data (Using the SFC) ............................................... 10

Table 4 Cutting Failsafe Direction Jumper........................................................................................ 14

Table 5 Operating Temperature Limits (Transmitters with Silicone Fill Fluids) ................................ 18

Table 6 Transmitter Overpressure Ratings....................................................................................... 19

Table 7 Installing and Charging SFC Battery Pack........................................................................... 20

Table 8 Mounting ST 3000 Transmitter to a Bracket ........................................................................ 24

Table 9 Zero Corrects Procedure for STD110 .................................................................................. 28

Table 10 Mounting Remote Diaphragm Seal Transmitter .................................................................. 32

Table 11 Suggested Transmitter Location for Given Process ............................................................ 35

Table 12 Process Connections ........................................................................................................... 36

Table 13 Flange Description ............................................................................................................... 37

Table 14 Installing Flange Adapter ..................................................................................................... 38

Table 15 Wiring the Transmitter.......................................................................................................... 41

Table A-1 Smart Meter PushbuttonDescription .................................................................................... 52

Table A-2 Smart Meter Specifications. ................................................................................................. 53

Table A-3 Setting Range Values Using Local Zero and Span Adjustments ........................................ 54

Table A-4 Smart Meter Engineering Units Code .................................................................................. 60

Table A-5 Selecting Engineering Units ................................................................................................. 61

Table A-6 Smart Meter Restrictions for Setting Display Values ........................................................... 63

Table A-7 Setting Lower Display Values for Smart Meter Display ....................................................... 64

Table A-8 Setting Upper Display Value for Smart Meter Display ......................................................... 68

Table A-9 Setting Up Smart Meter Configuration Using an SFC ......................................................... 74

Table A-10 Summary of Typical Smart Meter Indications. ..................................................................... 80

Table A-11 Smart Meter Error Codes and Descriptions......................................................................... 81

Table B-1 Factory Mutual (FM) Approval.............................................................................................. 87

Table B-2 Canadian Standards Association (CSA) .............................................................................. 88

Table B-3 CENELEC / LCIE Certification ............................................................................................. 91

Table B-4 Standards Australia (LOSC) Certification ............................................................................ 92

Table B-5 Zone 2 (Europe) Declaration of Conformity ......................................................................... 92

Table B-6 NEMA Enclosure Type Numbers and Comparable IEC Enclosure Classification............... 94

vi ST 3000 Release 300 Installation Guide 2/05

Loading...

Loading...